Method for producing natural fragrance smoked knitting wool

A manufacturing method and technology of natural flavors, applied in the field of wool manufacturing, can solve the problems of complicated process, no longer having fragrance, slowing down the release speed of flavor, etc., and achieve the effect of simple operation and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

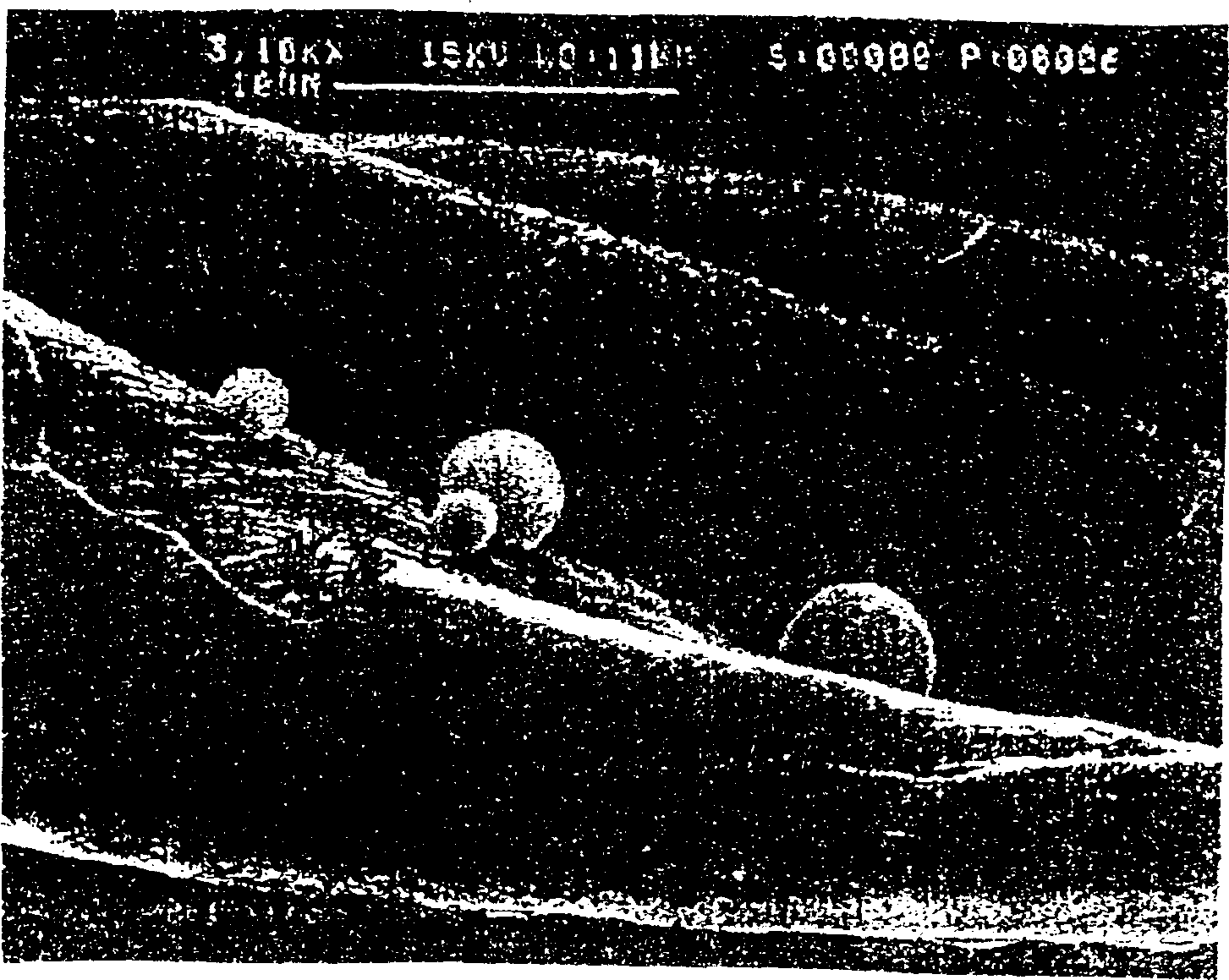

Image

Examples

Embodiment Construction

[0029] The manufacture method of the natural scented wool of the present invention is to add spices after the dyeing process of the wool, and the process steps of the wool are as follows:

[0030] (1) Put the dyed wool into a dye vat filled with a treatment solution, the temperature of the treatment solution is room temperature, and the weight of the wool and the treatment solution is about 1:30;

[0031] (2) Add an appropriate amount of acetic acid to the treatment solution to adjust the pH value of the treatment solution to about 5.5;

[0032] (3) After adding acetic acid, run for about 5 minutes, then add a cross-linking agent accounting for about 25% of the weight of the fragrance to the mixture of the wool and the treatment solution, and the cross-linking agent is a water-insoluble adhesive;

[0033] (4) Run for about 5 minutes after adding the cross-linking agent, and raise the temperature of the mixture of wool and treatment solution to about 45°C at a rate of about 2°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com