Liquid film cooling injection rocket engine thrust chamber for rocket ramjet combined engine

A technology for ejecting rockets and engines, which is applied in rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems that the engine cannot work for a long time, the structure of the jacket cooling thrust chamber is complicated, etc., and achieves good atomization and mixing effect. , Simple and efficient structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

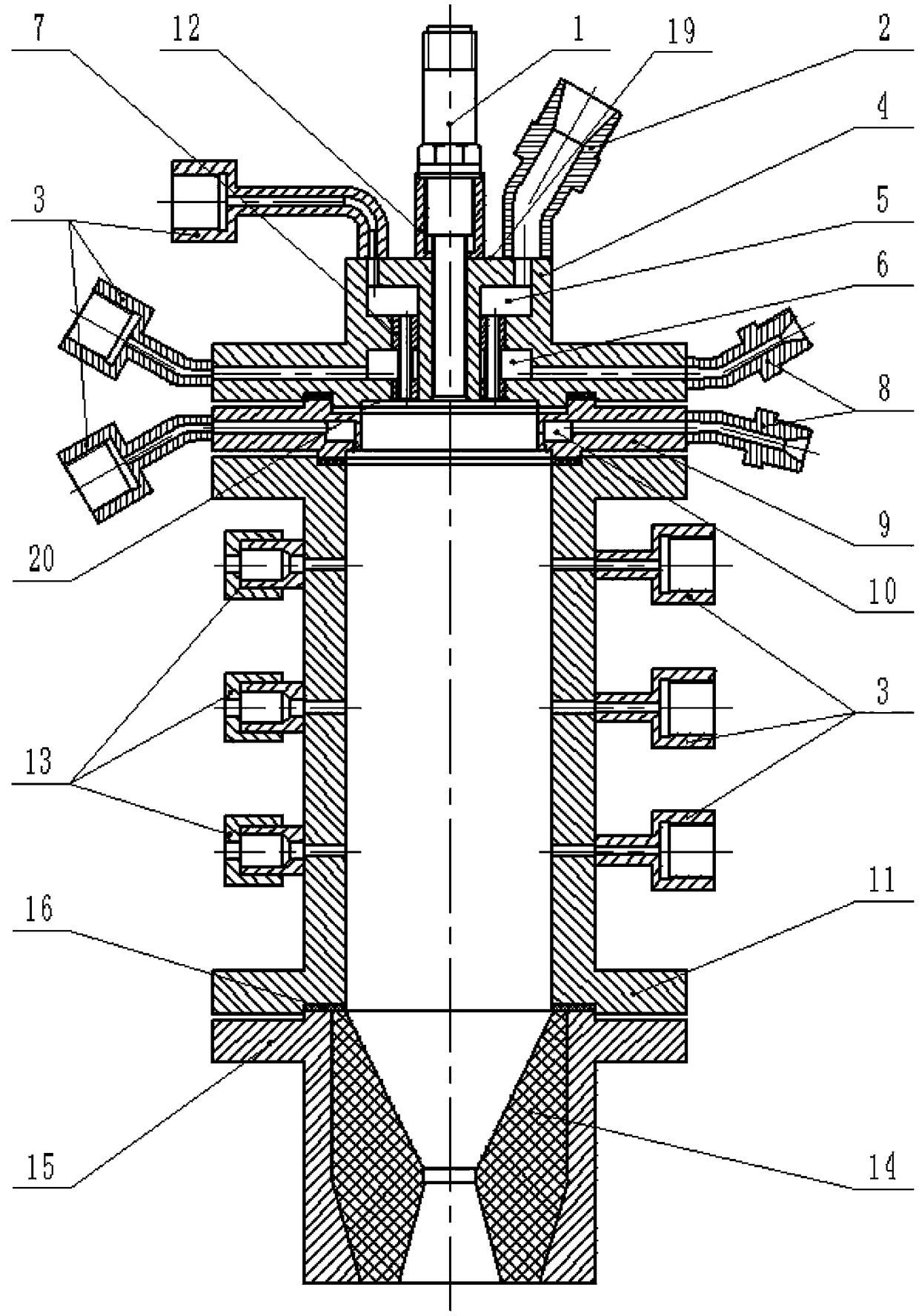

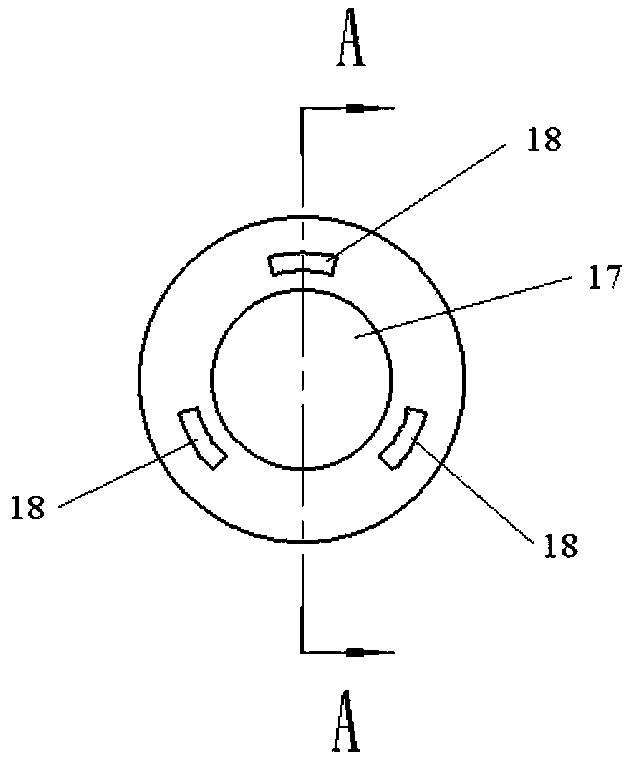

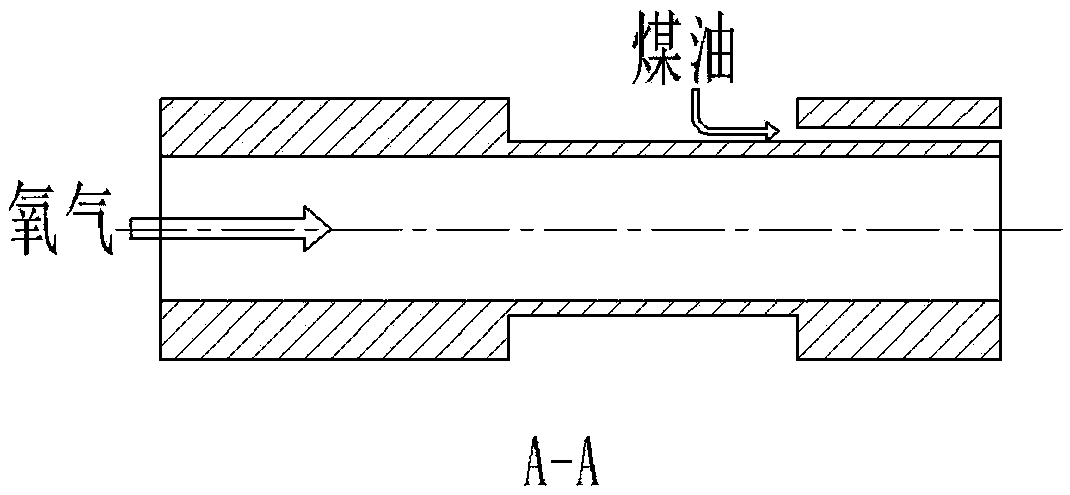

[0040] In the i experiment, the engine as a whole is figure 1 Assembled, including spark plug igniter 1, oxygen through joint 2, pressure measuring seat 3, head 4, gas-liquid coaxial nozzle 7, kerosene through joint 8, liquid film flange 9, thrust chamber shell 11, measuring The temperature seat 13 and the nozzle gland 15 are made of stainless steel 1Cr18Ni9Ti. Considering the harsh thermal environment of the throat, the nozzle is made of high-temperature-resistant graphite. The spark plug type igniter 1 and the spark plug seat of the head adopt the threaded connection of the thrust chamber 1 of the ejection rocket engine thrust chamber 1 of the M16 rocket stamping combined engine; 4 flanges, liquid film flanges 9, and the upper and lower flanges of the thrust chamber shell 11 have 8 equally spaced openings with a diameter of 13 mm, the wall thickness of the head flange is 20 mm, and the wall thickness of the remaining flanges is 15 mm; The liquid coaxial nozzle 7 is 29mm lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com