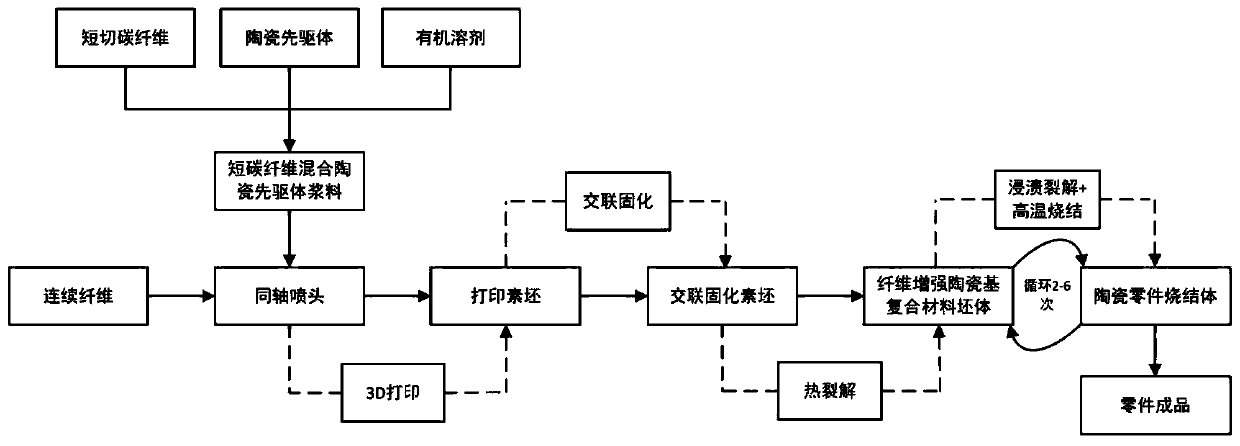

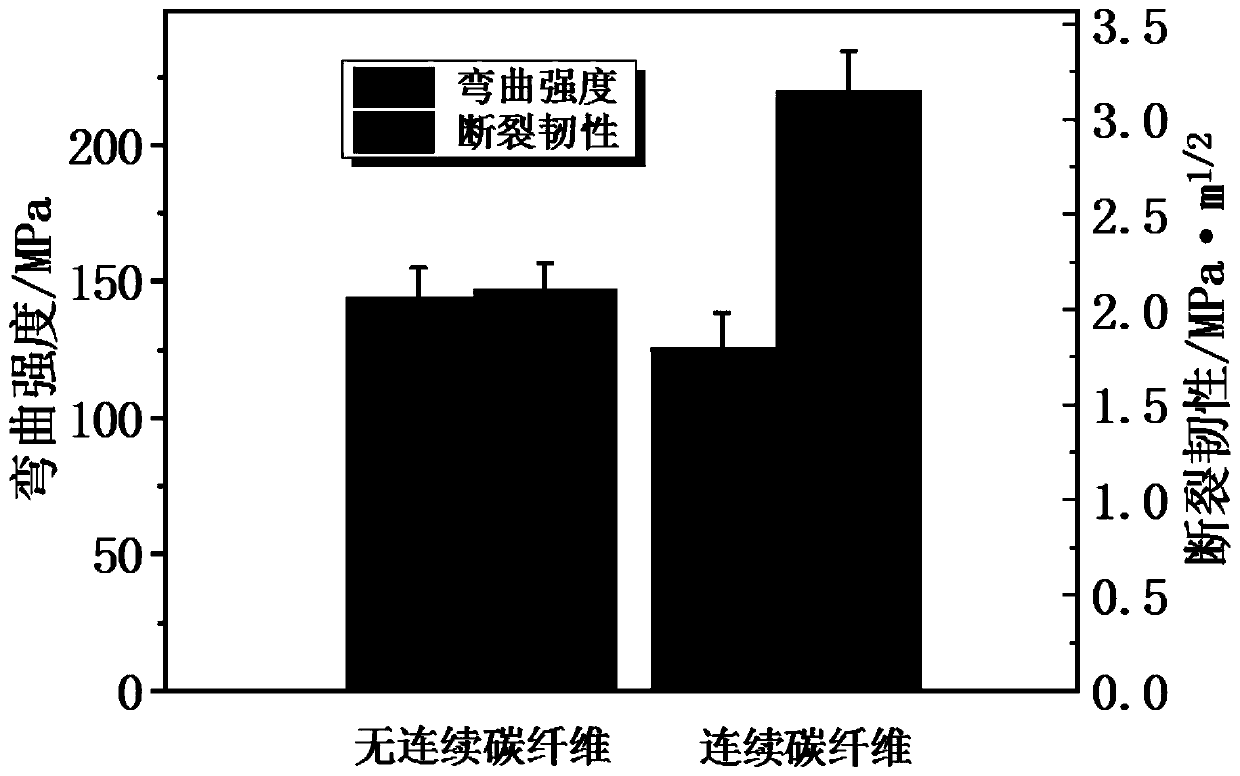

Method for forming continuous fiber-bonded short carbon fiber toughened ceramic matrix composite material

A short carbon fiber, continuous fiber technology, applied in the direction of additive processing, can solve the problems that the fiber and the ceramic matrix cannot be formed at the same time, the accuracy of the ceramic matrix composite material is limited, and the toughening effect is not good. The effect of molding and wide choice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

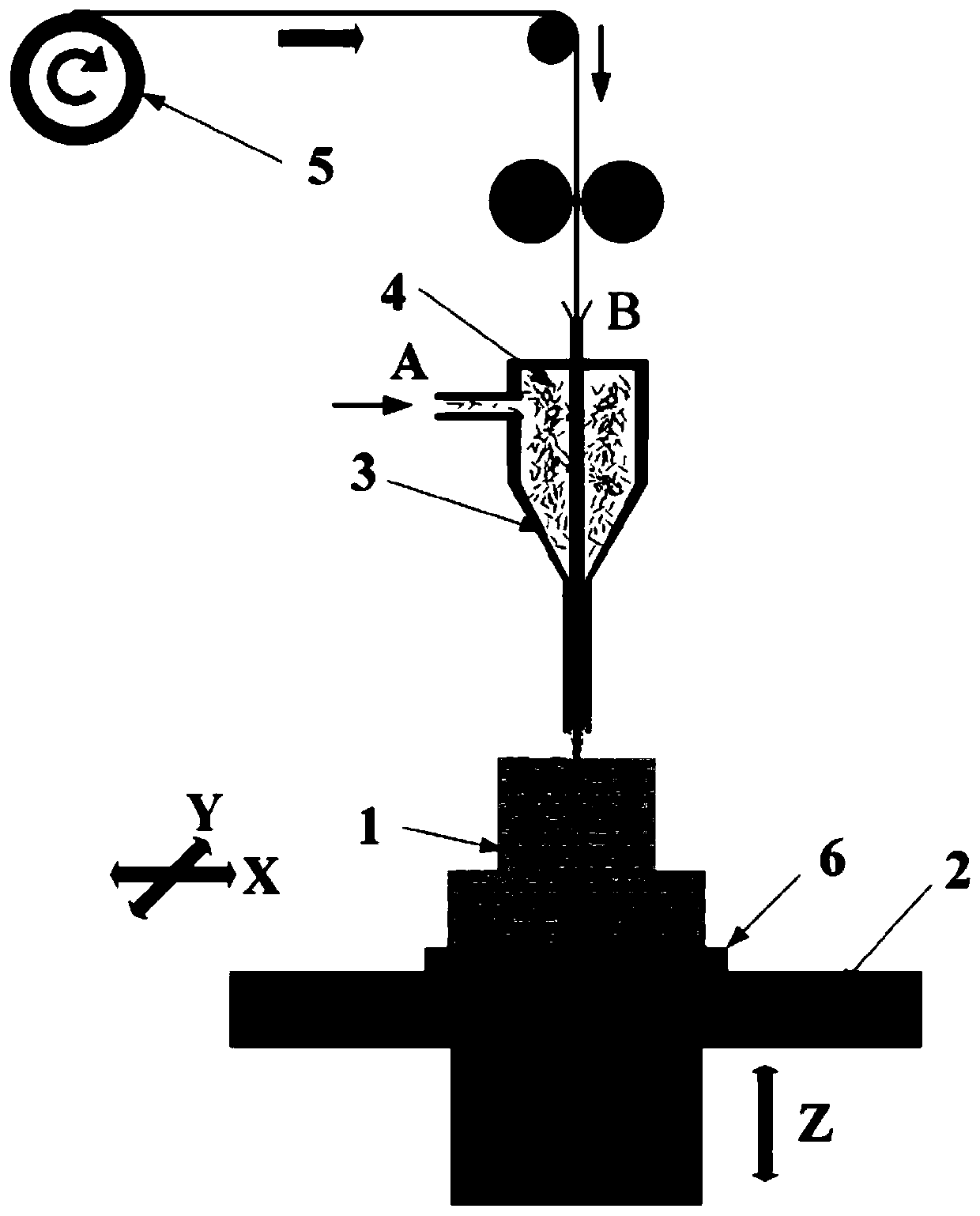

[0031] Step 1, dissolving polycarbosilane as a ceramic precursor in the organic solvent n-hexane to obtain a ceramic precursor solution with a mass fraction of the ceramic precursor of 50%, taking a ceramic precursor and chopped carbon fibers with a mass ratio of 4:5, Add chopped carbon fibers into the ceramic precursor solution, stir and evaporate the ceramic precursor solution, and obtain -1 Under the shear rate, the short carbon fiber mixed precursor slurry with a viscosity of 1000Pa s;

[0032] Step 2, centrifuge the short carbon fiber mixed precursor slurry at a speed of 1000r / min for 40 minutes to obtain the direct writing slurry, and then load it into the air pressure feeding device of the 3D printer;

[0033] Step 3: Install the glass fiber as a continuous fiber on the fiber conveying device, then place the beginning of the continuous fiber into the inner cylinder of the coaxial nozzle, and make it pass over the outlet of the coaxial nozzle, and the outer cylinder of t...

Embodiment 2

[0040] Step 1, dissolving polysiloxane as a ceramic precursor in an organic solvent mixed with cyclohexane, n-heptane, n-octane and petroleum ether to obtain a ceramic precursor solution with a mass fraction of ceramic precursor of 50%, taking A mass ratio of ceramic precursor and chopped carbon fiber is 10:5, the chopped carbon fiber is added to the ceramic precursor solution, the ceramic precursor solution is stirred and evaporated, and the obtained -1 Under the shear rate, the short carbon fiber mixed precursor slurry with a viscosity of 5000Pa s;

[0041] Step 2, centrifuging the short carbon fiber mixed precursor slurry at a speed of 3000r / min for 20 minutes to obtain the direct writing slurry, and then loading it into the pneumatic feeding device of the 3D printer;

[0042] Step 3, install carbon fiber and aramid fiber as continuous fiber on the fiber conveying device, then put the beginning of the continuous fiber into the inner cylinder of the coaxial nozzle, and make ...

Embodiment 3

[0049] Step 1, dissolving polysilazane as a ceramic precursor in toluene and xylene as an organic solvent to obtain a ceramic precursor solution with a mass fraction of a ceramic precursor of 50%, and taking a ceramic precursor with a mass ratio of 7:5 and chopped carbon fiber, the chopped carbon fiber is added to the ceramic precursor solution, the ceramic precursor solution is stirred and evaporated, and the obtained -1Under the shear rate, the short carbon fiber mixed precursor slurry with a viscosity of 3000Pa s;

[0050] Step 2: centrifuge the short carbon fiber mixed precursor slurry at a speed of 2000r / min for 30 minutes to obtain the direct writing slurry, and then load it into the pneumatic feeding device of the 3D printer;

[0051] Step 3, install polyaramid fiber and smart fiber as continuous fiber on the fiber conveying device, then put the beginning of the continuous fiber into the inner cylinder of the coaxial nozzle, and make it pass over the outlet of the coaxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com