Three-dimensional spin-crossover gel material as well as preparation method and application thereof

A technology of spin-crossing and gel materials, applied in the field of spin-crossing complex materials, has achieved great application prospects, good energy performance, and simple and flexible preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Preparation of three-dimensional spin cross gel material

[0024] (1) Preparation of PVDF / PEG sol I: Put 0.45g polyethylene glycol (PEG, Mw~6000) into a 50mL three-neck flask at room temperature (20°C), pour 15mL N,N-di Methylformamide (DMF), ultrasonicated at 45°C and 40kHz for 10min until PEG was completely dissolved and became transparent, then added 2g of polyvinylidene fluoride (PVDF, Mw~50000), stirred at 300rpm for 2h until PVDF was completely dissolved and became transparent Transparent, obtain the mixed sol PVDF / PEG sol I of colorless and transparent PVDF and PEG;

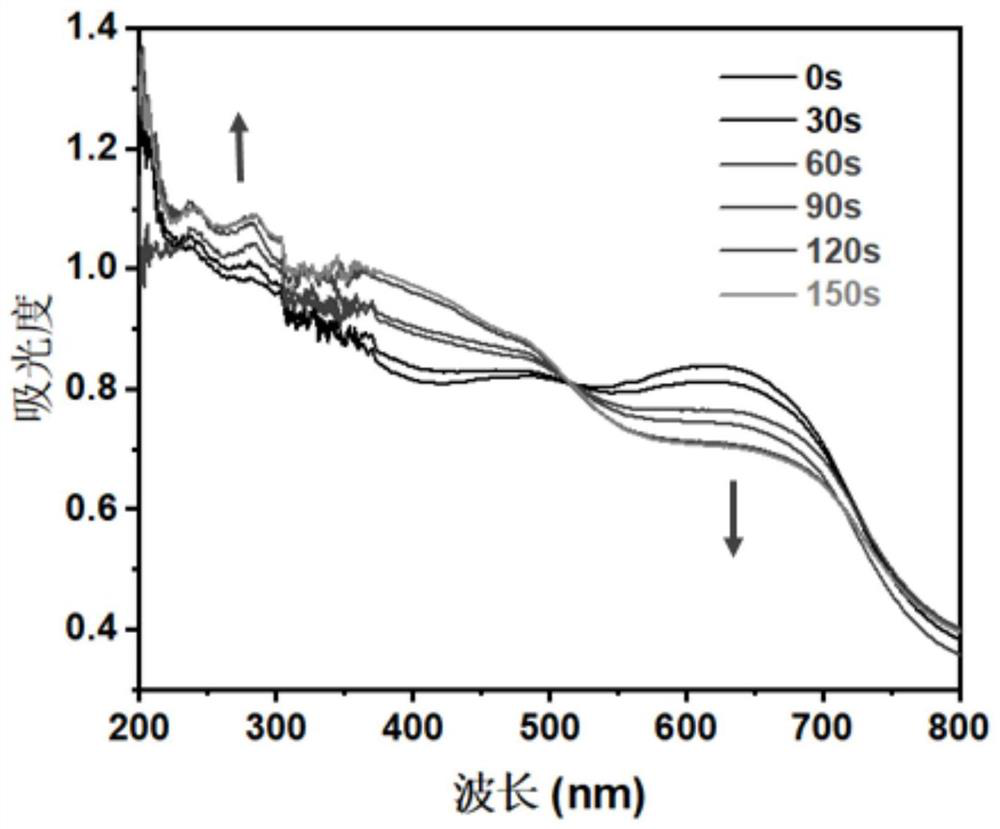

[0025] (2) 30 mg of two-dimensional spin cross complex [Fe(1,3-bpp) 2 (NCS) 2 ] 2 (Refer to Chinese patent 2018108260382 for the preparation method) and 6 mg up-conversion nanoparticles UCNPs (β-NaYF 4 :ErYb) was added to the PVDF / PEG sol I obtained in step (1), stirred for 1.5h, then transferred the flask to a 90°C oil bath and continued to stir for 8h at 300rpm until the two-dimensi...

Embodiment 2

[0029] Example 2: Preparation of three-dimensional spin cross gel material

[0030] (1) Preparation of PVDF / PEG sol I: put 0.2g polyethylene glycol (PEG, Mw~6000) into a 100mL three-neck flask at room temperature (15°C), pour 30mL N,N-di Methylformamide (DMF), ultrasonicated at 30°C and 60kHz for 5min until PEG was completely dissolved and became transparent, then added 4g of polyvinylidene fluoride (PVDF, Mw~50000), stirred at 500rpm for 3h until PVDF was completely dissolved and became transparent Transparent, obtain the mixed sol PVDF / PEG sol I of colorless and transparent PVDF and PEG;

[0031] (2) 15 mg of two-dimensional spin cross complex [Fe(1,3-bpp) 2 (NCS) 2 ] 2 (Refer to Chinese patent 2018108260382 for the preparation method) and 3mg up-conversion nanoparticles UCNPs (β-NaYF 4 : TmYb) was added to the PVDF / PEG sol I obtained in step (1), stirred for 0.5h, then transferred the flask to a 90°C oil bath and continued to stir for 6h at 100rpm until the two-dimensio...

Embodiment 3

[0034] Example 3: Preparation of three-dimensional spin cross gel material

[0035] (1) Preparation of PVDF / PEG sol I: Put 1 g of polyethylene glycol (PEG, Mw~6000) into a 50 mL three-neck flask at room temperature (25°C), and pour 10 mL of N,N-dimethylformamide into the flask Dimethyl formamide (DMF), ultrasonicated at 60°C and 20kHz for 20min until the PEG was completely dissolved and became transparent, then added 1g of polyvinylidene fluoride (PVDF, Mw~50000), stirred at 100rpm for 1h until the PVDF was completely dissolved and became transparent , obtain the mixed sol PVDF / PEG sol I of colorless and transparent PVDF and PEG;

[0036] (2) Mix 60 mg of the two-dimensional spin cross complex [Fe(1,3-bpp) under stirring condition of 500 rpm 2 (NCS) 2 ] 2 (Refer to Chinese patent 2018108260382 for the preparation method) and 12mg up-converting nanoparticles UCNPs (β-NaYF 4 :HoYb) was added to the PVDF / PEG sol I obtained in step (1), stirred for 1.5h, then transferred the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com