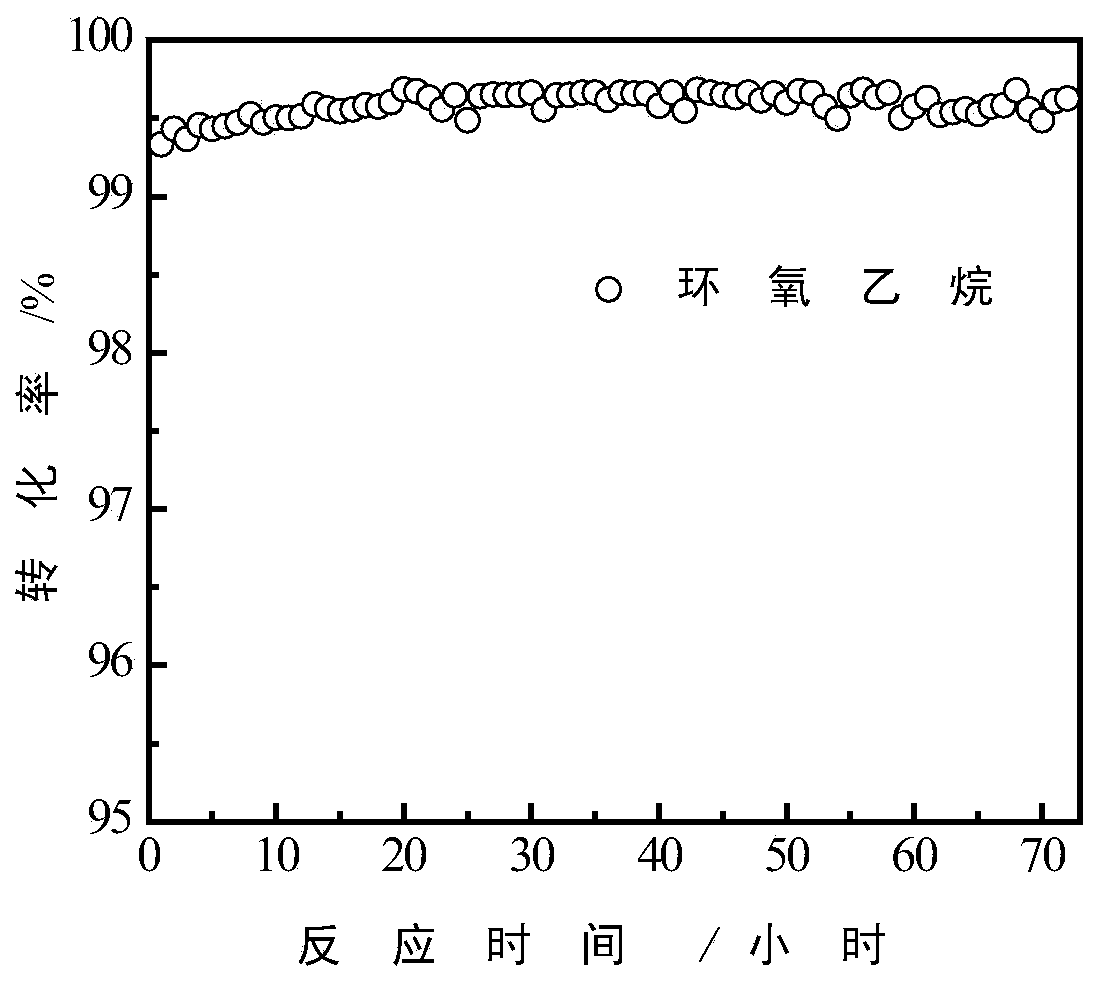

Ethylene oxide combustion catalyst with double active sites and production and application of ethylene oxide combustion catalyst with double active sites

A combustion catalyst and ethylene oxide technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, combustion method, etc., can solve problems such as hidden dangers, prone to explosion, high safety, etc. , to achieve strong thermal shock resistance and stability, simple and flexible preparation method, and excellent low-temperature activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

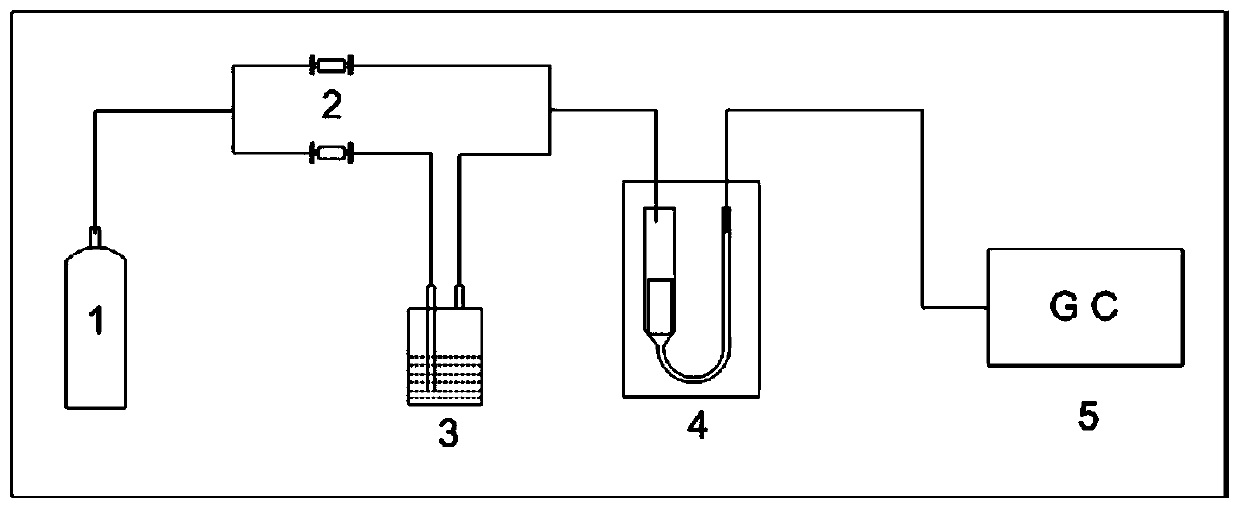

Method used

Image

Examples

Embodiment 1

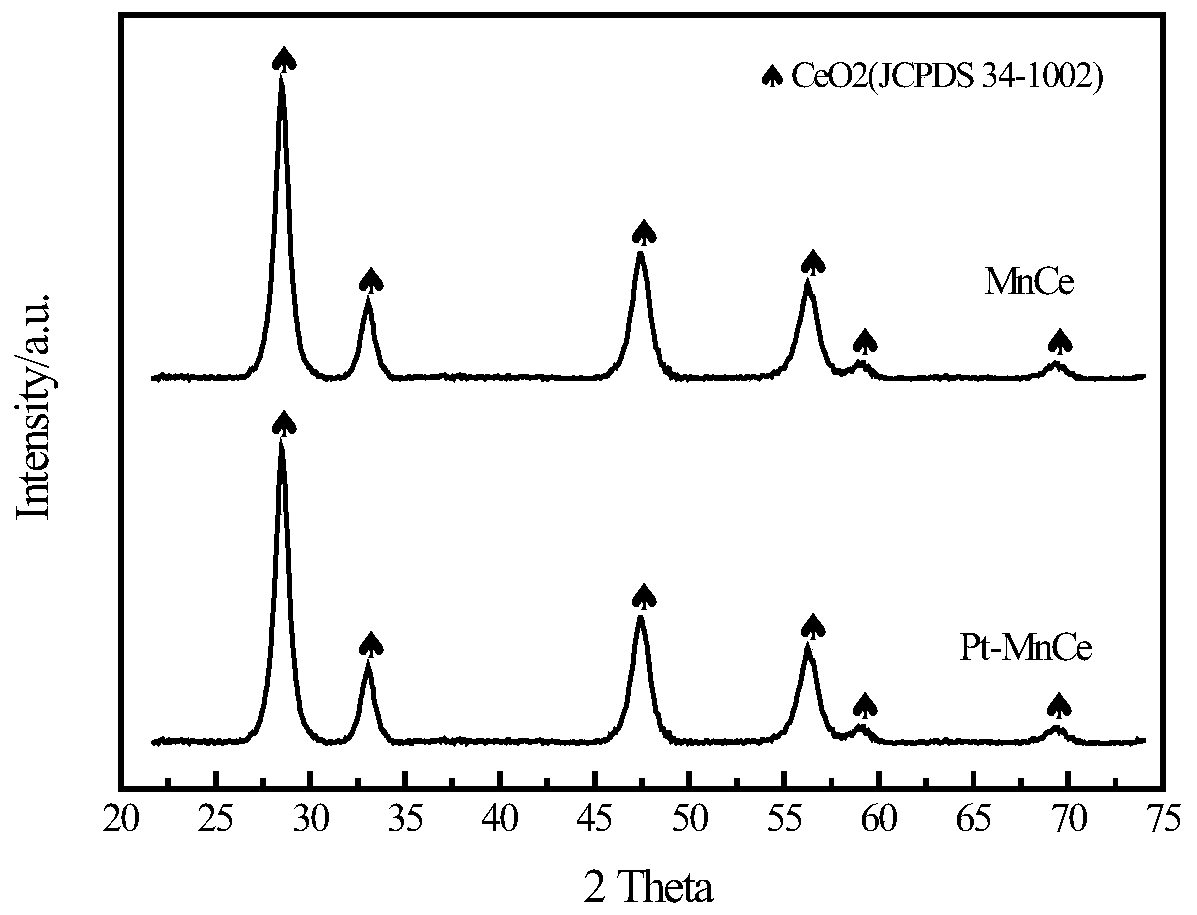

[0040] (1) Weigh 9.32g of Ce(NO 3 ) 3 ·6H 2 O powder and 5.98g of Mn(NO 3 ) 2 4H 2 O powder was added to a 50ml centrifuge tube, and then 40ml of deionized water was added. After dissolving and mixing evenly, 8.5246g of integral honeycomb cordierite was added and immersed at room temperature for 24 hours; centrifuged at 5000r / min for 10min to obtain precipitates a and above Clear a; take the precipitate a and put it in a vacuum drying oven at 100°C for 1 hour to dry until no water flows out, then put it in a muffle furnace and roast it at 400°C for 4 hours to obtain the precipitate a after roasting; cool the precipitate a after roasting After reaching room temperature, put it into the supernatant a and immerse at room temperature for 24 hours, centrifuge to obtain the precipitate b and supernatant b; take the precipitate b and dry it at room temperature until no water flows out, put it in a muffle furnace and bake it at 400°C for 4 hours to obtain the loaded MnCe Composit...

Embodiment 2

[0046] (1) Weigh 9.32g of Ce(NO 3 ) 3 ·6H 2 O powder, 5.98g of Mn(NO 3 ) 2 4H 2 Add O powder and 4.82g citric acid to a 100ml beaker, add 50ml deionized water, mix evenly, stir and evaporate in a water bath at 90°C to form a gel, then dry at 110°C for 6h to form a fluffy gel, and finally remove the formed gel The glue was placed in a muffle furnace and calcined at 400° C. for 4 hours to obtain 2.52 g of MnCe powder.

[0047] (2) Take by weighing 0.5g PVP (polyvinylpyrrolidone) as a dispersant, 0.05g sodium borohydride as a reducing agent, 200uL of 150g / L aqueous palladium chloride solution, add 40ml of deionized water, and stir for 30min to prepare Pd nanoparticles , washed twice with acetone and then fully shaken and mixed with 18ml of absolute ethanol to obtain 20.18g of uniformly dispersed Pd nano-sol, and the mass of metal palladium was 0.03g.

[0048] (3) Add 2.52g of MnCe powder to 20.18g of Pd nano-sol, evaporate to dryness in a water bath at 90°C, force the Pd na...

Embodiment 3

[0051] Weigh Mn(NO 3 ) 2 4H 2 O powder 3.84g and Ce(NO 3 ) 3 ·6H 2 O powder 10.46g, other operation is the same as embodiment 1, obtains Pd / MnCe catalyst 9.125g, is recorded as Pd / Mn 1 Ce 2 , the mass loading of Pd is 0.174%, the mass loading of Mn is 1.65%, and the mass loading of Ce is 3.21%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com