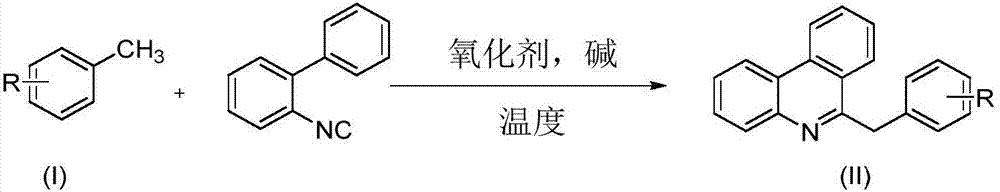

Synthetic method of 6-benzyl phenanthridine compounds

A technology of benzylphenanthridine and synthesis method, which is applied in the field of chemistry, can solve the problems of serious environmental pollution, dangerous raw material azide, harsh reaction conditions, etc., and achieve the effects of high reaction efficiency, easy post-processing, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

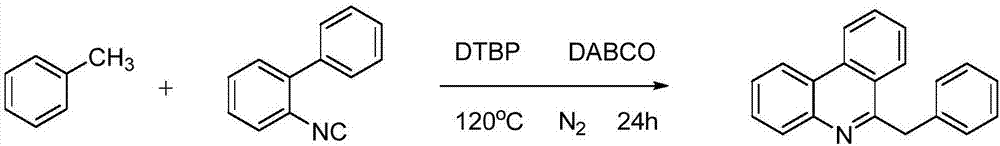

Embodiment 1

[0047] Synthesis of 6-benzylphenanthridine:

[0048]

[0049] At room temperature (25 °C), the reaction solvent toluene (2 mL) and a catalytic amount of organic base 1,4-diazabicyclo(2,2,2)octane (DABCO, 0.03 mmol, 0.1 equiv) were added to In the reaction tube, the reaction tube was continuously pumped-nitrogen 3 times, and then the oxidant di-tert-butyl hydroperoxide (DTBP, 0.75mmol, 2.5 equiv), the raw material toluene (2mL) and the raw material were continuously added to the reaction tube. 2-isocyanobiphenyl (0.3mmol, 1equiv), then stirred in an oil bath at a reaction temperature of 120°C for 24h, after the reaction was finished, the reaction solvent was directly spinned off, and column chromatography (300 mesh silica gel was filled in the column, The product was obtained after separation by using petroleum ether and ethyl acetate at a volume ratio of 40:1 as the eluent. The product was a yellow solid with a yield of 80%.

[0050] The data of the proton nuclear magnetic...

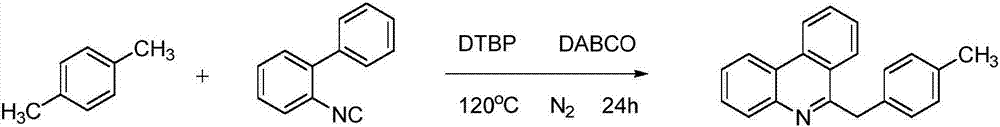

Embodiment 2

[0058] Synthesis of 6-(4-methylbenzyl)phenanthridine:

[0059]

[0060] At room temperature (25 °C), the reaction solvent p-xylene (2 mL) and a catalytic amount of the organic base 1,4-diazabicyclo(2,2,2)octane (DABCO, 0.03 mmol, 0.1 equiv) Join in the reaction tube, the reaction tube is continuously carried out 3 times pumping-nitrogen gas operation, then continue to add oxidant di-tert-butyl hydroperoxide (DTBP, 0.75mmol, 2.5equiv), raw material p-xylene ( 2mL) and raw material 2-isocyanobiphenyl (0.3mmol, 1equiv), then stirred in an oil bath at a reaction temperature of 120°C for 24h. 300 mesh silica gel, petroleum ether and ethyl acetate volume ratio 40:1 as the eluent) were separated to obtain the product, the product was a yellow solid, and the yield was 78%.

[0061] The data of the proton nuclear magnetic resonance spectrum of gained product are as follows:

[0062] 1 H NMR (500MHz, CDCl 3 )δ8.58(1H,d),8.52(1H,d),8.18-8.20(m,2H),7.71-7.76(m,2H),7.61-7.64(m,1H),7...

Embodiment 3

[0069] Synthesis of 6-(3-methylbenzyl)phenanthridine:

[0070]

[0071] At room temperature (25 °C), the reaction solvent m-xylene (2 mL) and a catalytic amount of the organic base 1,4-diazabicyclo(2,2,2)octane (DABCO, 0.03 mmol, 0.1 equiv) Join in the reaction tube, the reaction tube is continuously carried out 3 times of pumping-nitrogen gas operation, then continue to add oxidant di-tert-butyl hydroperoxide (DTBP, 0.75mmol, 2.5equiv), raw material m-xylene ( 2mL) and raw material 2-isocyanobiphenyl (0.3mmol, 1equiv), then stirred in an oil bath at a reaction temperature of 120°C for 24h. 300 mesh silica gel, petroleum ether and ethyl acetate volume ratio 40:1 as the eluent) to obtain the product after separation, the product is a yellow solid, the yield is 73%.

[0072] The data of the proton nuclear magnetic resonance spectrum of gained product are as follows:

[0073] 1 H NMR (500MHz, CDCl 3 )δ:8.59(d,1H),8.54(d,1H),8.18-8.22(m,2H),7.72-7.77(m,2H),7.62-7.66(m,1H),7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com