Enzymatic beating process for natural-color bagasse pulp

A technology of bagasse pulp and natural color, which is applied in the direction of pulp beating method, etc., to achieve the effect of mild conditions, low production cost and high enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

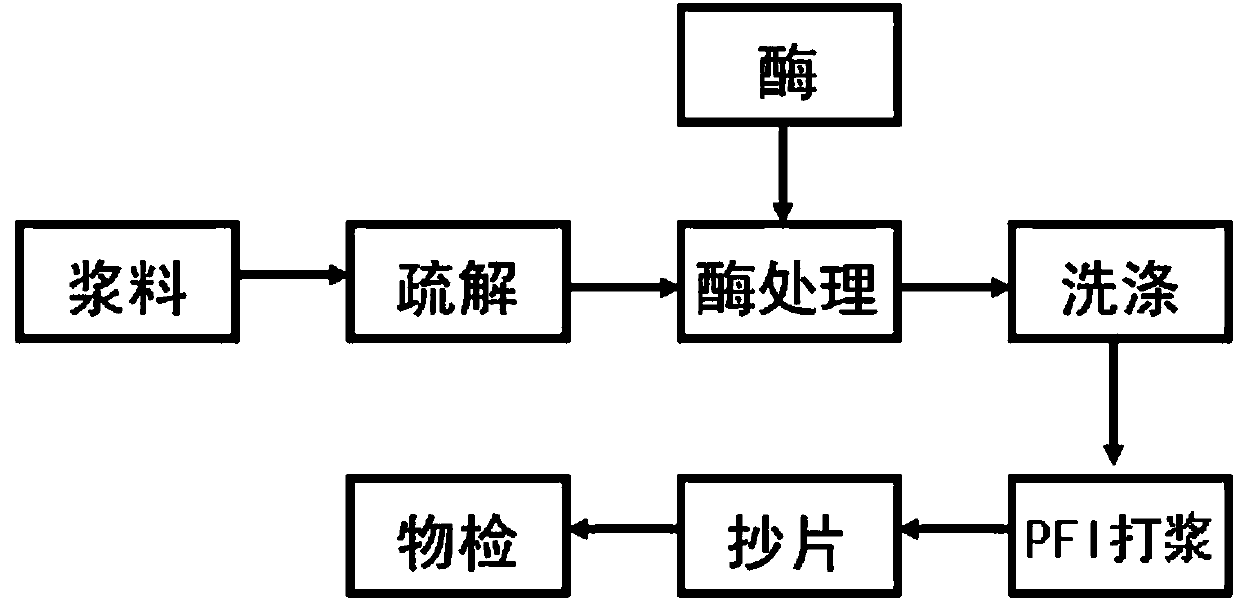

[0021] like figure 1 As shown, the inventor carried out enzymatic beating treatment to the unbleached bagasse pulp provided by Nanning sugar paper factory in the laboratory.

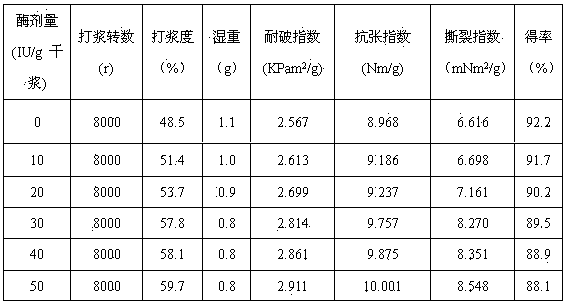

[0022] Using unbleached bagasse pulp provided by Nanning Sugar Paper Factory as raw material, high-frequency deflaking machine is used, pulp feeding pressure is 0.15-0.2MPa, rotor speed is 2000-3000r / min, and purification equipment is equipped at the paddle inlet. For 30-90 minutes, according to the enzyme dosage of 0, 10, 20, 30, 40 and 50 (IU / g dry pulp), the pulp volume is 35g dry pulp, the pulp concentration is 5%, the pH value is 6.0, and the temperature is 50°C. Slurry for 60 minutes, during the process, rub the polyethylene bottle by hand every 20 minutes to ensure the uniform mixing of enzyme and pulp. After the reaction is complete, thoroughly wash the pulp, and use ZQS7-PFⅠ vertical refiner for beating respectively. rpm. After the beating is completed, the slurry is thoroughly washed, and ...

Embodiment 2

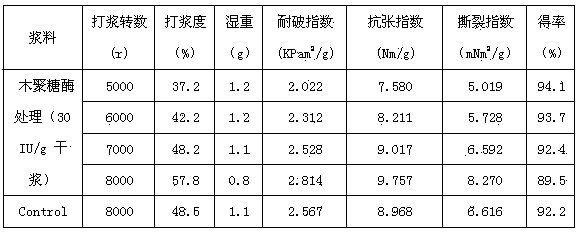

[0033] Example 2 Analysis of energy consumption in the beating process of natural color bagasse pulp treated with xylanase

[0034]At the same time, the inventors analyzed the energy consumption of the beating process treated under the dosage of xylanase 30 IU / g dry pulp. The specific method is: under the conditions of pulp volume 35g dry pulp, pulp concentration 5%, pH value 6.0, temperature 50°C The pulp was treated separately for 60 minutes. During the treatment, the polyethylene bottle was rubbed by hand every 20 minutes to ensure the uniform mixing of the enzyme and the pulp. After the reaction is completed, thoroughly wash the slurry, and use a ZQS7-PFⅠ vertical refiner to perform beating at 5000, 6000, 7000, and 8000 revolutions respectively. The beating concentration is 10%, and the gap between the beating roller and the beating chamber is 0.2mm. The pressure is 3.4N·mm -1 . After the beating is completed, the slurry is thoroughly washed, and the yield, beating degre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com