Coaxial 3D printer nozzle and working method thereof

A 3D printer, coaxial nozzle technology, used in manufacturing tools, additive processing, ceramic molding machines, etc., can solve problems affecting product printing quality, troublesome operation, etc., to achieve easy implementation, save printing time, and improve printing. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

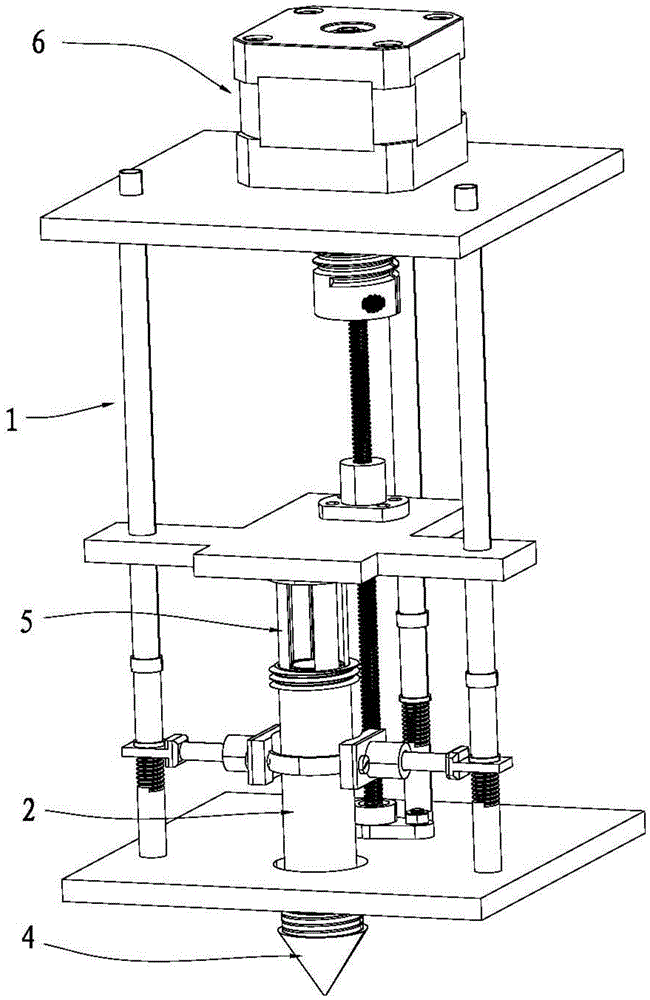

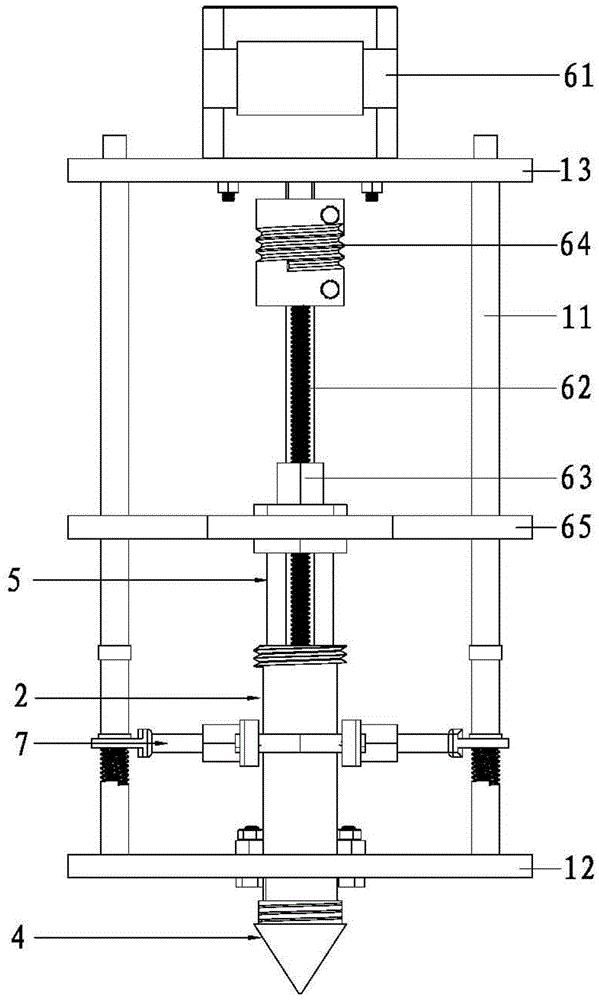

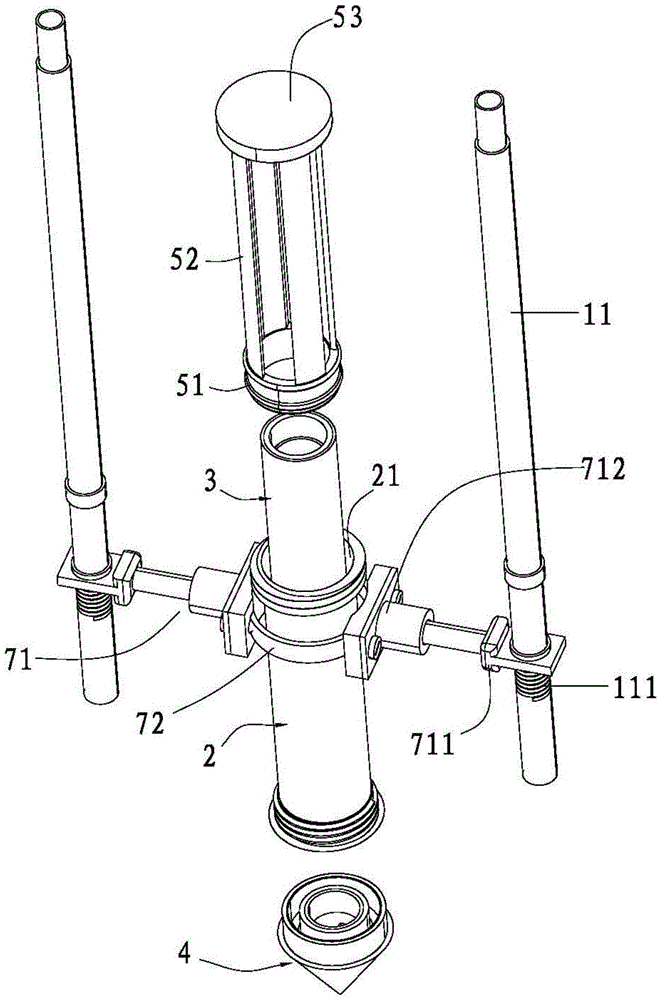

[0025] Example: see figure 1 , figure 2 with image 3 , a coaxial 3D printer nozzle provided by the present invention includes a bracket 1, an outer cylinder 2, an inner cylinder 3, a coaxial nozzle 4, an extrusion piston 5 and a linear drive device 6, and the outer cylinder 2 is vertically arranged on the bracket 1, the inner cylinder 3 is set in the outer cylinder 2, and a cylinder chamber 21 matching the extrusion piston 5 is formed between the outer wall of the inner cylinder 3 and the inner wall of the outer cylinder 2, and the coaxial The nozzle 4 is arranged at the lower end of the outer cylinder 2, and communicates with the inner cavity of the cylinder chamber and the inner cylinder 3 respectively, the extrusion piston 5 is movably arranged in the cylinder chamber, and the linear drive device 6 is arranged on the bracket 1 , and can drive the extrusion piston 5 to reciprocate in the cylinder cavity. The inner cylinder 3 is connected with the compressor.

[0026] s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com