Patents

Literature

294results about How to "Mild reaction temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

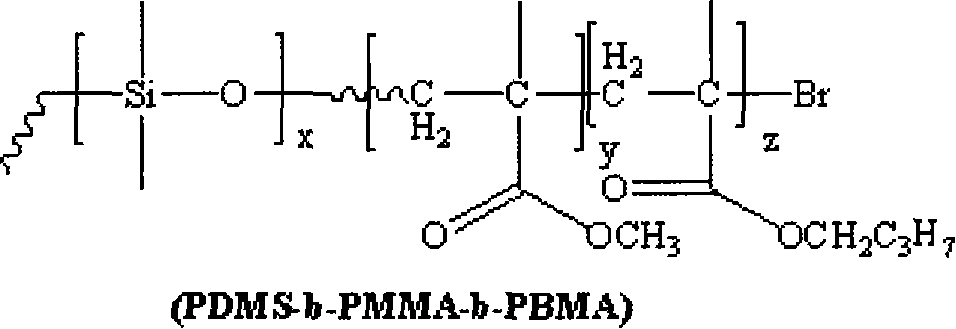

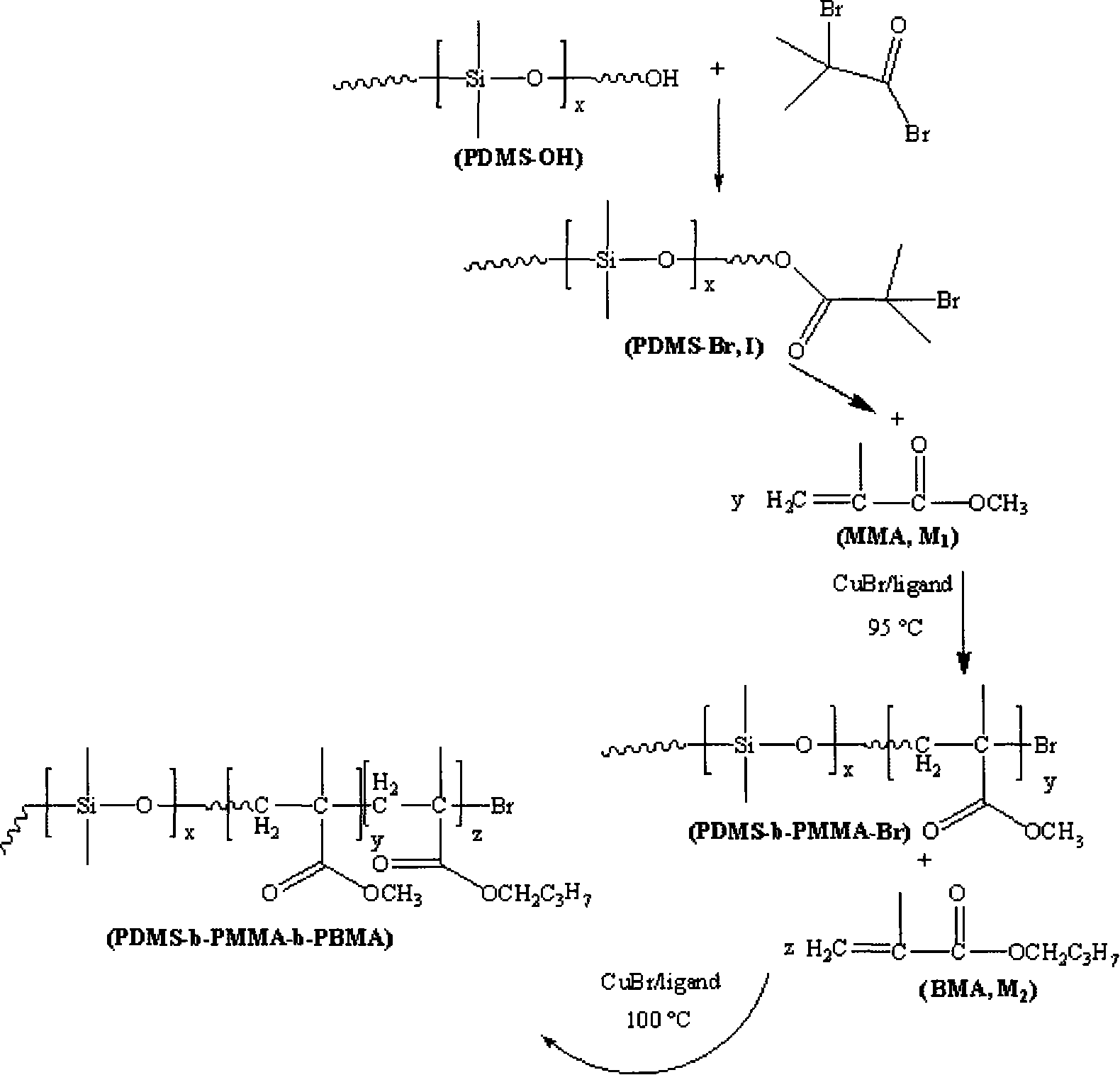

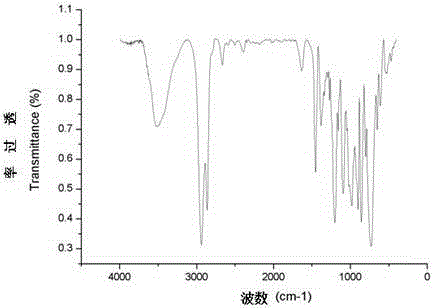

Silicon-acrylic tri-block copolymer with low surface energy and preparing method thereof

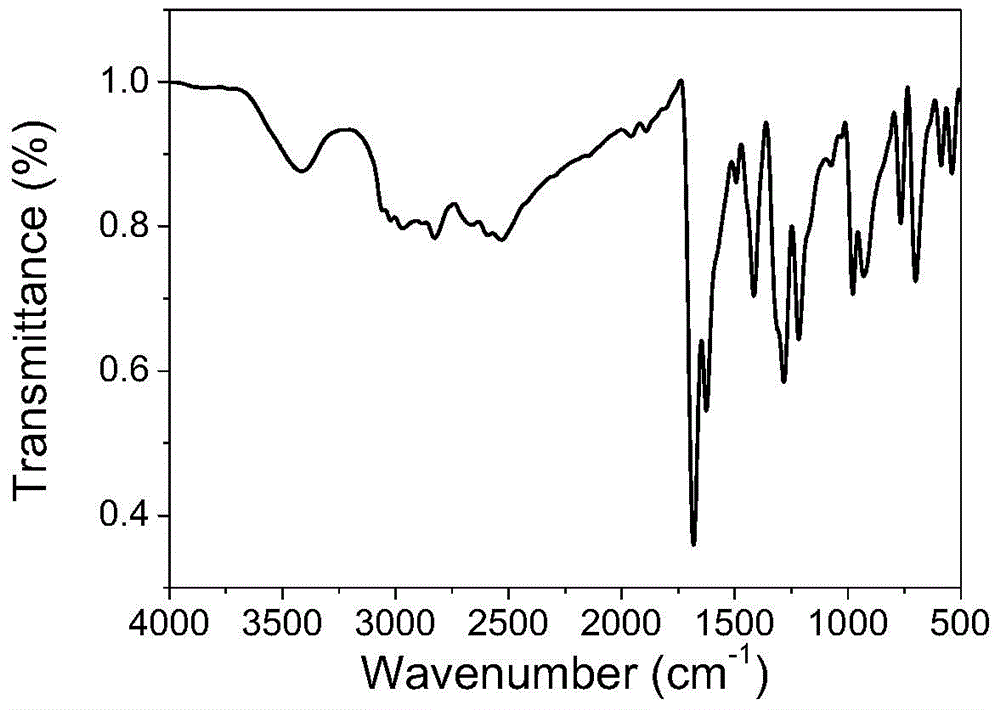

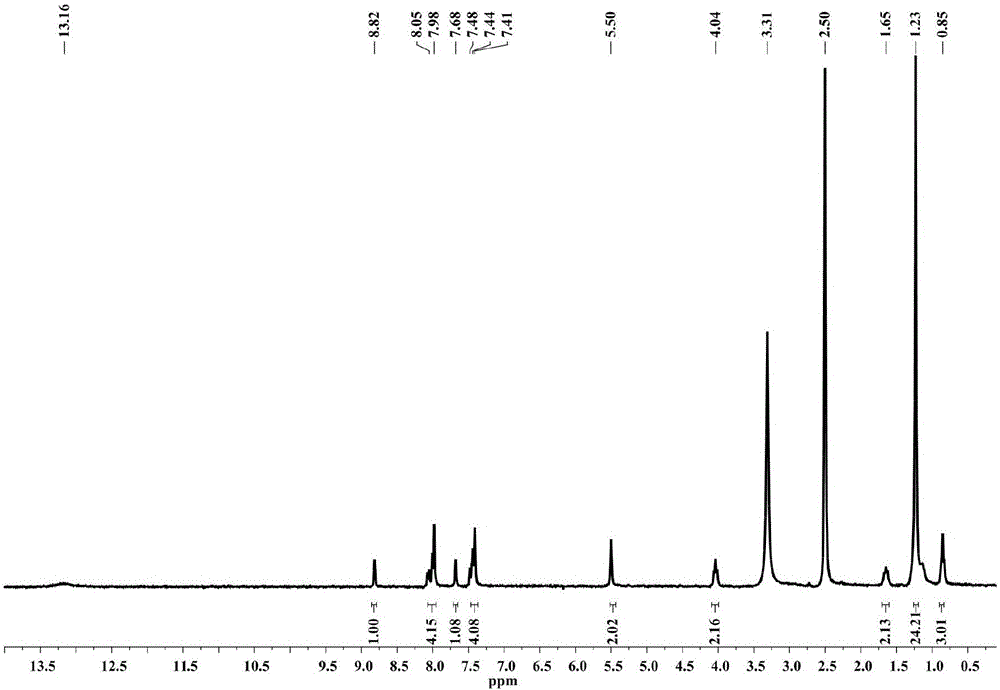

The invention relates to a silicon-acrylic three-block copolymer with low surface energy and a process for preparation, which relates to the synthesis of silicon-acrylic low-surface-energy three-block copolymer. The invention provides a silicon-acrylic three-block copolymer with low surface energy, whose structure of reaction product is accurate, and the original skeleton construction of each block is kept. The invention relates to a dimethyl silicone polymer-b- polymethyl methacryate-b-poly n-butyl methacrylate. And the process for preparation comprises first, preparing dimethyl silicone polymer macromolecule initiating agent of the dead ends of bromine atoms, second, preparing two-block macromolecule initiating agent of copolymer dimethyl silicone polymer-b-polymethyl methacryate, third, preparing two-block copolymer macromolecule initiating agent of dimethyl silicone polymer-b- polymethyl methacryate, finally, preparing three-block novel copolymer of dimethyl silicone polymer-b- polymethyl methacryate-b-poly n-butyl methacrylate.

Owner:XIAMEN UNIV

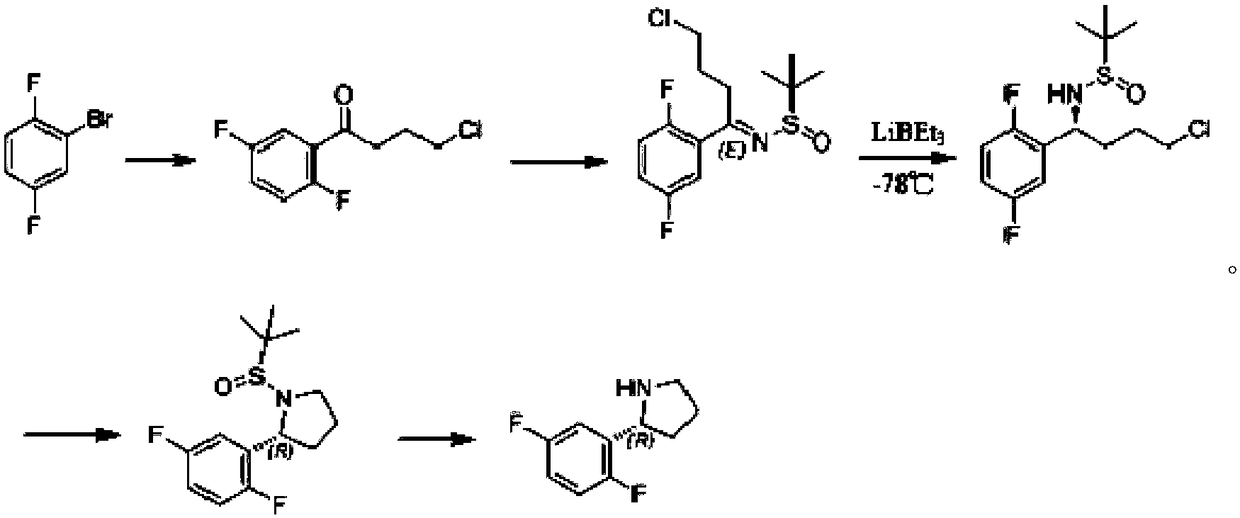

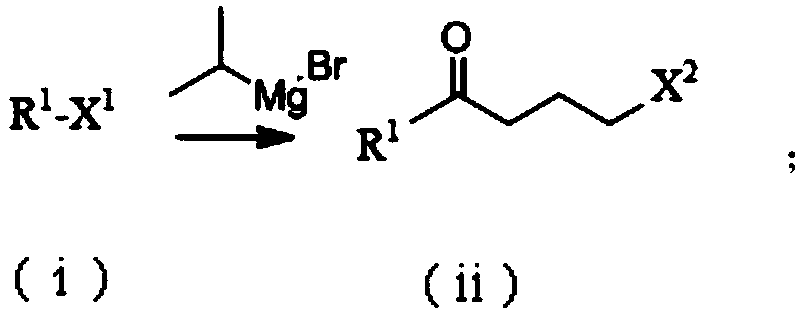

Synthesis process of chiral pyrrolidine and intermediates

The invention discloses a synthesis process of chiral pyrrolidine and intermediates. The synthesis process adopts 2, 5-difluorohalobenze or 5-fluoro-3 halogenated pyridine as the raw material substrate, and employs a chiral catalyst to induce chiral reaction so as to reduce a ketone compound into a corresponding chiral alcohol compound, and then carries out substitution reaction to introduce an easily leavable group to an alcoholic hydroxyl group so as to facilitate ring formation reaction (or carry out ring formation reaction directly). The process provided by the invention has the advantagesof significant increase of product yield and reduction of cost, also the reaction temperature is mild, and the process is easy to control and industrialize.

Owner:上海鑫凯化学科技有限公司

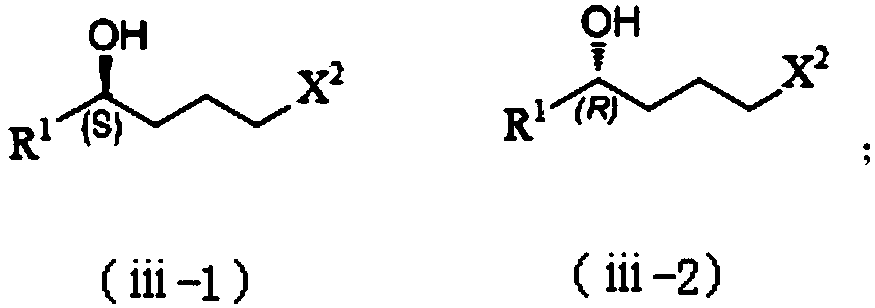

Preparation method of hydrofluoroether

InactiveCN103739450AInhibitionEasy to purifyEther preparation by compound additionReaction temperatureDouble bond

The invention relates to a preparation method of hydrofluoroether. The preparation method comprises the following steps: (1), dissolving an alkali compound in fluorine-containing alkanol, adding a solvent, adding fluorinated olefin, and heating and stirring for reaction to obtain a mixed solution; (2), washing the mixed solution obtained in the step (1) by using water, standing for demixing, collecting an organic phase solution of a lower layer, and rectifying to obtain a hydrofluoroether product. According to the preparation method, the generation of double-bond impurities can be inhibited, and a reaction product from which a target product is easily purified can be obtained; the reaction temperature and the reaction pressure are relatively mild, the safety coefficient is high, and more satisfactory reaction speed can be obtained; the solvent is easily recycled, the cost is lowered, and a plurality of wastes are prevented from polluting the environment.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

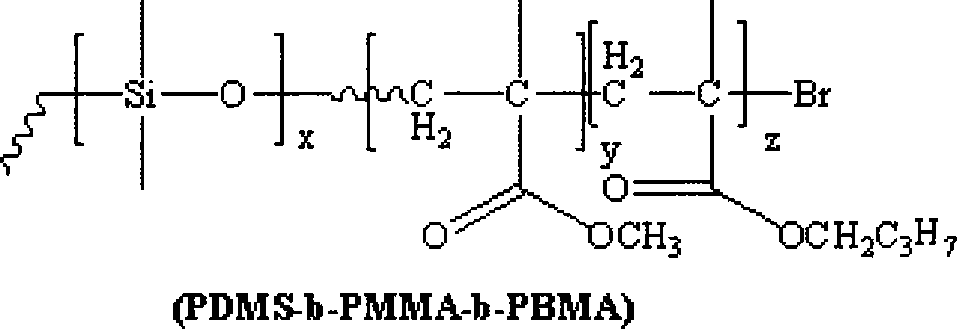

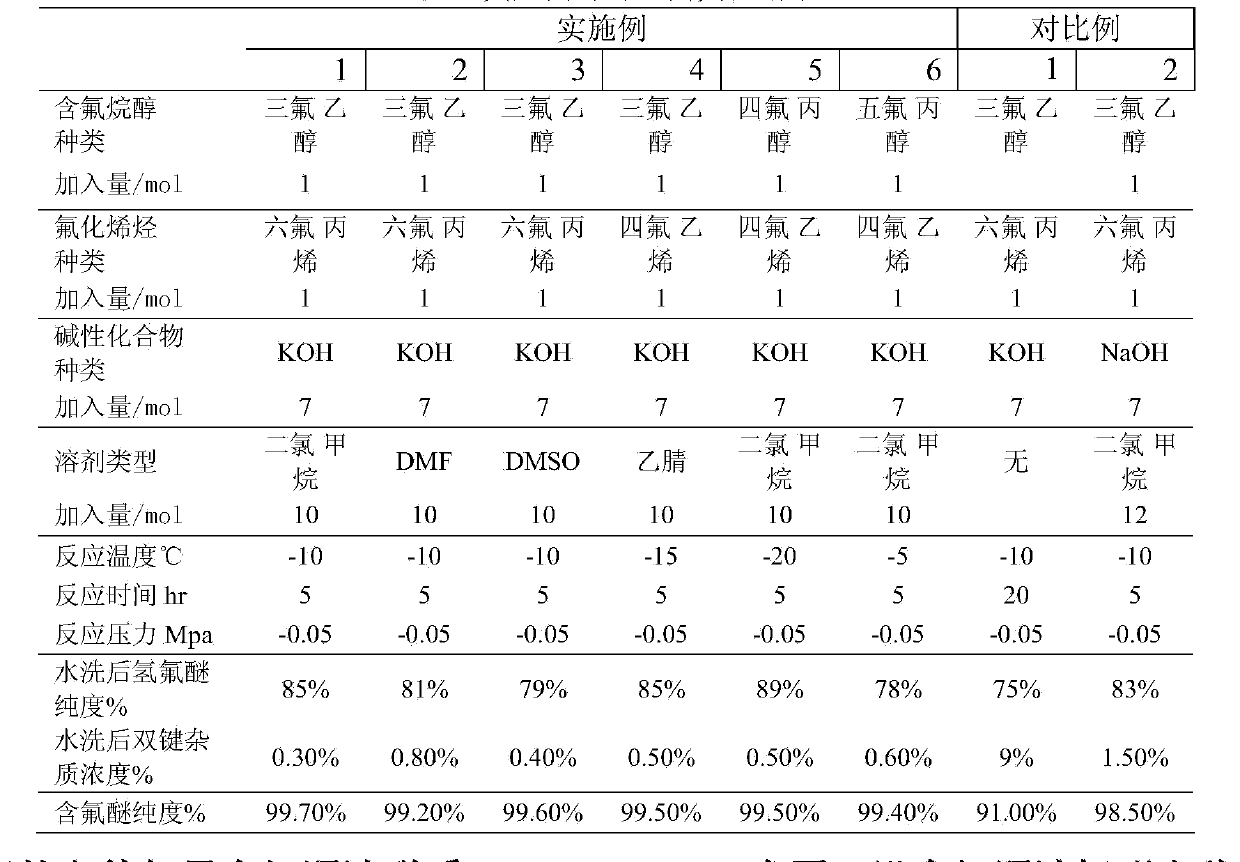

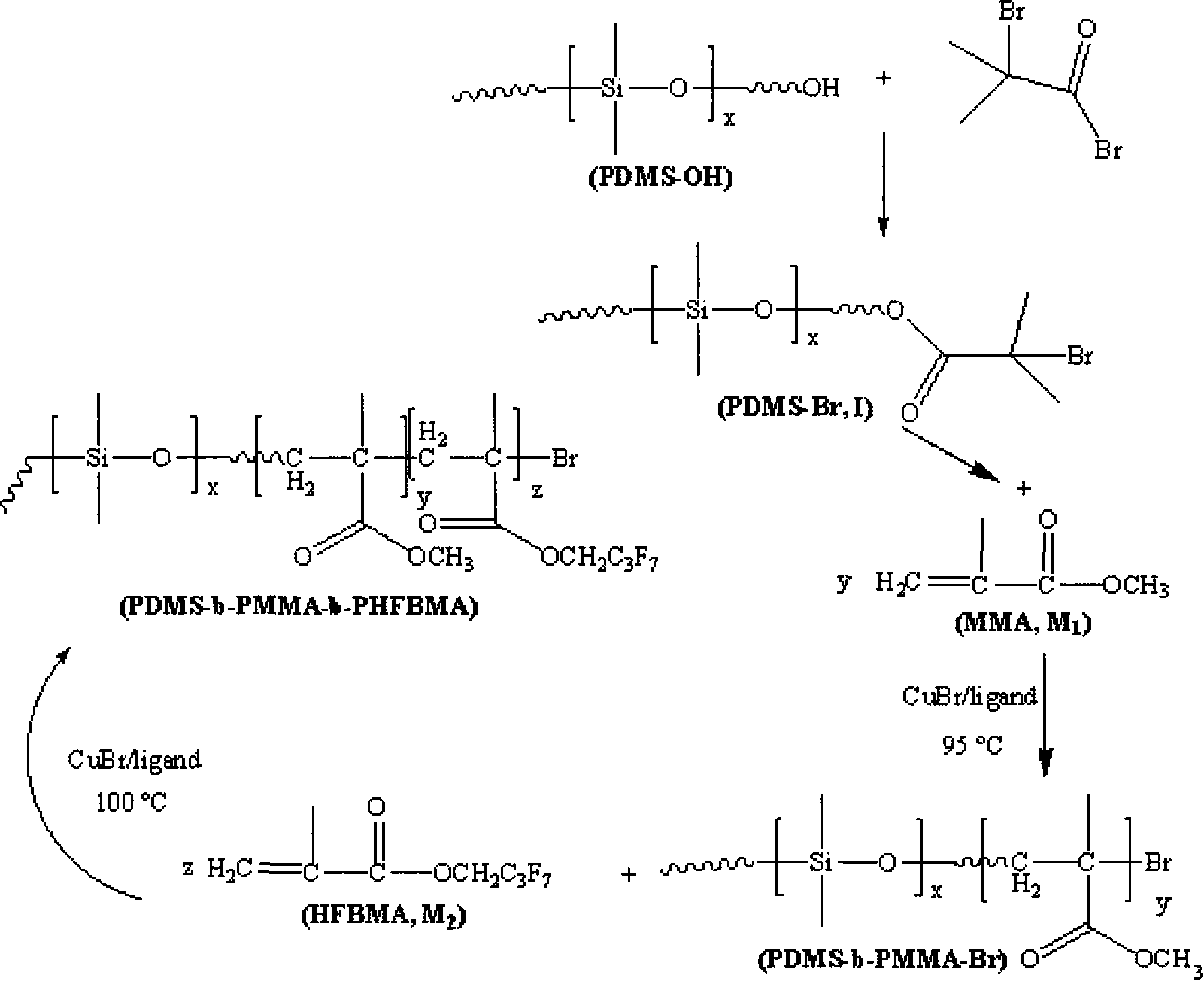

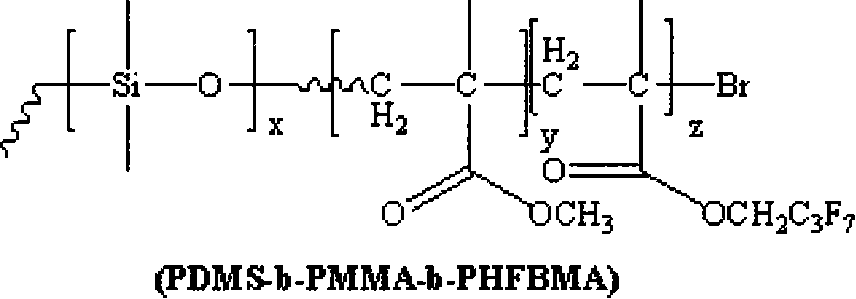

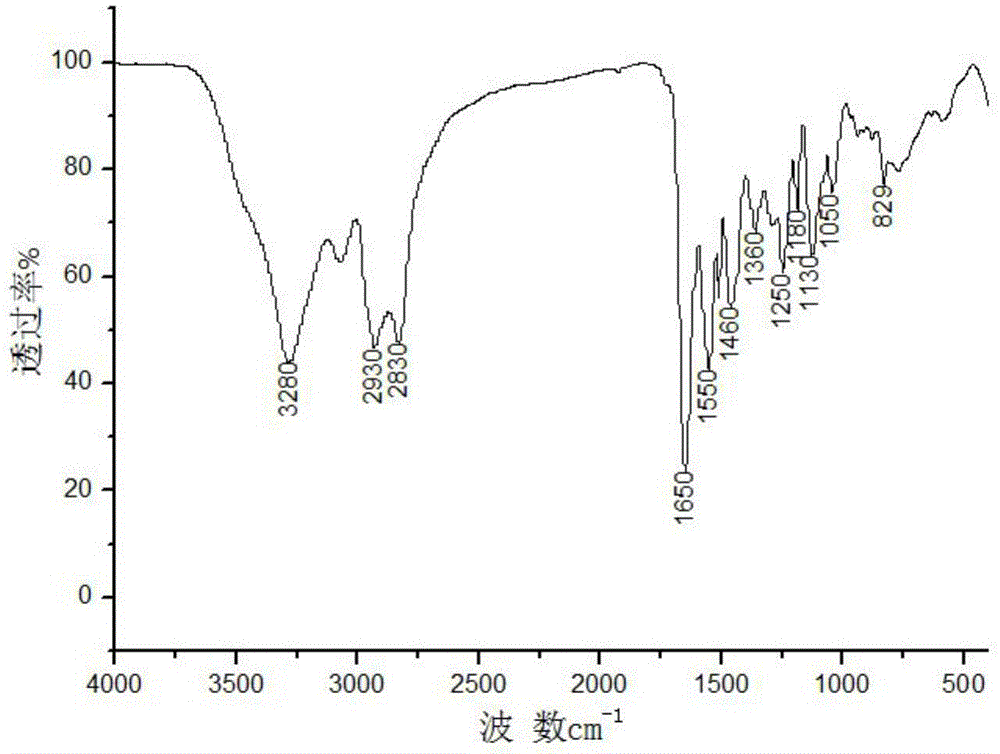

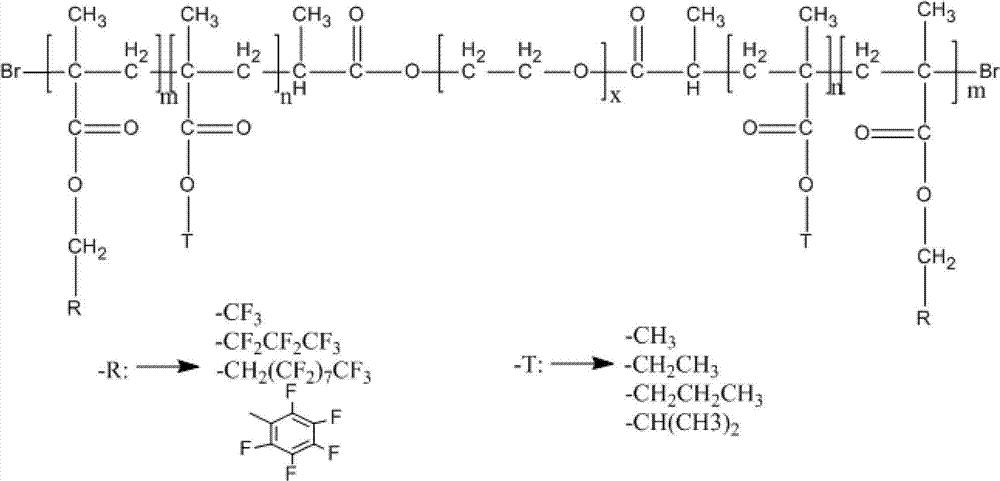

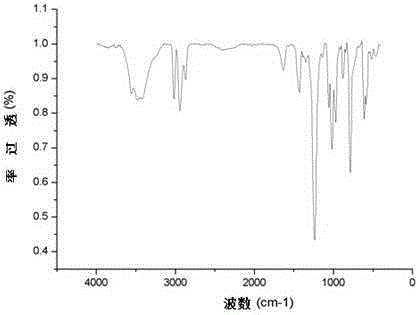

Fluorine silicon tri-block copolymers and preparation method thereof

The invention relates to a fluorine-silicon three-block copolymer and a process for preparation, which relates to the synthesis of fluorine low-surface three-block copolymer. The invention provides a fluorine-silicon three-block copolymer and a process for preparation, whose reaction condition is moderate, the structure of the reaction products is accurate, the original skeleton construction of each block is kept, the production has micro-phase separation structure, and the operation is simple and convenient. The invention is named as dimethyl silicone polymer-b-polymethyl methacryate-b-poly seven-fluorine butyl methacrylate ester, the process for preparation comprises first, preparing dimethyl silicone polymer macromolecule initiator of the sealing end of bromine atom, second, preparing two-block copolymer macromolecule initiator of the dimethyl silicone polymer-b-polymethyl methacryate, finally, preparing the fluorine-silicon three-block copolymer of the dimethyl silicone polymer-b-polymethyl methacryate-b-poly seven-fluorine butyl methacrylate ester.

Owner:XIAMEN UNIV

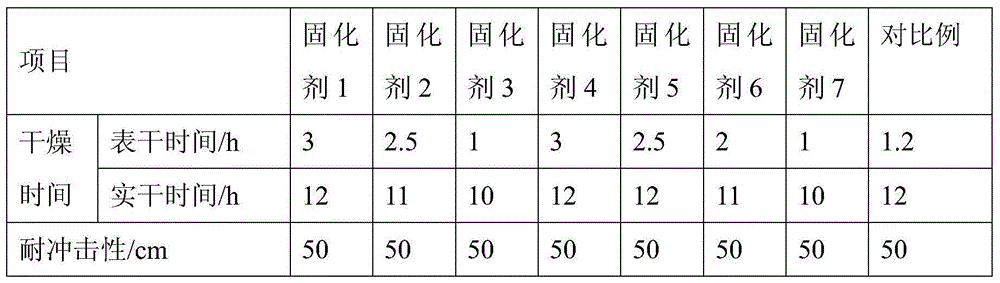

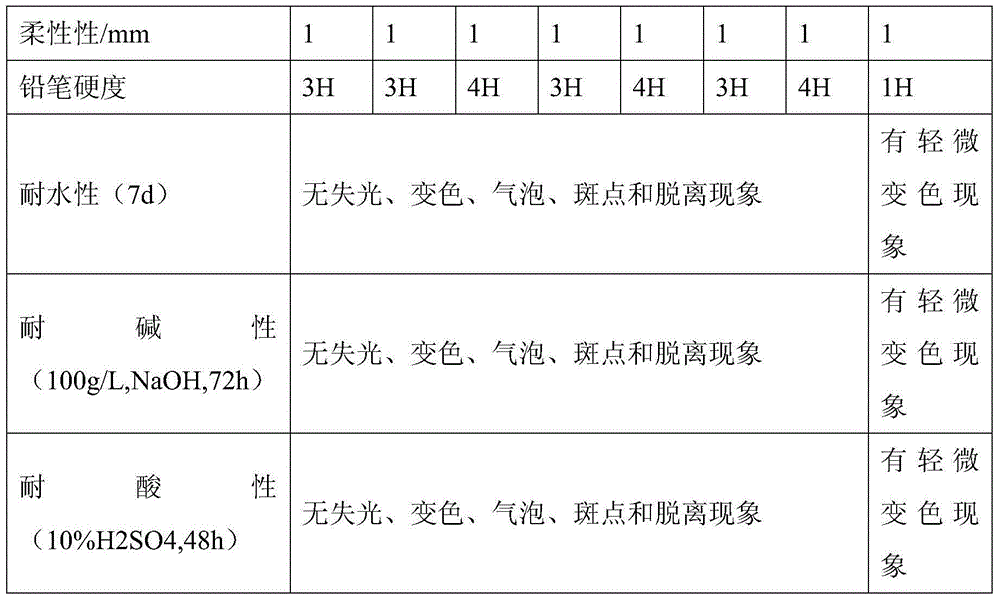

Preparation method of amide self-emulsifying water-borne epoxy resin curing agent

The invention provides a preparation method of an amide self-emulsifying water-borne epoxy resin curing agent. The preparation method comprises the steps of synthesis of an acylamino polyamine long chain, synthesis of a self-emulsifying water-borne epoxy resin curing agent and the like. The molecular structure of the amide self-emulsifying water-borne epoxy resin curing agent prepared through the preparation method contains both a hydrophilic acylamino polyamine long chain structure and an oleophilic bisphenol A resin structure, but does not contain polyether long chains or organic acids; the acylamino polyamine long chain structure enables a paint film to be good in the performances of flexibility, resistance to acid and base, and the like, and the water resistance of the paint film is improved and the application field of water-borne epoxy resin is widened since the polyether long chains and organic acids are not contained; moreover, the crosslinking density of the paint film is high, and the paint film is extremely high in pencil hardness by virtue of the polyamine structure.

Owner:JIANGSU SOBUTE NEW MATERIALS

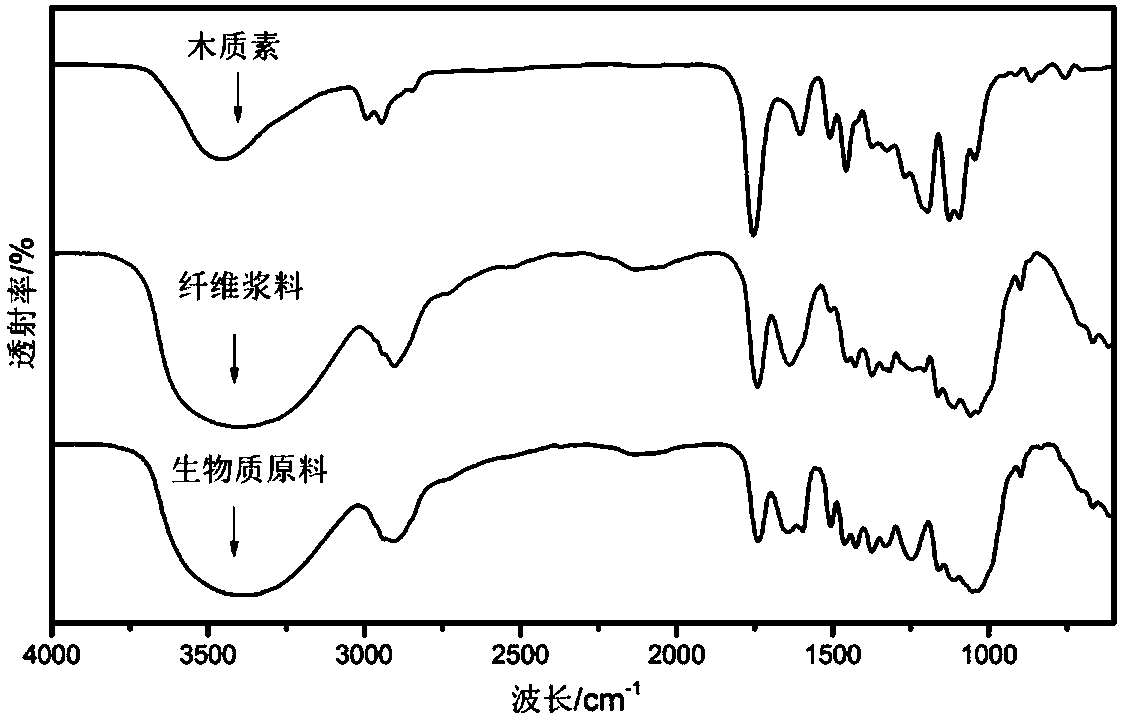

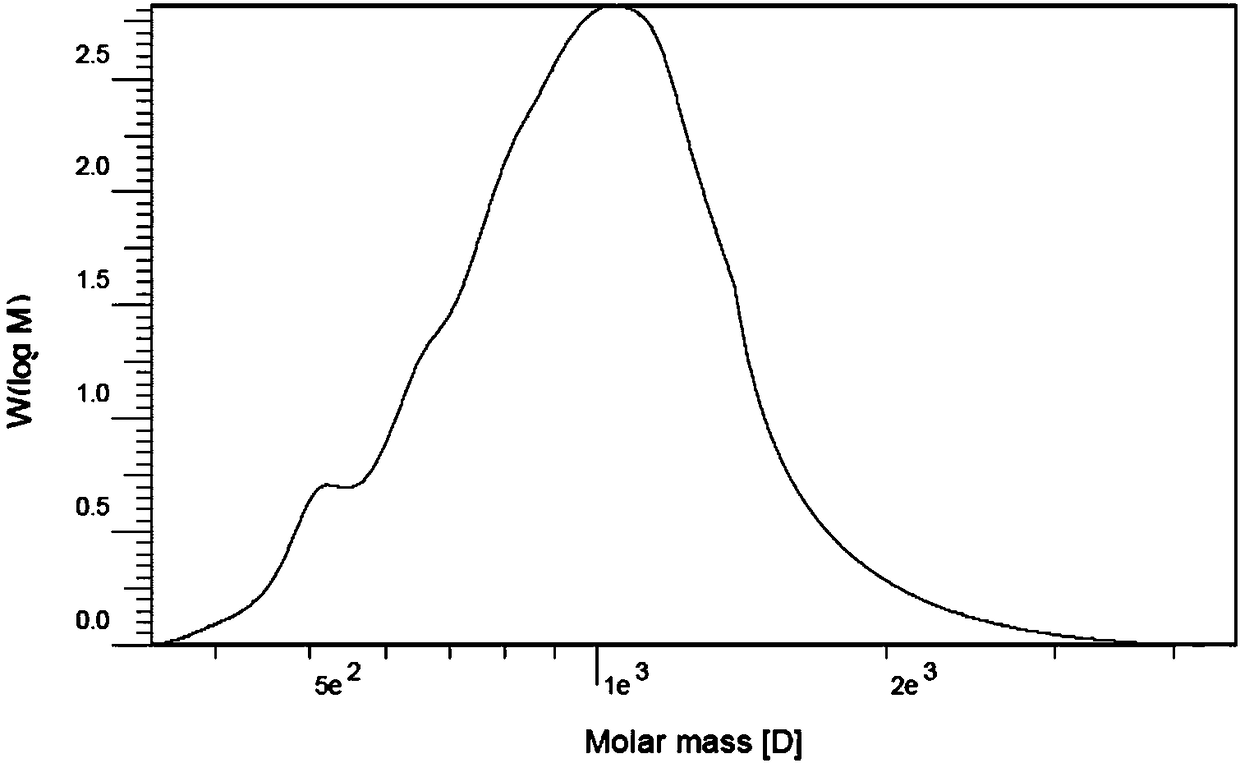

Method for extracting low-molecular-weight lignin from biomass

The invention relates to a method for extracting low-molecular-weight lignin from biomass. The preparation method comprises the following steps of (1) preparing an extraction agent: preparing cholinechloride and hydrogen bond donors into a mixed solution at a certain mol mass ratio; then, performing reaction under a certain condition to form a uniform solution, namely the extraction agent; (2) adding the extraction agent into the biomass raw materials; adding catalysts; performing reaction for a certain time under the stirring condition at a certain temperature; performing filtering; adding deionized water; performing precipitation and centrifugation to obtain solid substances; then, cleaning the solid substances by absolute ethyl alcohol and deionized water; performing drying; obtaininga finished product. According to the method, poplar, bamboo-willow, wheat straw and the like are used as the biomass raw materials; the solvent prepared at a specific proportion under the specific conditions is used as the extraction agent for extracting the low-molecular-weight lignin. The method has the advantages that the reaction conditions are mild; the process is simple; green effect and high efficiency are realized; the extraction cost is low; the method is suitable for large-scale production application.

Owner:QILU UNIV OF TECH

Bromol production method

ActiveCN101219935ASimple processMild reaction temperatureOrganic chemistryOrganic compound preparationSodium bicarbonateFiltration

The invention discloses a method for preparing a tribromophenol, which is characterized in that bromine is generated by the hydrogen peroxide reaction between a hydrogen bromide and an oxidant, and then the bromine continues to react with a phenol to synthesize a tribromophenol, and the method can be finished with no middle steps. A crude product passes through water, a sodium bicarbonate liquor and a sodium bisulfite liquor, then after the simple treatments of water washing, impurity removal and filtration, the product can be got. The method has the advantages of simple and convenient process, easy operation, high reaction safety, less pollution and simple post processing. The yield ratio can reach to more than 96 percent. The product has a high purity, is easy to realize industrial production and has a strong practicality.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

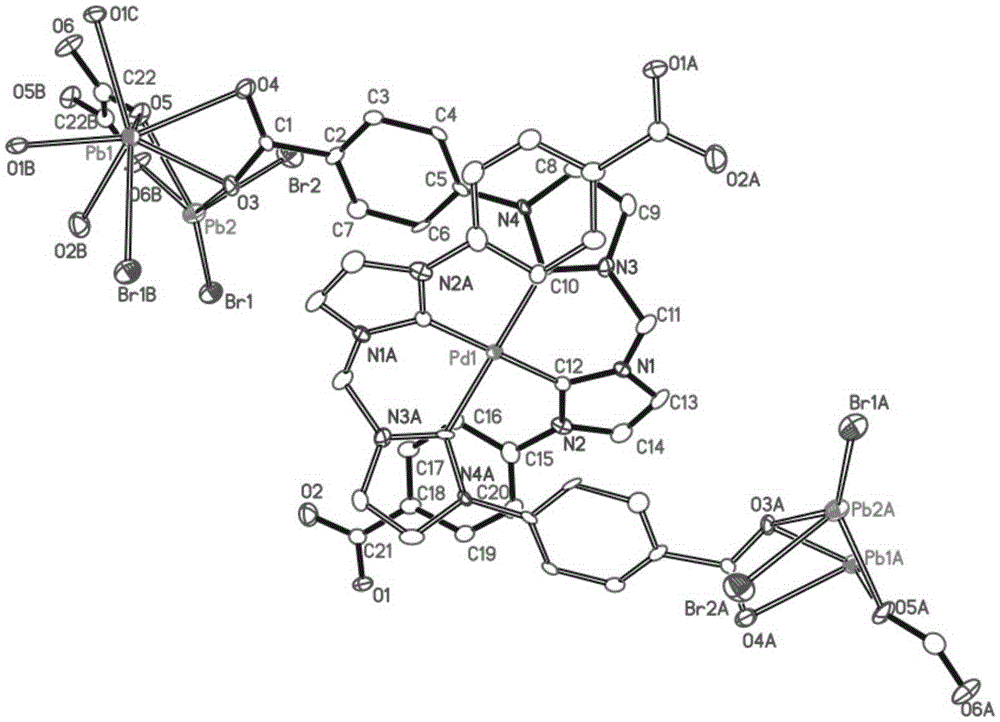

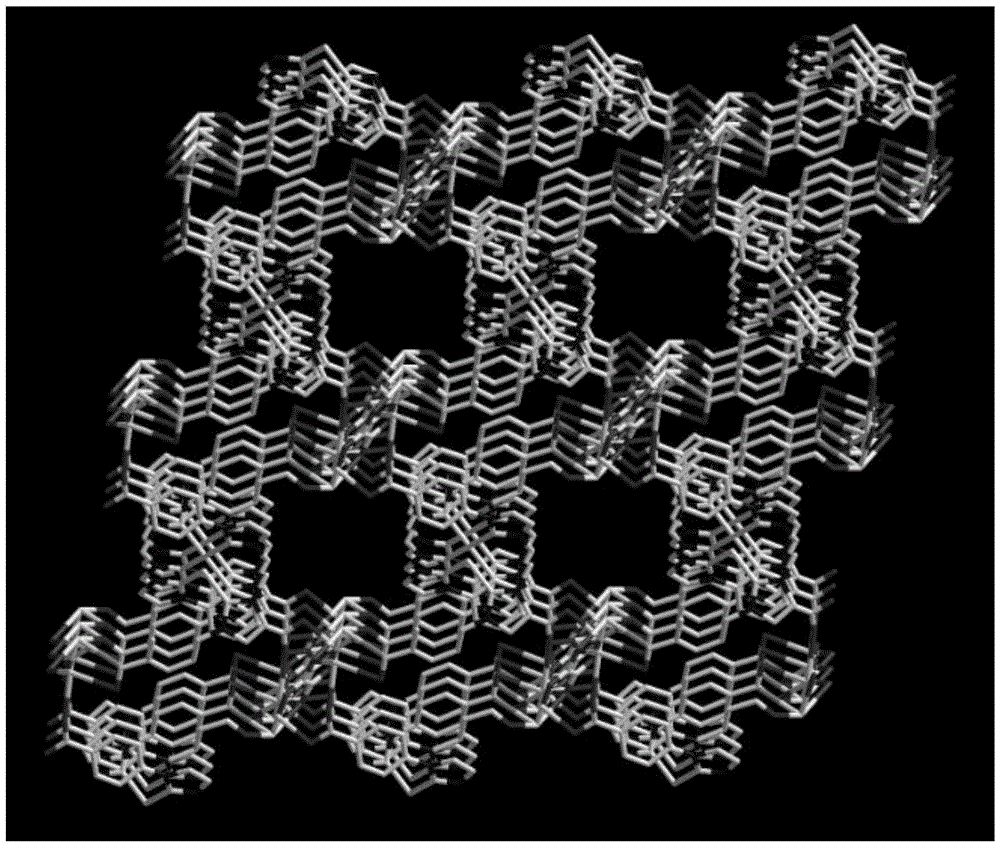

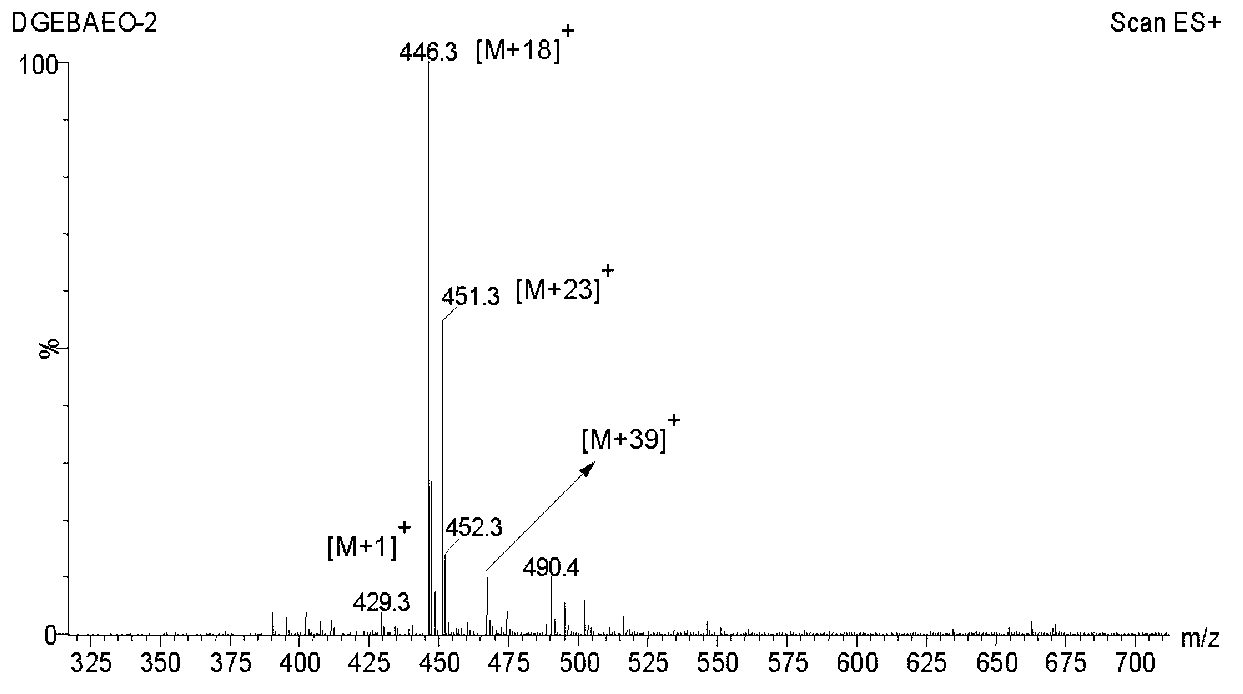

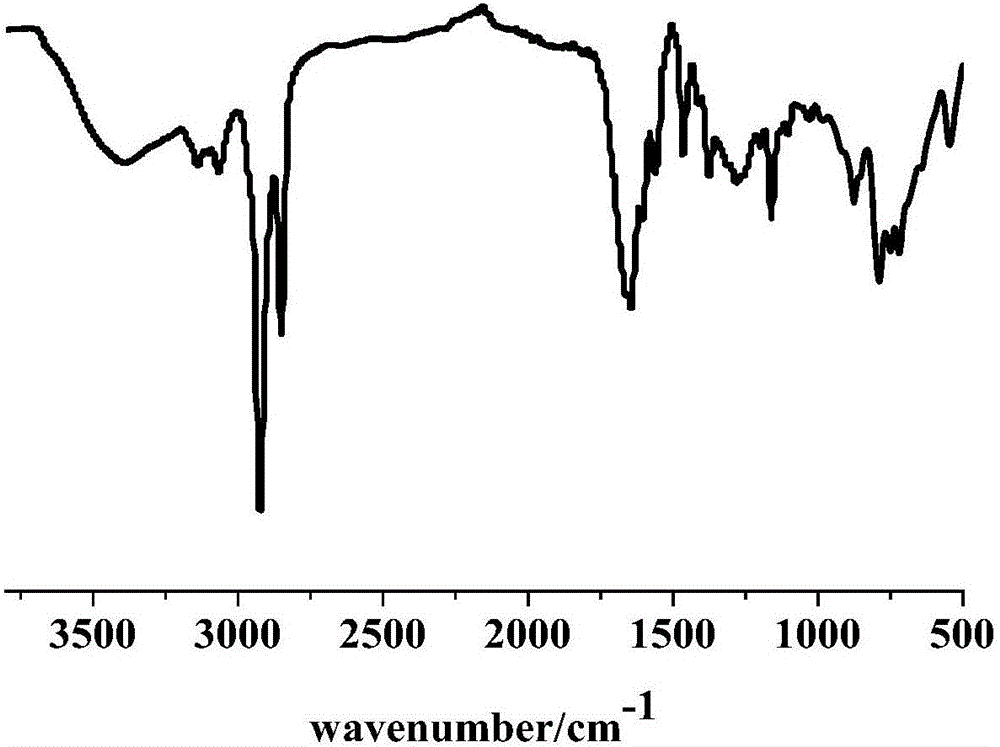

Organic ligand and Pd/Pb-based bi-metal organic framework as well as synthetic method and application thereof

InactiveCN105348327AHarm reductionPlay a catalytic roleOrganic-compounds/hydrides/coordination-complexes catalystsOrganic chemistry methodsHalohydrocarbonReactive site

The invention discloses an organic ligand and a Pd / Pb-based bi-metal organic framework as well as a synthetic method and application of the organic ligand and the Pd / Pb metal organic framework. A structural formula of the Pd / Pb-based bi-metal organic framework (Pd / Pb-MOF) is [Pb4(C42H28N8O8Pd)(C2O4)Br4]n, wherein n is a nonzero natural number. The Pd / Pb-based bi-metal organic framework (Pd / Pb-MOF) is used as a catalyst to be applied to catalyzing benzyne homocoupling and catalyzing three-component coupling reaction of benzyne, boracic acid and allyl halohydrocarbon. The MOF catalyst with active sites can be used for replacing some heavy metals to achieve a catalytic effect, so that the harm of the heavy metals to the environment is reduced. The MOF catalyst with the active sites is used for catalysis, so that heterocatalysis is realized; additionally, the bi-metal organic framework catalyst can be recycled for more than four times, and the catalyst is easy to recycle, so that the utilization rate of the catalyst is increased, and the cost is reduced.

Owner:SHANDONG NORMAL UNIV

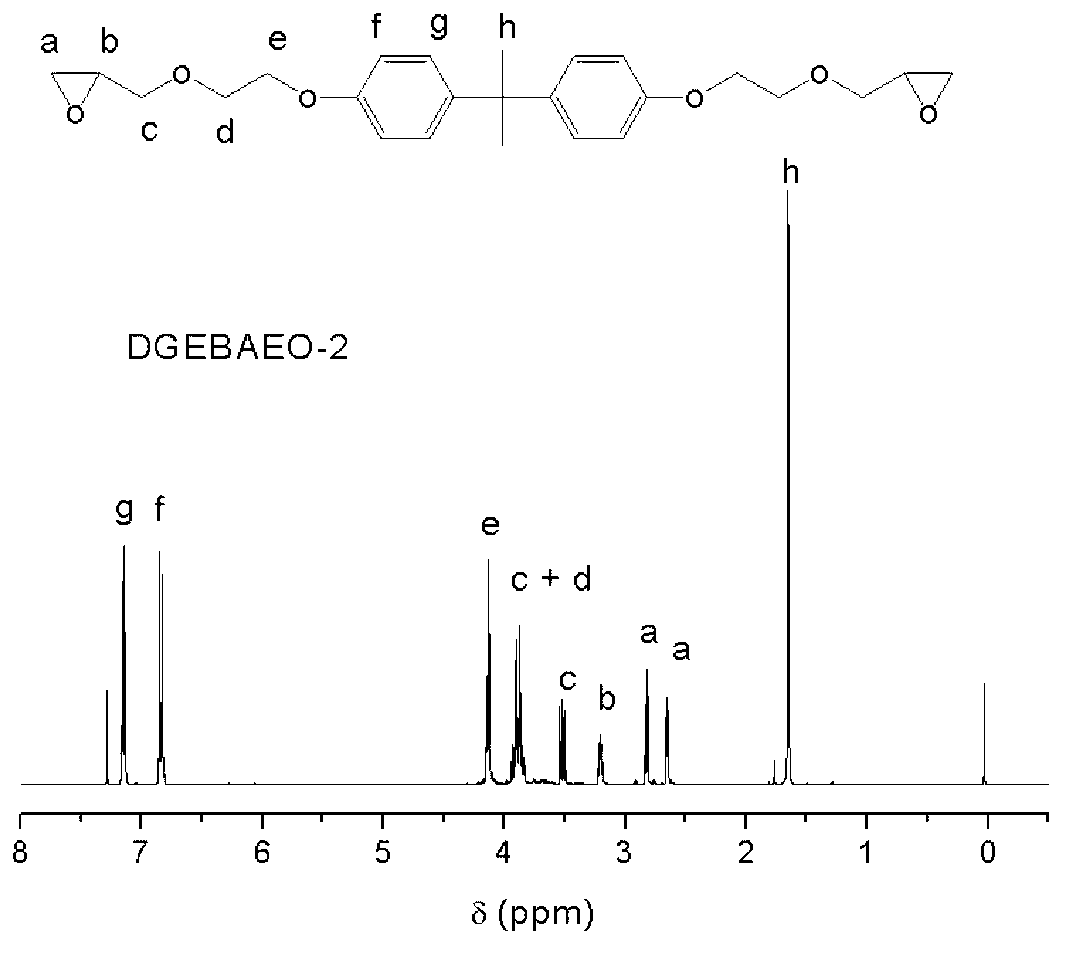

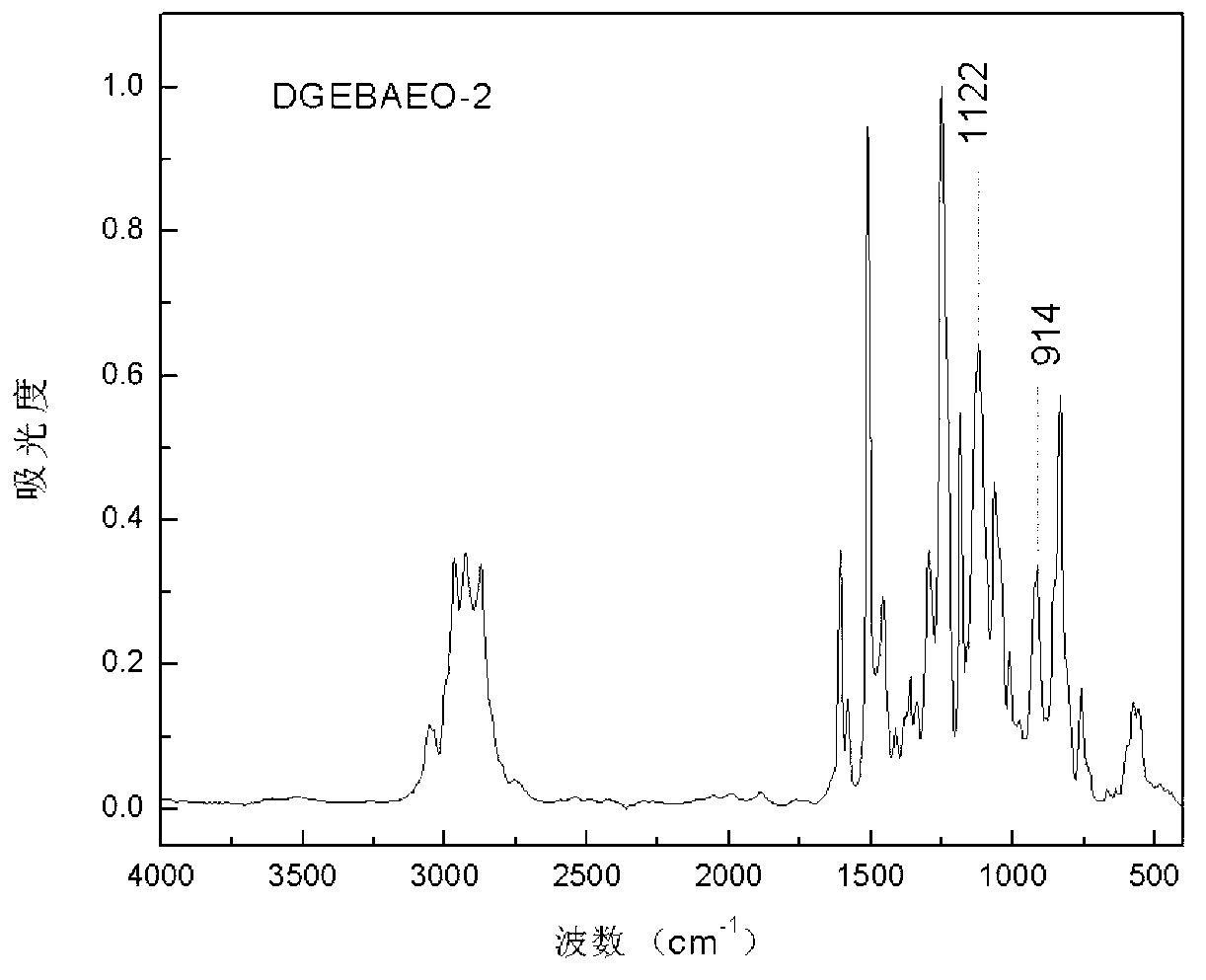

Method of preparing glycidyl ether epoxy resin through monomer containing alcoholic hydroxyl group and/or phenolic hydroxyl group

The invention discloses a method of preparing glycidyl ether epoxy resin through monomer containing alcoholic hydroxyl group and / or phenolic hydroxyl group, belonging to the technical field of epoxy resin. The method comprises the following steps of: adding the monomer containing alcoholic hydroxyl group and / or phenolic hydroxyl group and epoxy chloropropane into a reactor, and heating the reactor to fully dissolve the ingredients; controlling the reaction temperature to 40-80 DEG C, and adding a quaternary ammonium salt and solid alkali; pumping and filtering to remove the redundant alkali and the generated salt after the reaction is finished for 0.5-5 hours, adding an organic solvent immiscible to water while capable of dissolving the obtained epoxy resin to dilute the product, washing the product through deionized water for multiple times, separating out an organic phase, and decompression distilling. The method provided by the invention has the advantages of high reaction speed, high percent conversion and capable of simultaneously etherifying the alcoholic hydroxyl group and the phenolic hydroxyl group.

Owner:BEIJING UNIV OF CHEM TECH

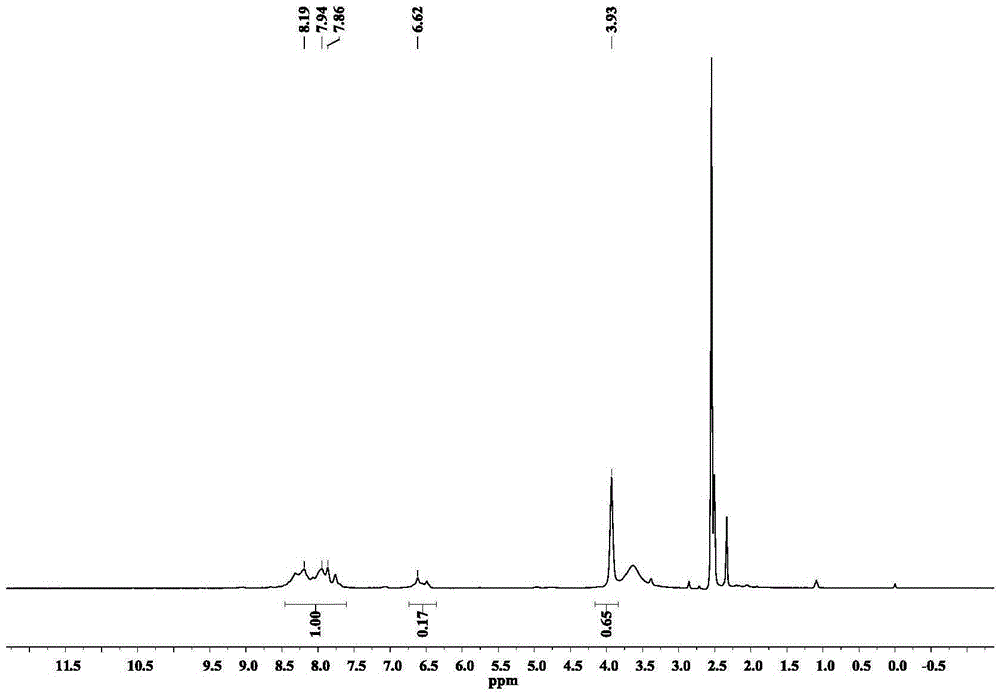

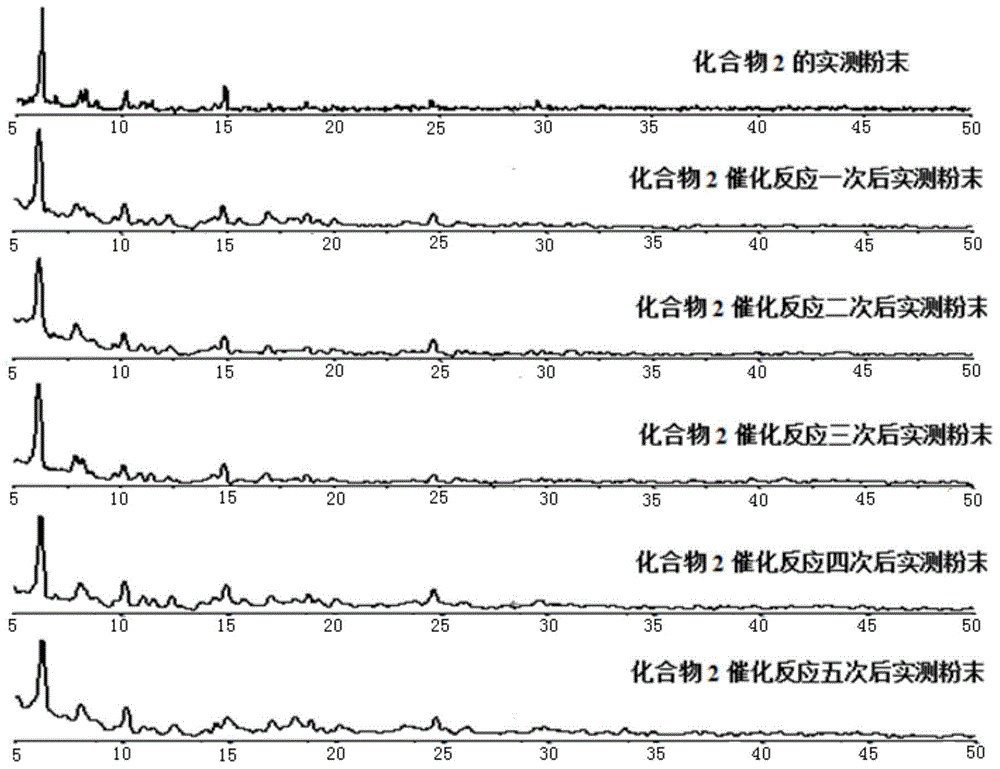

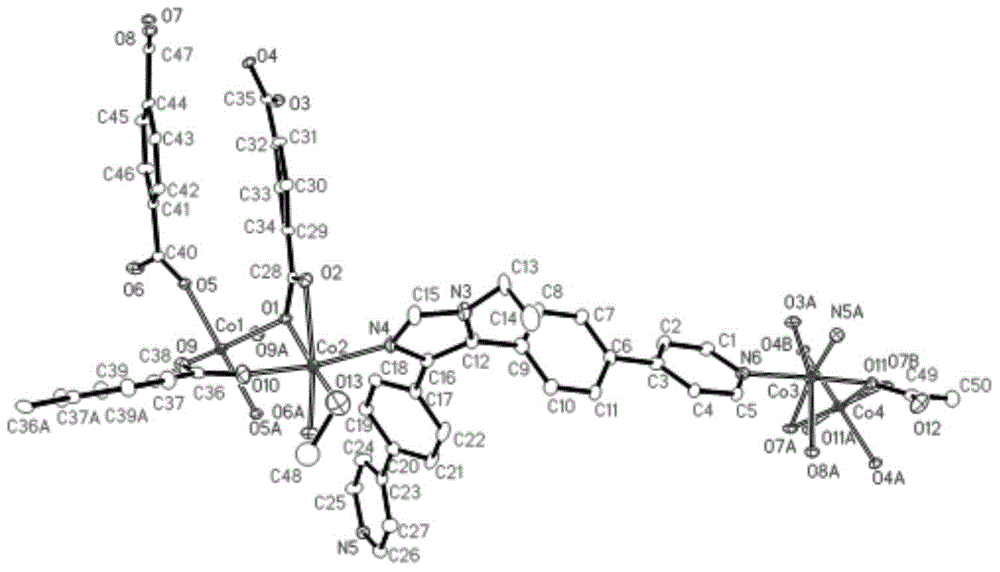

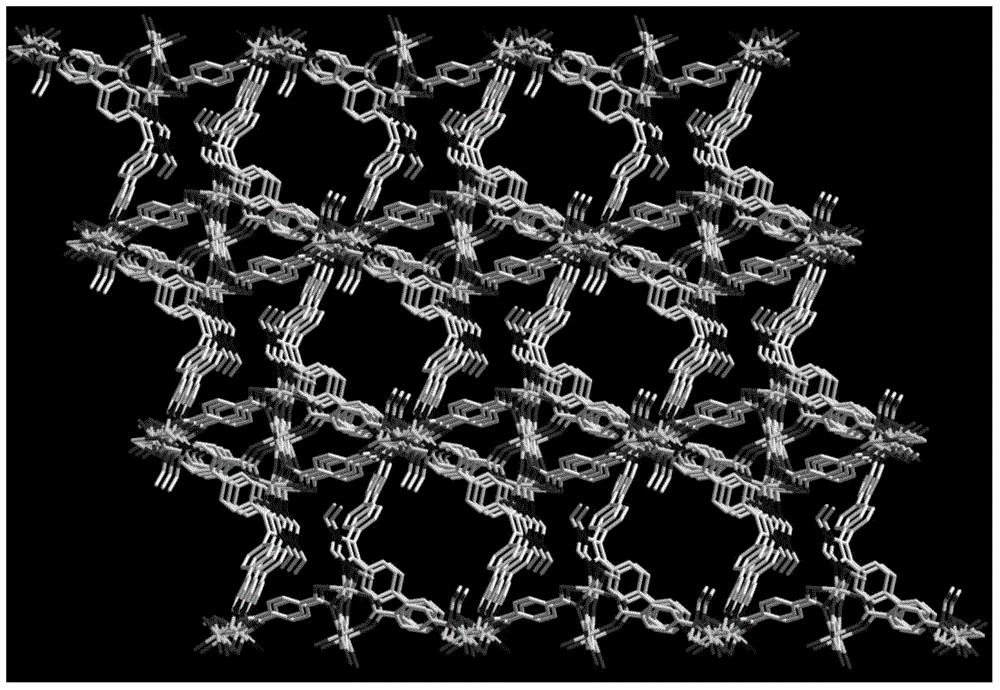

Co (II) based metal organic framework as well as preparation method and application thereof

InactiveCN104876971AHarm reductionEasy to recycleOrganic-compounds/hydrides/coordination-complexes catalystsCobalt organic compoundsReaction temperatureRoom temperature

The invention discloses an organic ligand L for synthesizing a Co (II) based metal organic framework, a Co (II) based metal organic framework Co-MOF-1 and a Co (II) based metal organic framework Co-MOF-2. The metal organic framework Co-MOF-1 is synthesized by virtue of the ligand L at first, and then crystals of the Co-MOF-1 are placed in the air for 24 hours at room temperature and then are subjected to constant-temperature treatment for 2 hours at 70 DEG C to obtain a novel catalyst Co-MOF-2 with active spots. The catalyst can be used for effectively catalyzing cyclohexane oxidation reaction, and a heavy metal is not needed to serve as a catalyst for reaction, so that the harm of the heavy metal to the environment is reduced, the reaction temperature is mild, the reaction time is relatively short, the usage amount of the catalyst is small, other additives are avoided, and the catalyst can be repeatedly used for more than 5 times relative to a free heavy metal salt.

Owner:SHANDONG NORMAL UNIV

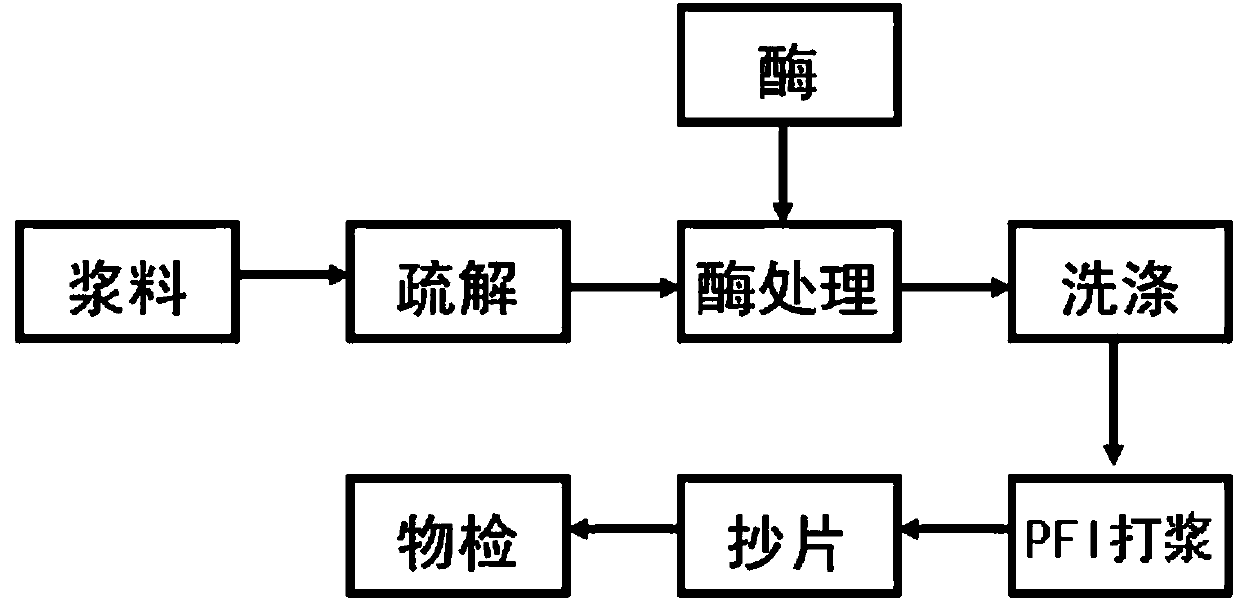

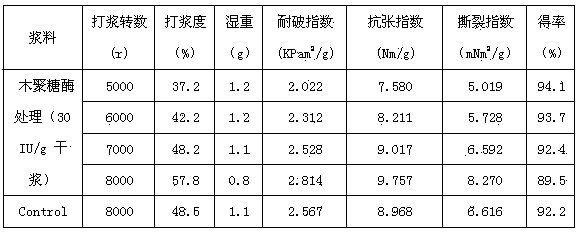

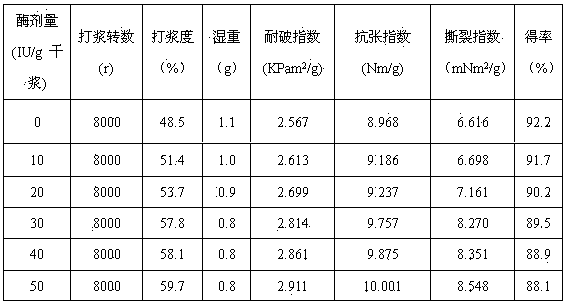

Enzymatic beating process for natural-color bagasse pulp

The invention discloses an enzymatic beating process for natural-color bagasse pulp. Xylanase is used in the enzymatic beating process for the natural-color bagasse pulp. The process comprises the steps of sizing agent defibering, enzyme treatment, washing, PFI beating, sheet making and physical detection. By adopting the process, the beating energy consumption of the natural-color bagasse pulp can be lowered effectively; the beating degree can be increased greatly up to 19.2 percent when enzyme treatment is performed on the xylanase at the dry pulp dosage of 30IU / g; meanwhile bagasse pulp cellulase can be protected from being damaged, and the process has important significance to the production of industrial paper from bagasse pulp.

Owner:GUANGXI UNIV

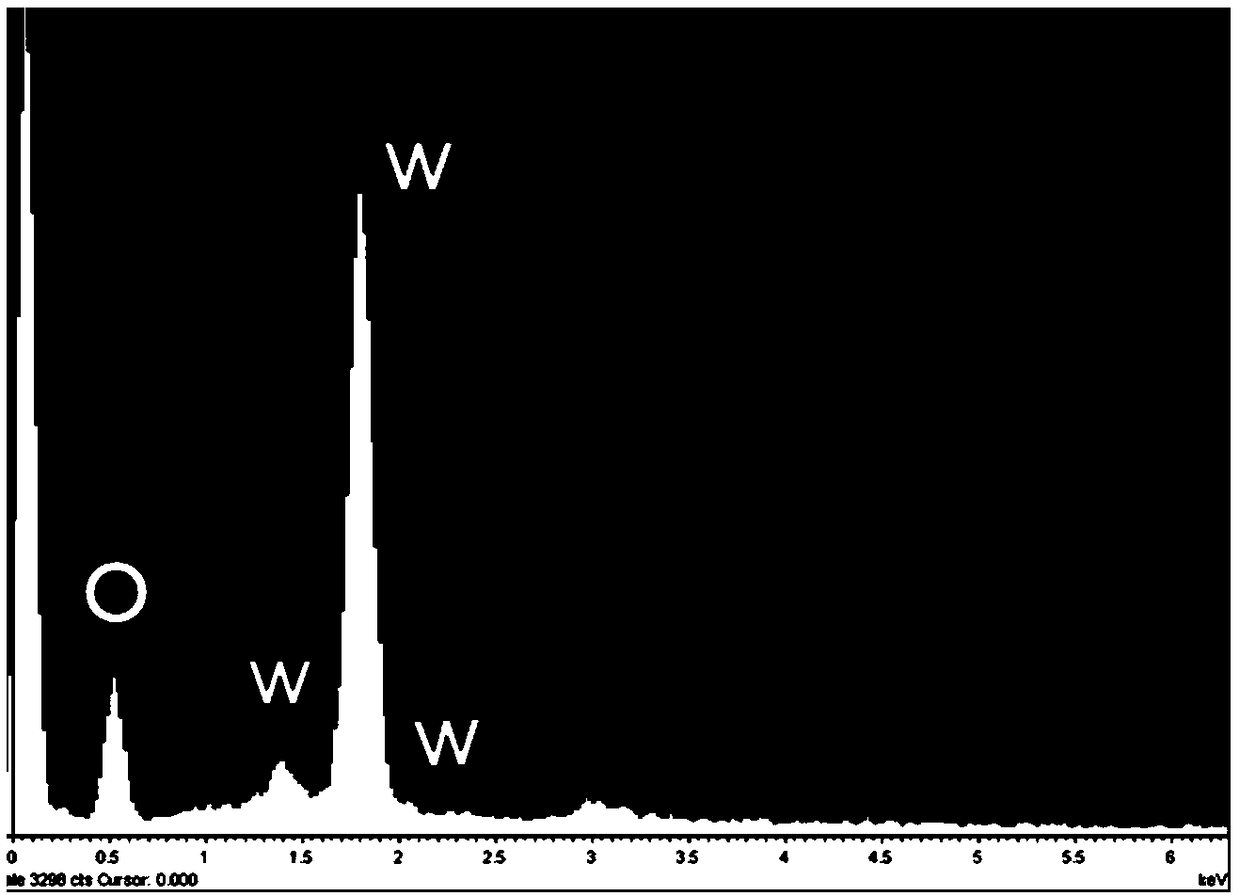

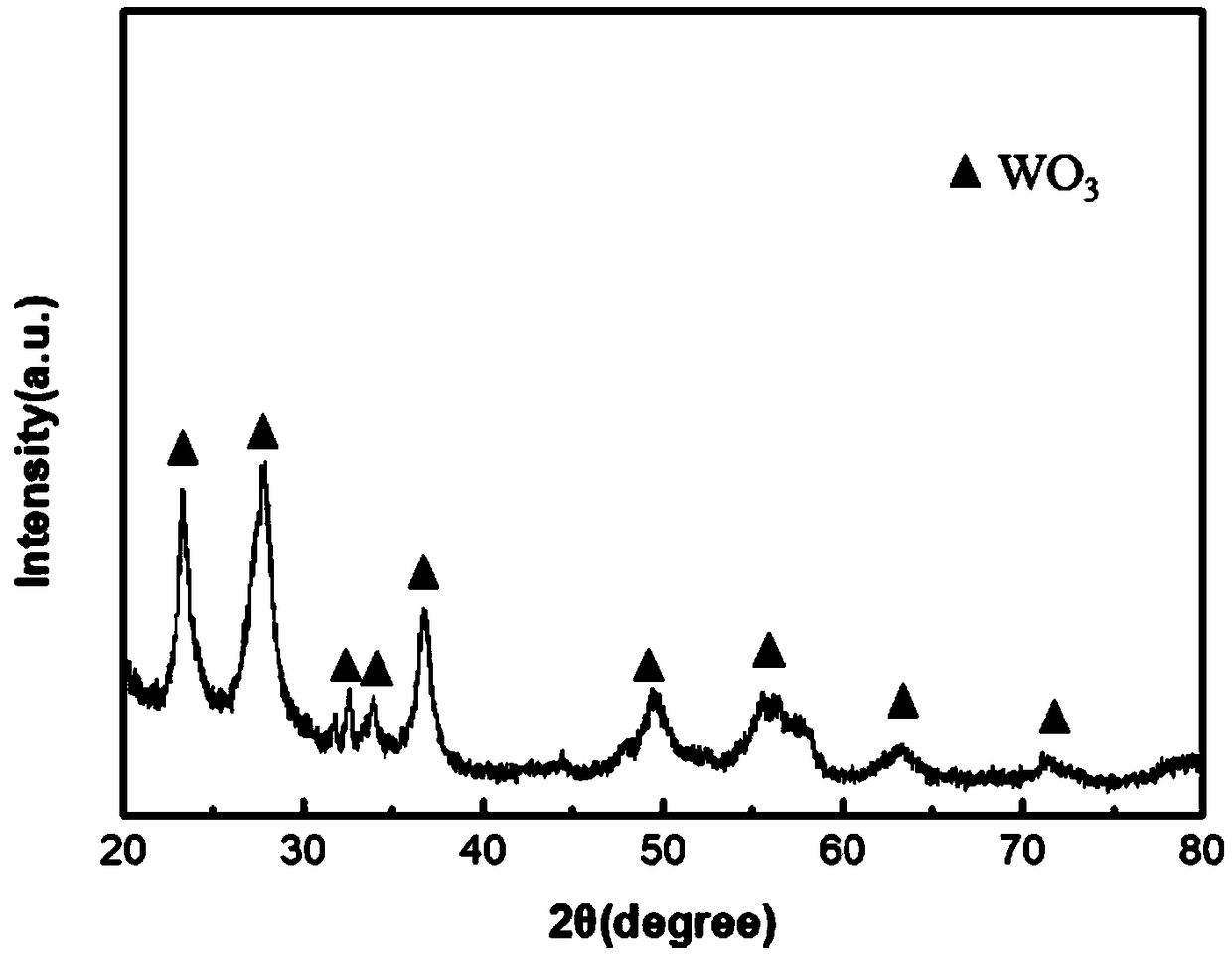

Flexible electrochromic film based on tungsten oxide, and preparation method and application of flexible electrochromic film

InactiveCN109240014AOvercome brittle shortcomings such as inflexibilityStable electrochromic performanceNon-linear opticsReaction temperaturePore diameter

The invention discloses a flexible electrochromic film based on tungsten oxide, and a preparation method and an application of the flexible electrochromic film. The flexible electrochromic film is made from amorphous tungsten oxide, has a loose and porous nano-morphology, and has the thickness of 200-400nm and the average pore diameter of about 100-300nm. The flexible electrochromic film has a loose and porous structure, so that the permeation and contact of an electrolyte are facilitated, and a path of charge transfer is shortened; and therefore, the flexible electrochromic film is good in electrochromic performance and wide in optical modulation range. The flexible electrochromic film based on the tungsten oxide has the characteristics of being flexible and bendable; and the flexible electrochromic film still has the electrochromic performance when being bent for more than 90 degrees. The preparation method is simple in preparation process, mild in reaction temperature and low in cost; and a possible preparation method is provided for industrial production of the tungsten oxide-based flexible electrochromic film.

Owner:NANJING UNIV OF POSTS & TELECOMM

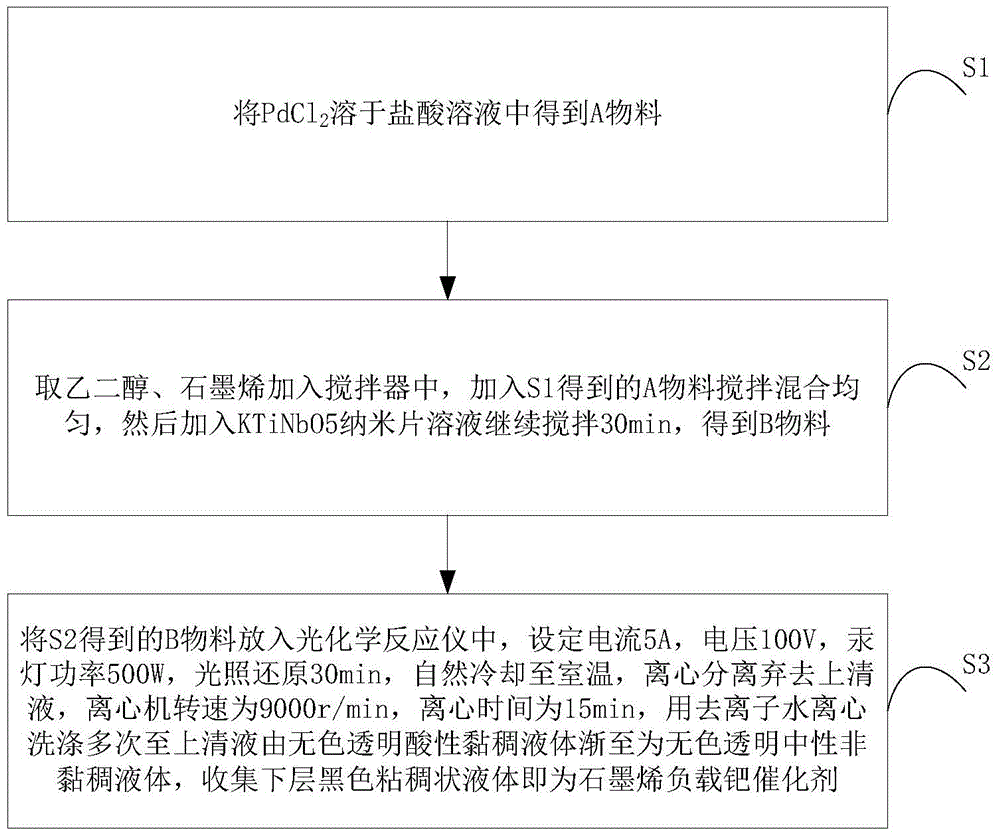

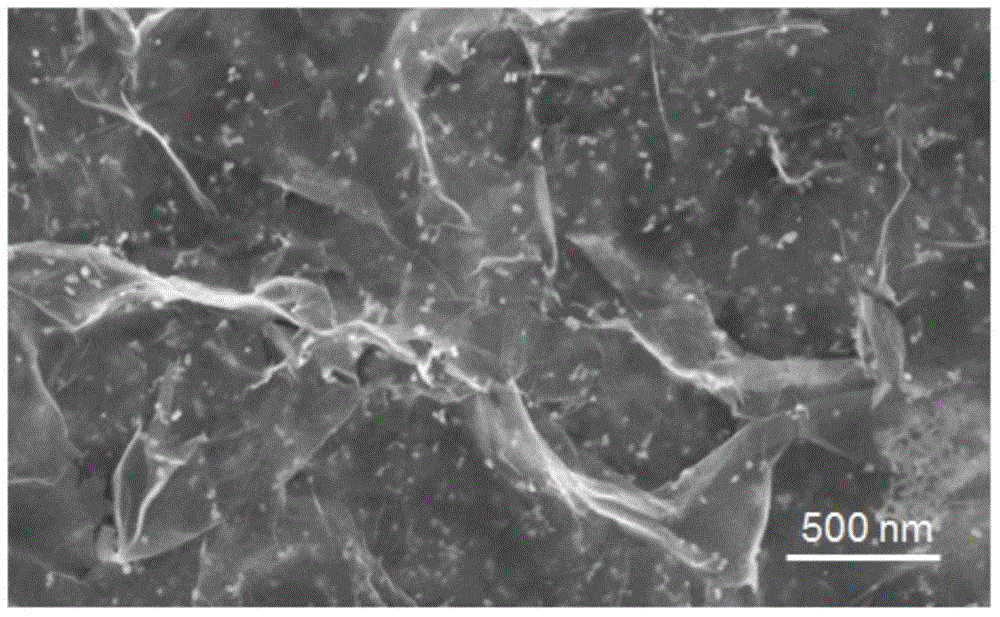

Graphene-supported palladium catalyst, preparation method and application thereof

ActiveCN105126830ASmall dispersionGood dispersionOrganic compound preparationChemical recyclingAfter treatmentPalladium catalyst

The invention discloses a graphene-supported palladium catalyst, which includes following raw materials, by volume, 2-10 parts of a material A, 30-50 parts of ethylene glycol, 100-150 parts of graphene and 5-20 parts of a KTiNbO5 nano sheet solution, wherein the material A includes the raw materials of PdCl2 and hydrochloric acid being 30-37% in concentration, wherein the weight / volume ratio of the PdCl2 to the hydrochloric acid is (0.01-0.1) g : (10-40) ml. The invention also provides the preparation method and an application of the graphene-supported palladium catalyst. In the invention, a conventional method of the graphene-supported palladium catalyst is replaced by the preparation method, which is free of surfactants, is small in particle size, is simple in operation, can be used in synthesis of cinnamic acid, is high in yield of cinnamic acid, is simple in separation and after-treatment, is mild in reaction conditions and is green and economical.

Owner:ANHUI UNIV OF SCI & TECH

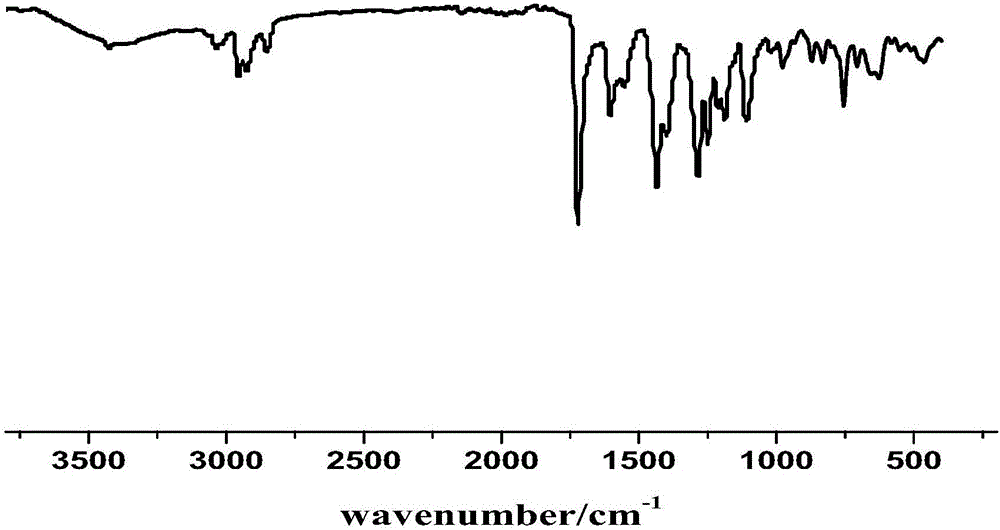

Triphase catalyst UiO-67-IM and preparation method and application thereof

ActiveCN106432087AHarm reductionEasy to recycleOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidMetal-organic framework

The invention discloses an organic ligand L for synthesizing a triphase catalyst UiO-67-IM and the triphase catalyst UiO-67-IM. The triphase catalyst UiO-67-IM has the structural formula of [Zr6O4(OH)4L6]n, wherein n is a nonzero natural number. A preparation method of the triphase catalyst UiO-67-IM comprises the steps that the organic ligand L, ZrCl4 and acetic acid are dissolved into DMF, heat preservation is conducted for 24 hours at 120 DEG C, the temperature is lowered to room temperature, and then the metal organic framework UiO-67-IM is obtained. The catalyst can effectively catalyze a benzyl chloride azidation reaction, heavy metal salt does not need to serve as the catalyst, heterogeneous catalysis is achieved, the catalyst can be repeatedly utilized 5 times or above and is easy to recycle, the utilization rate of the catalyst is increased, and the cost is reduced; meanwhile, the catalyst is mild in reaction temperature, short in reaction time, low in dosage, free of other additives and beneficial for industrialized application and popularization.

Owner:SHANDONG NORMAL UNIV

Synthesis method of organosilicone modified superfine aluminum hypophosphite

InactiveCN105860594AImprove mechanical propertiesLower surface potential energyPigment treatment with organosilicon compoundsCooking & bakingSynthesis methods

The invention discloses a method for synthesizing organosilicon-modified ultrafine aluminum hypophosphite, which comprises the following steps: 1) preparing sodium hypophosphite aqueous solution; 2) preparing aluminum sulfate aqueous solution; 3) preparing organosilicon-modified ultrafine aluminum hypophosphite : First add a dispersant to the sodium hypophosphite solution, then slowly add the aluminum sulfate aqueous solution to the sodium hypophosphite solution dropwise, and continue to stir for 0 to 3 hours; After stirring for 0-1h, cool to room temperature, wash and test the filtrate with a certain concentration of barium chloride solution, and wait for no white precipitate to appear in the filtrate, then place it in an oven for drying to obtain organosilicon-modified ultrafine aluminum hypophosphite product . The present invention uses organic silicon as a modifier to make organic silicon modified aluminum hypophosphite and high molecular compound more tightly combined, improve the interfacial binding force between the flame retardant and high molecular material, the reaction conditions are mild, and the yield is high , which is more suitable for industrialization.

Owner:SHIFANG TAIFENG NEW FLAME RETARDANT

Production method foaming rubber sole

The invention discloses a production method of a foaming rubber sole. The method comprises the steps of: a. weighing the following raw materials by weight: natural rubber, reclaimed rubber, sulfur, activated zinc oxide, engine oil, vulcanization accelerator, vulcanizing agent, phenolic resin and a foaming agent; b. adding the raw materials including the natural rubber, the reclaimed rubber, the phenolic resin, the activated zinc oxide and the engine oil into an internal mixer, then adding the foaming agent into the sizing, continuously mixing, and discharging; c. adding the internally mixed material into an open mill, adding sulfur, the vulcanizing agent and the vulcanization accelerator for vulcanization, standing for 12-24 hours after the sizing mixing, adding the milled sizing into the open mill for hot mixing, and processing the sizing to be of the vulcanization-needed shape. The production method has the advantages that the natural rubber and the reclaimed rubber are mixed in the internal mixer, the mixed material is transferred into the open mill, and sulfur, the vulcanizing agent and the vulcanization agent are added for vulcanization; the reaction temperature is mild, and the reaction time is short; and the sole produced by the method is wear-resistant, aging-resistant and light in weight.

Owner:JIANGSU BOJIETE MINE MACHINERY

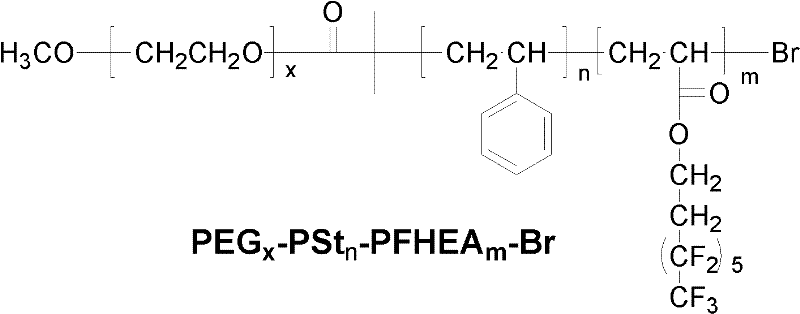

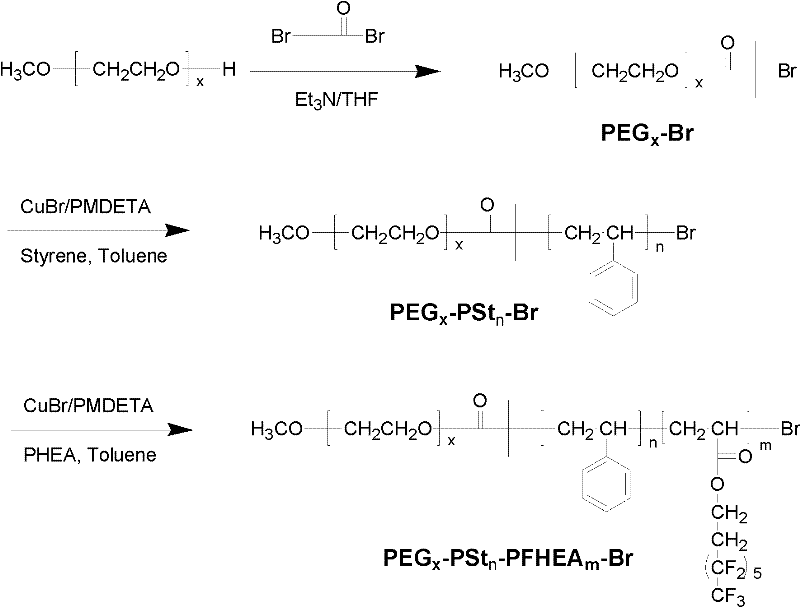

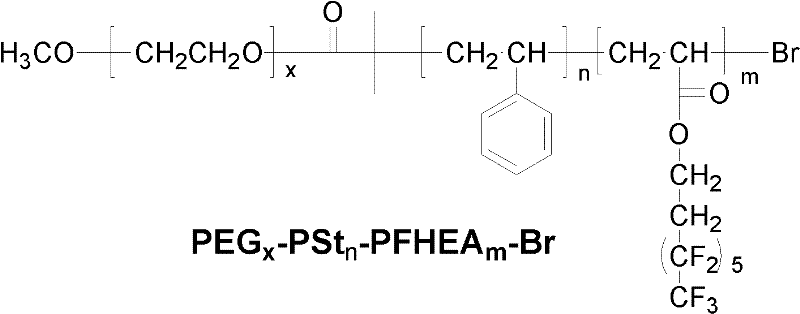

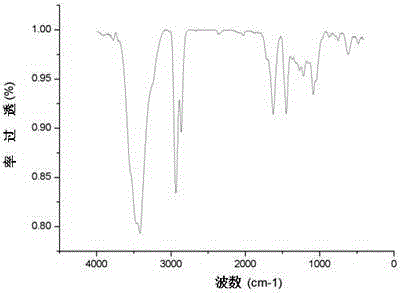

Polyethylene glycol (PEG)-b-polystyrene (PSt)-b-perfluorohexylethyl acrylate (PFHEA) and preparation method thereof

The invention discloses PEG-b-PSt-b-PFHEA. The PEG-b-PSt-b-PFHEA is prepared by treating bromine-terminated PEG as a macroinitiator, obtaining a PEG-b-PSt diblock copolymer through an atom transfer radical polymerization reaction, and treating the diblock copolymer as the macroinitiator to initiate PFHEA monomer polymerization. The preparation method has the advantages of mild reaction conditions, economy, simple operation and high product yield. The product of the present invention has a clearer structure and a narrower molecular weight distribution than products prepared by common radical polymerization reactions, and has a microphase separation structure, and low interfacial energy and surface energy which allow protein adsorption to be inhibited.

Owner:SHANDONG JIAOTONG UNIV

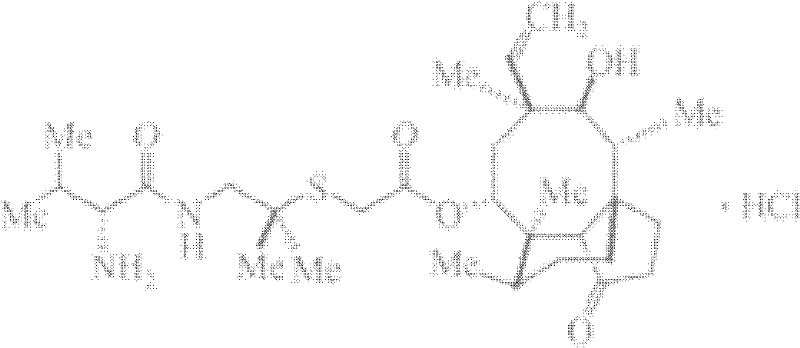

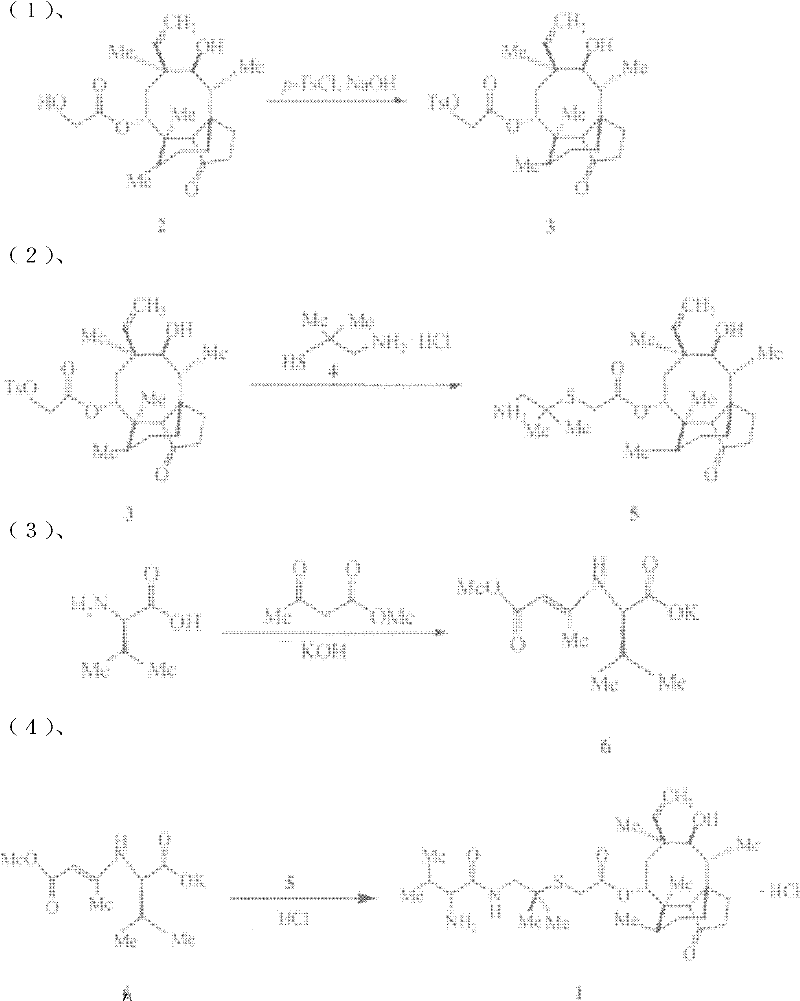

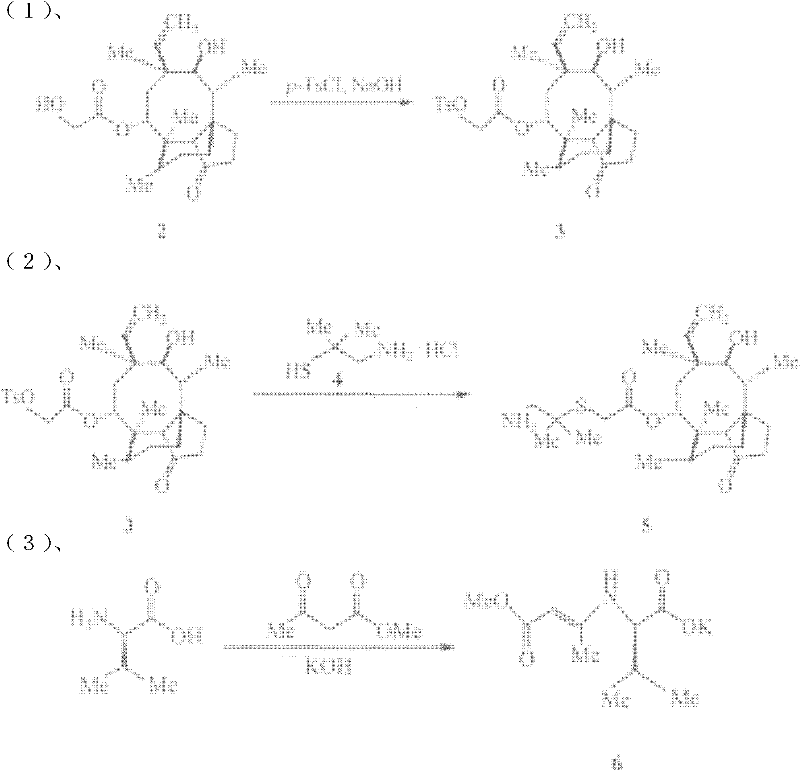

Preparation method of valnemulin hydrochloride

InactiveCN102225905AReduce pollutionMild reaction temperatureSulfide preparationReaction temperatureSolvent

The invention relates to a preparation method of valnemulin hydrochloride. The preparation method comprises the following steps: reacting pleuromutilin with p-toluenesulfonyl chloride, substituting with 1-amino-2-methyl propyl-2-mercaptan hydrochloride so as to obtain [(2-amino-1,1-dimethyl S, 6S, 8R,9R, 9aR, 10R)-6-vinyl decahydro-5-hydroxyl-4,6,9,10-tertamethyl-1-oxo-3a, 9-propanol-3aH-cyclopentacyclooctene-8-yl ester for later use; reacting D-valine with methyl acetoacetate; synthesizing the product with isobutyl chloroacetate so as to generate anhydride; and reacting anhydride with [(2-amino-1,1-dimethyl ethyl) sulfenyl] acetic acid (3aS, 4R, 5, 6S, 8R,9R, 9aR, 10R)-6-vinyl decahydro-5-hydroxyl-4,6,9,10-tertamethyl-1-oxo-3a, 9-propanol-3aH-cyclopentacyclooctene-8-yl ester so as to generate amide, and then carrying out deprotection with hydrochloric acid so as to prepare valnemulin hydrochloride. The method has the advantages that (1) reaction temperature is mild, thereby being applicable to large-scale production; (2) post-treatment is simple, thereby directly obtaining the product; (3) used solvents are less, thereby reducing environmental pollution; and (4) the valnemulin hydrochloride content and yield of the obtained product are high.

Owner:HUBEI SHENZHOU CHEM

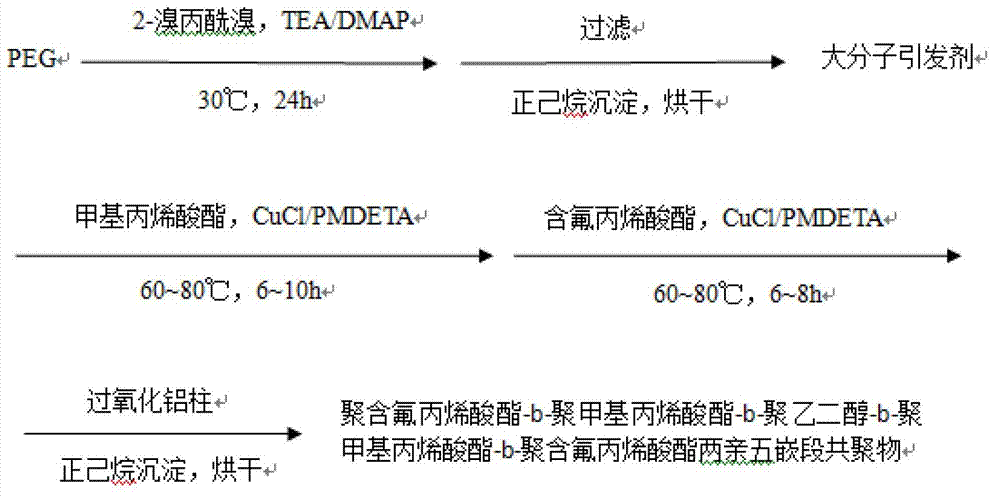

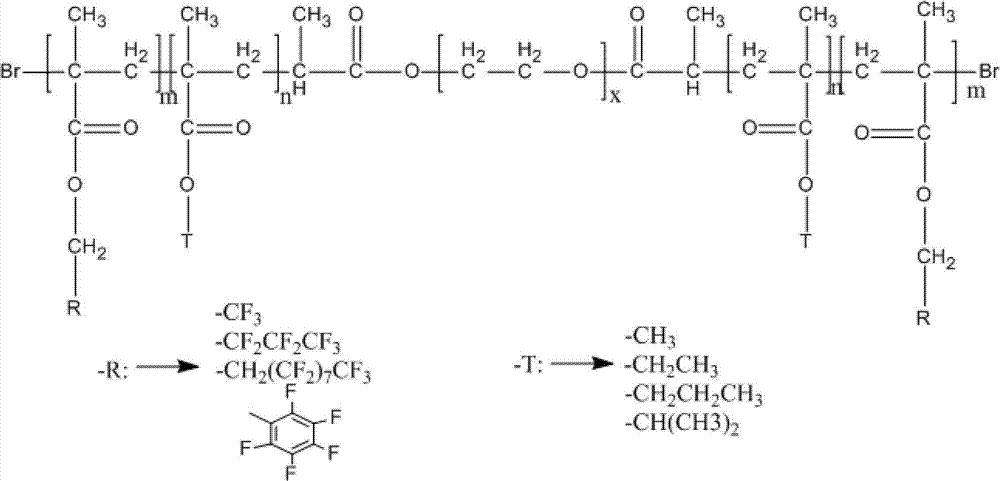

Amphiphilic fluorinated acrylate penta-block copolymer and preparation method thereof

The invention relates to an amphiphilic fluorinated acrylate penta-block copolymer and a preparation method thereof. The technical characteristics are that a name is amphiphilic fluorinated acrylate penta-block copolymer, namely poly-fluorinated acrylate-b-polymethacrylate-b-polyethylene glycol-b-polymethacrylate-b-poly-fluorinated acrylate. A synthetic method uses a bromine-terminated polyethylene glycol as a macro-molecule initiator and uses a one-pan way to gradually charge, that is performs an atom transfer radical polymerization reaction of the macro-molecule initiator with methacrylate, and after the reaction ends, directly adds the fluorinated acrylate to obtain the amphiphilic fluorinated acrylate penta-block copolymer through the atom transfer radical polymerization reaction. The copolymer and the preparation method have advantages of mild reaction condition, simple operation, reduced steps, high product yield, reduced cost, clear product structure and narrow molecular weight distribution, can save time and raw materials, and has potential application in fields of LCD, aerospace coating, photoconductive material, nano-carbon material, pharmaceutical carriers, etc.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

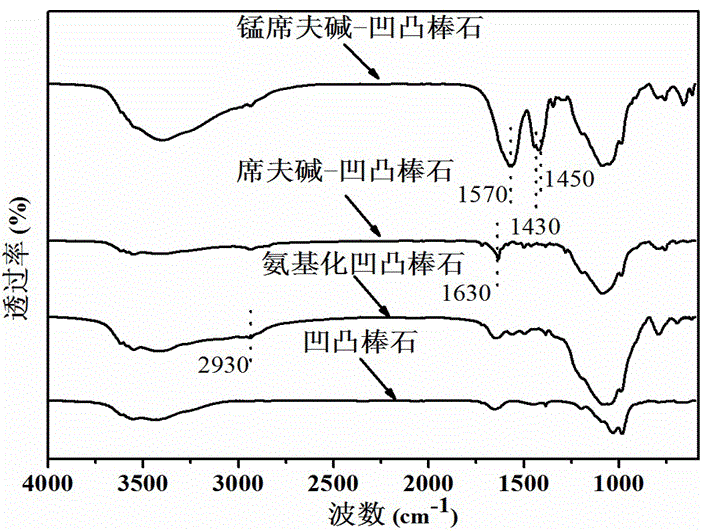

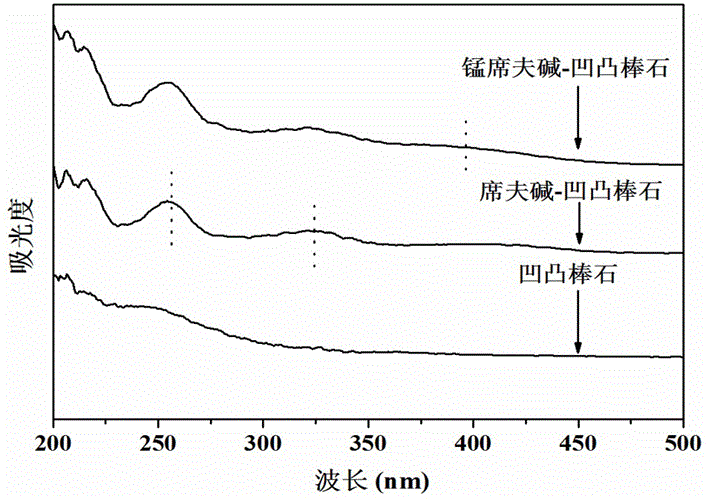

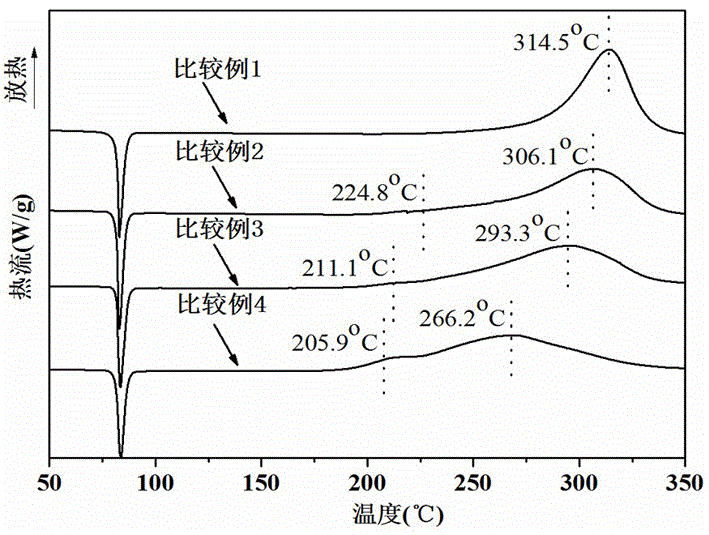

Modified attapulgite and preparing method thereof

ActiveCN104877394AGood dispersionPrevent crack growthPigment treatment with non-polymer organic compoundsPolymer scienceSalicylaldehyde

The invention discloses modified attapulgite and a preparing method thereof. The modified attapulgite is composed of attapulgite and manganese Schiff base. The preparing method of the modified attapulgite includes the steps that the attapulgite and hydrochloric acid are reacted to obtain acidulated attapulgite, and then the acidulated attapulgite is reacted with methylbenzene and gamma-aminopropyltriethoxysilane to obtain amination attapulgite; the amination attapulgite is added into mixed liquid composed of salicylaldehyde and ethyl alcohol for reaction to obtain attapulgite with Schiff base grafted to the surface; then the attapulgite is mixed with manganous acetate tetrahydrate, backflow, stirring and reacting are carried out in the N2 atmosphere, and the modified attapulgite is obtained after suction filtering, washing and drying are carried out. By means of the modified attapulgite, cyanate ester resin can be remarkably catalyzed and toughened at the same time, and the heat resistance of the resin is improved. The preparing method of the modified attapulgite has the advantages of being simple in technology, easy to control, wide in raw material source, low in cost and the like.

Owner:SUZHOU UNIV

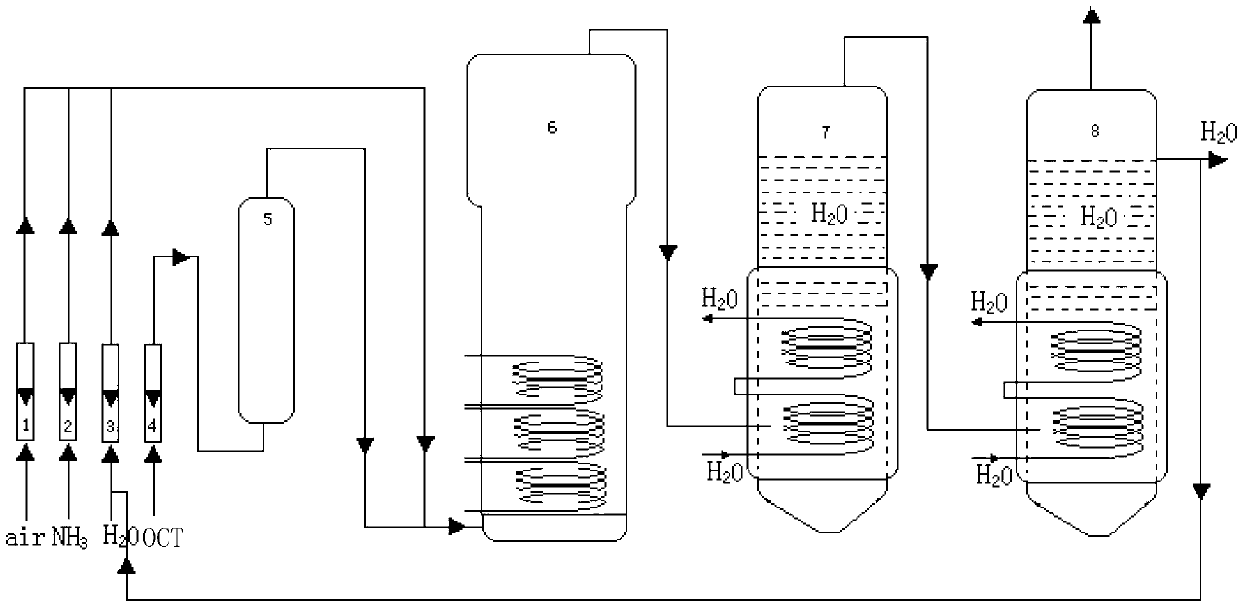

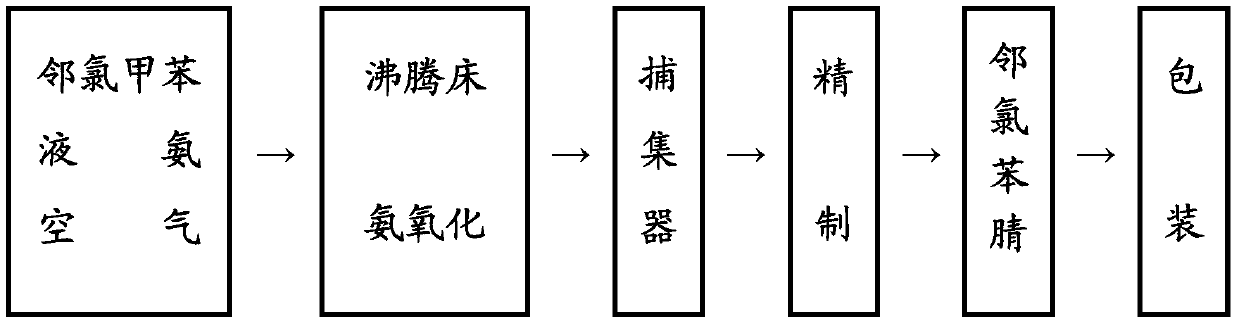

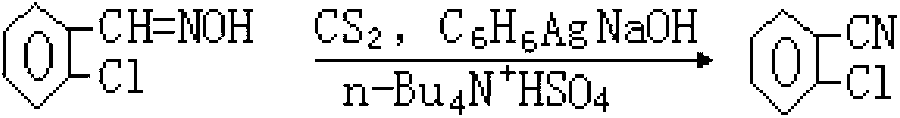

Production process for preparing chlorobenzonitrile through ammoxidation

InactiveCN103102287AMild reaction temperatureSolution to short lifePhysical/chemical process catalystsPreparation by hydrocarbon ammoxidationWater vaporFluidized bed

The invention provides a production process for preparing chlorobenzonitrile through ammoxidation. The production process comprises the following steps of: portioning air, ammonia, water vapor and o-chlorotoluene together; gasifying the o-chlorotoluene and then mixing the gasified o-chlorotoluene with air, ammonia and water vapor, and conveying the mixture to a fluidized bed reactor for reaction under the action of a catalyst; and after the reaction, cooling and crystallizing the generated product through a cold trap, thereby obtaining crude chlorobenzonitrile, wherein the catalyst is VaPbCecSbdOx multi-component catalyst, and wherein a=1, b=0.7-2, c=0.3-1, d=0.5-1, and the value of x is determined according to valence state balance when V, P, Ce and Sb are +5 valent, +5 valent, +4 valent, +5 valent and -2 valent, respectively. The production process provided by the invention employs the VaPbCecSbdOx as the active catalyst; and the catalyst is simple to fabricate, mild in reaction temperature, long in catalyst service life, high in activity, high in selectivity and the like; as a result, side reaction in the production process is suppressed, the production process of chlorobenzonitrile is improved and the yield of product is obviously improved.

Owner:HUBEI JUNTAI PHARMA CHEM

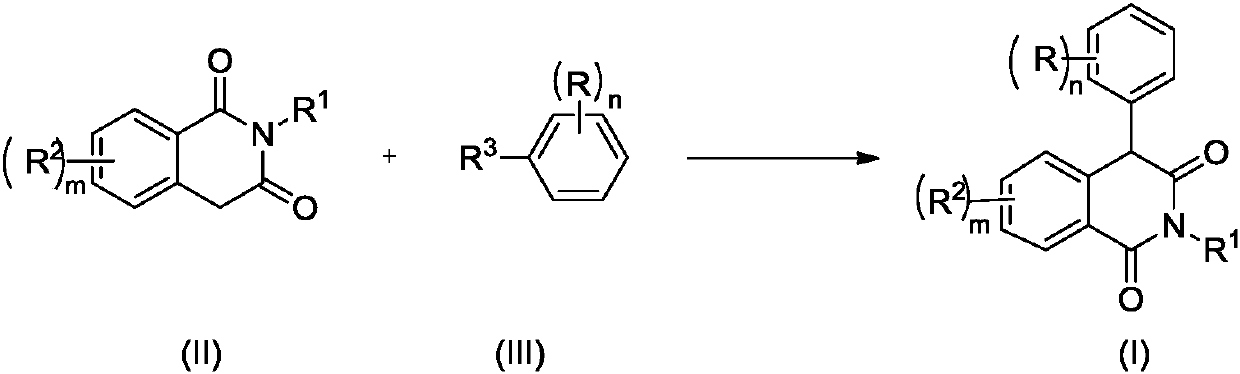

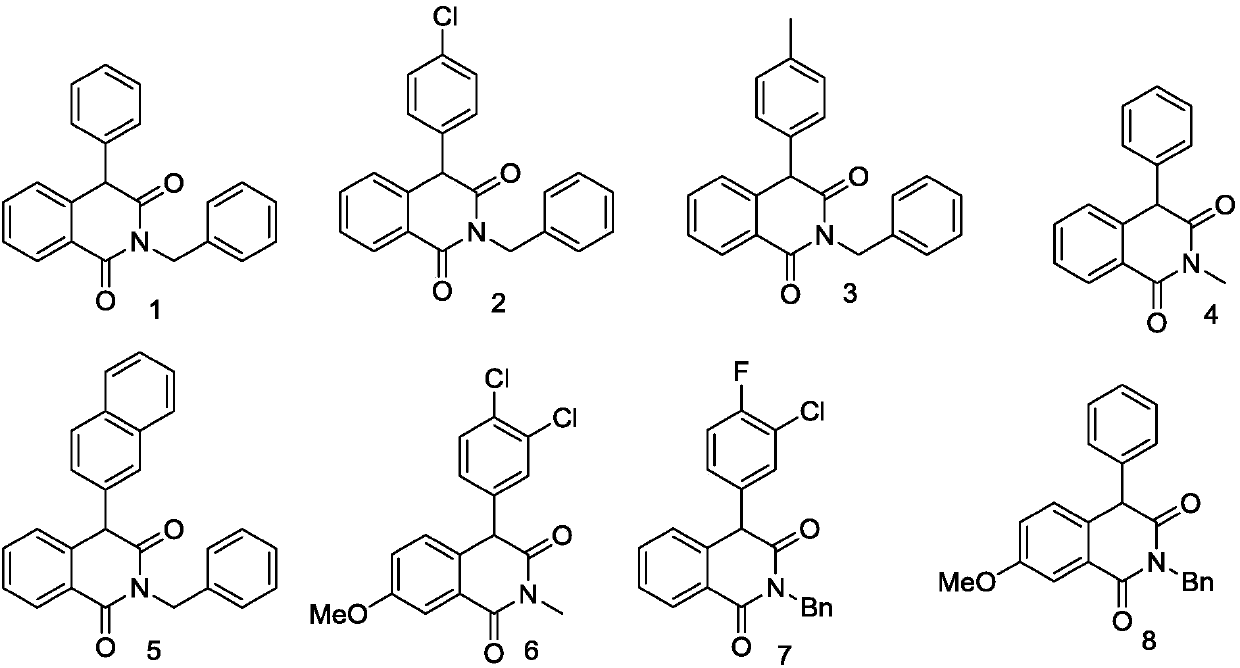

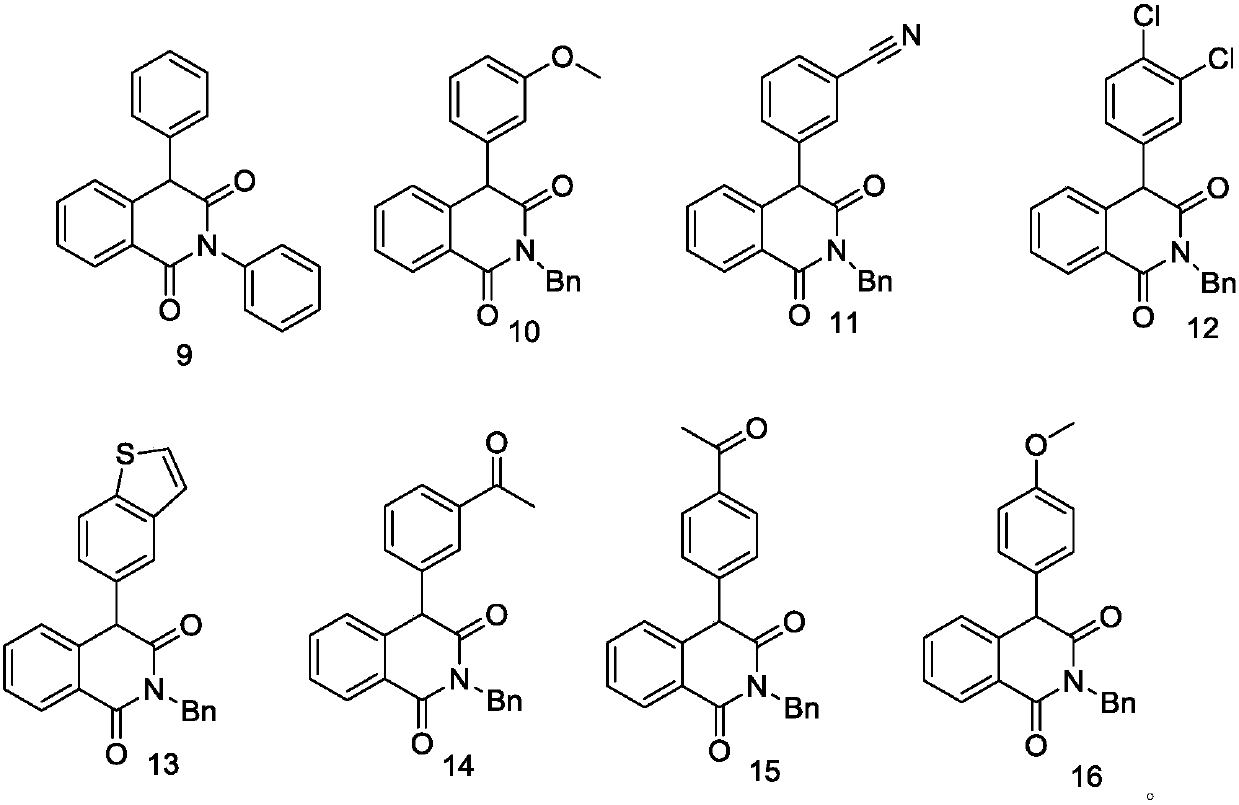

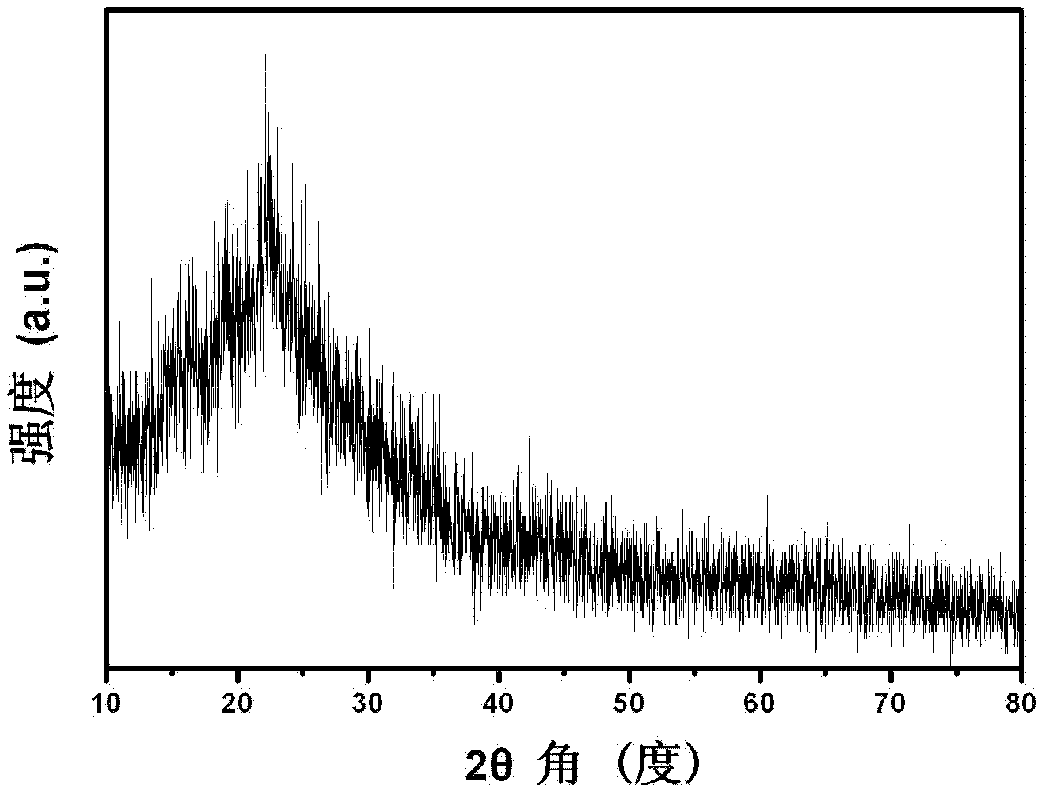

Preparation method for 4-aryl isoquinoline-1,3(2H,4H)-diketone compound

The invention provides a preparation method for a 4-aryl isoquinoline-1,3(2H,4H)-diketone compound. The preparation method comprises the following steps: in a solvent, with imide as shown in a formula(II) which is described in the specification as a raw material, and in the presence of a palladium catalyst, a ligand and alkali, allowing the imide to react with substituted aromatic hydrocarbon asshown in a formula (III) which is described in the specification so as to generate the 4-aryl isoquinoline-1,3(2H,4H)-diketone compound as shown in a formula (I) which is described in the specification. The preparation method provided by the invention has the advantages of stable operation, high yield, low production cost, etc.; preparation of a target object can be completed by a one-step reaction; the operation is simple and convenient; the yield is high and generally reaches 90% to 99%; the use of an expensive and hazardous reagent is avoided; a synthetic method with large-scale preparationvalues is realized; conditions are stable; the yield is high; and a selection for a novel preparation method is provided for development and application of an isoquinoline diketone compound. The preparation method provided by the invention has a synthetic route as described in the specification.

Owner:GUIZHOU MEDICAL UNIV

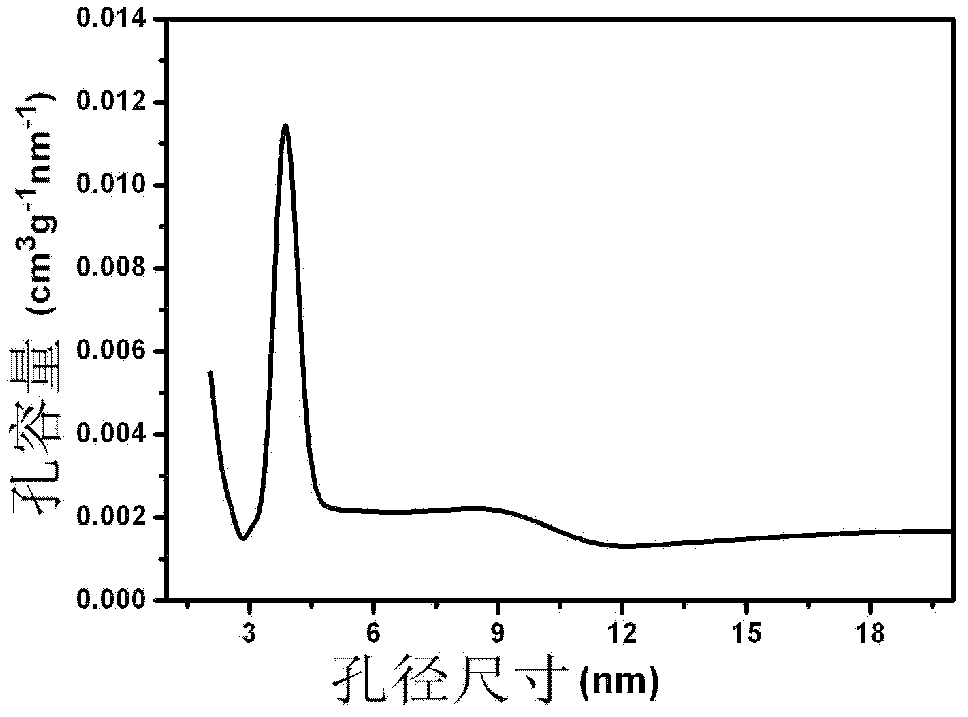

Method for preparing porous silicon

The invention relates to a method for preparing porous silicon. The method comprises the following steps of: (1) calcining a molecular sieve at high temperature and removing a template agent or deposited carbon; (2) diffusing the metal ions of the powder of the molecular sieve after being calcined and the elemental particles of metal into the molecular sieve under a vacuum condition by adopting a chemical gas / solid-phase reaction method and also reacting with the molecular sieve; and (3) taking out black solid after finishing the reaction in the step (2) from a reactor, washing repeatedly, filtering for several times and finally, drying so as to obtain a gray powder body, i.e. the porous silicon. Compared with the prior art, the reaction temperature can be lowered to a very large extent according to the method for preparing the porous silicon. The method for preparing the porous silicon has the advantage that a by-product can be removed very easily. Meanwhile, a silicon source material used by the reaction is expanded from pure silicon zeolite to a commercialized silicon-aluminum molecular sieve, the process is simple, and the operability is strong. The obtained porous silicon has the structural characteristic of a multi-stage pore taking a meso pore as a main part and has the advantages of very large specific surface area (which is not smaller than 420cm2 / g) and the like.

Owner:SHANGHAI JIAO TONG UNIV

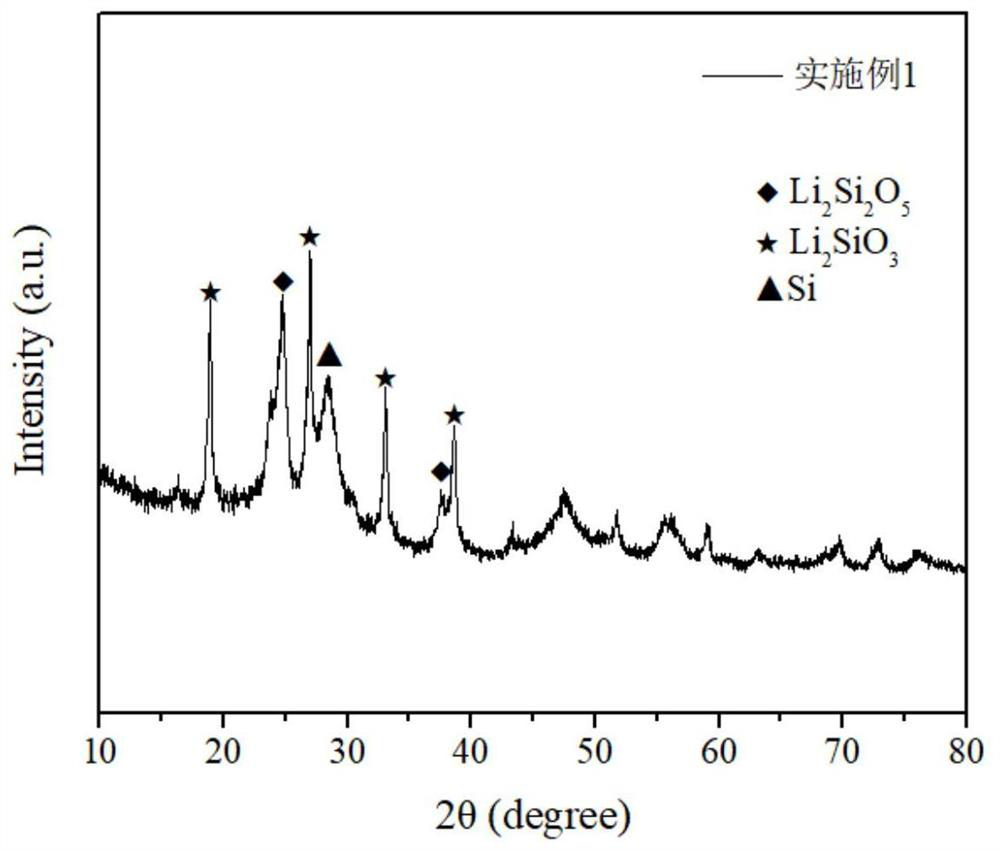

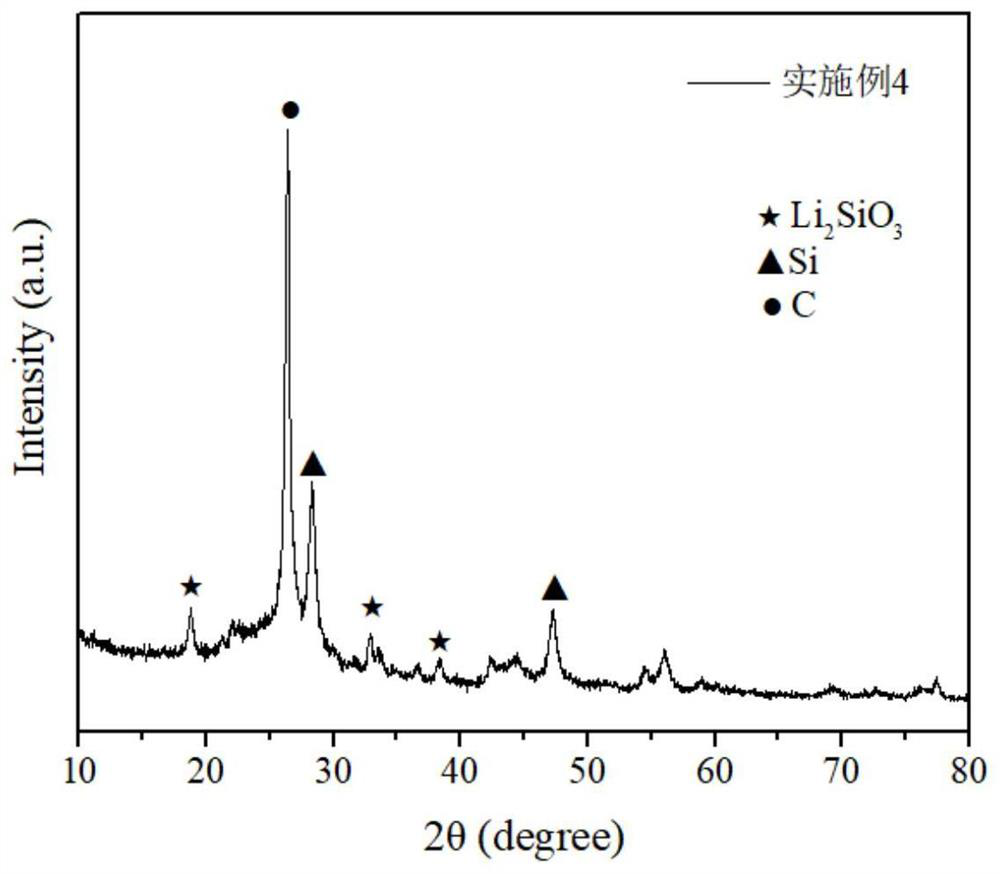

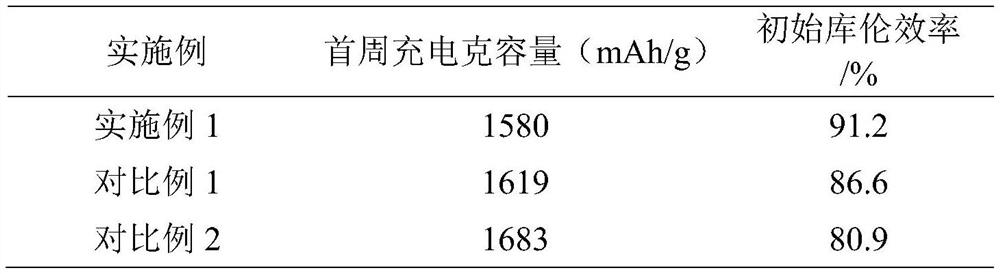

Lithium supplementing method of lithium ion battery negative electrode active material

ActiveCN112234160AImprove efficiencyImprove electrochemical performanceElectrode manufacturing processesNegative electrodesElectrical batteryAnalytical chemistry

The invention discloses a lithium supplementing method of a lithium ion battery negative electrode active material, which belongs to the field of lithium ion batteries. The lithium supplementing method is characterized in that a negative electrode active substance is added into an organic lithium solution in two stages to obtain a second-stage lithium supplementing active substance, and then the second-stage lithium supplementing active substance is added into an organic compound solution to be calcined and cleaned to obtain a lithium supplementing active substance product. According to the invention, a two-stage method is adopted to supplement lithium, so that a compact SEI film is formed on the surface of the active substance, the lithium supplementing degree of the active substance is higher, and higher initial coulombic efficiency is achieved; the initial coulombic efficiency and the electrochemical performance of the battery are obviously and effectively improved by supplementinglithium to the negative active material of the lithium ion battery. The method adopts an organic solution redox method to supplement lithium to the negative electrode active substance, is mild in process, controllable in lithium supplement amount and high in accuracy, is suitable for existing equipment, and is beneficial to industrial application.

Owner:SHAANXI COAL & CHEM TECH INST

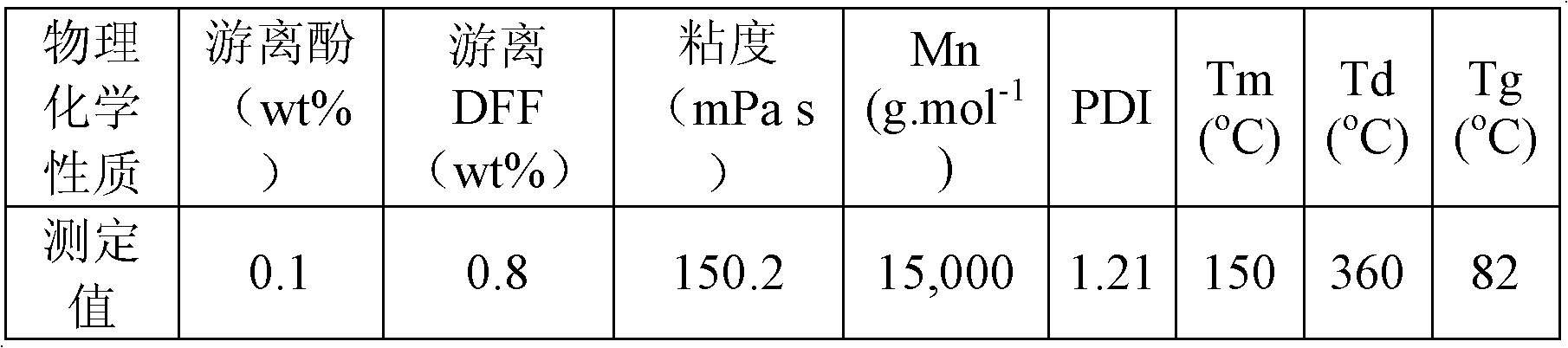

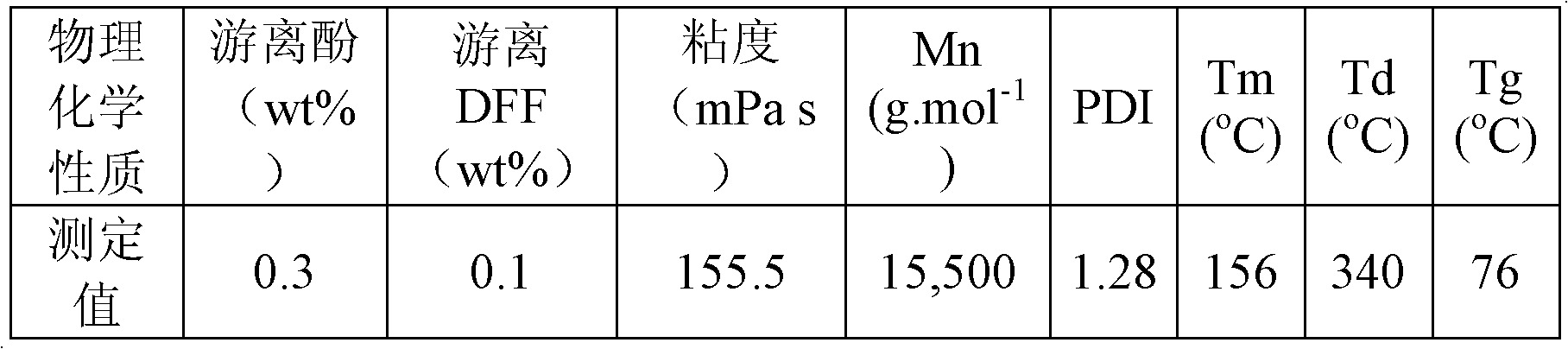

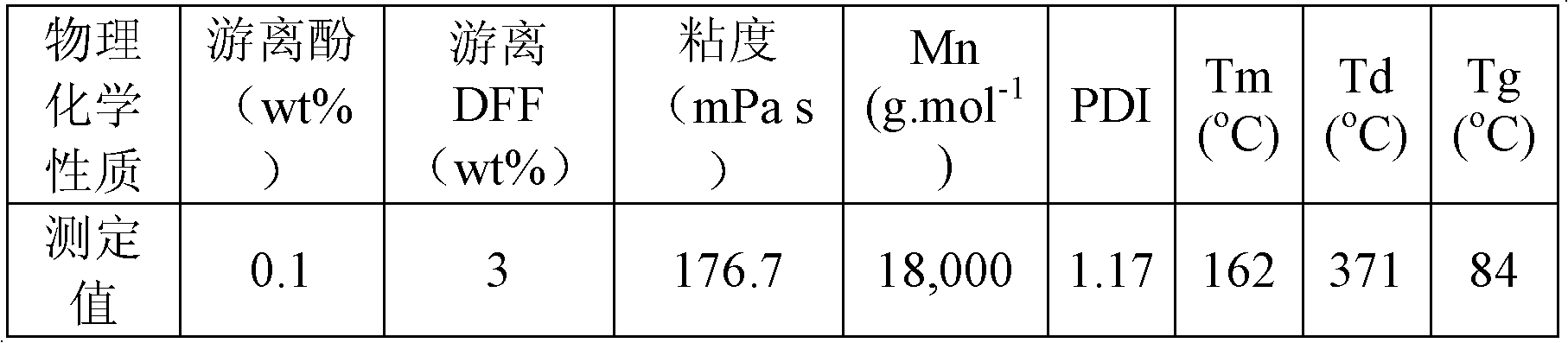

Biomass-based phenolic resin and preparation method thereof

The invention relates to a preparation method of a biomass-based phenolic resin. According to the invention, a biomass monomer 2,5-diformyl furan and phenol are adopted as raw materials; under the catalyzing of alkali, a temperature of 30-200 DEG C, and nitrogen gas protection, the raw materials are subjected to a addition and condensation reactions for 1-10h; and water and other impurities in the reaction system are removed with a vacuum distillation method, such that a novel phenolic resin high-quality product with 2,5-diformyl furan for substituting formaldehyde is obtained. With the method, the prepared product has the advantages of high yield, easy separation, and environment-friendliness. The method has good application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparation of polymer by molysite catalyzed atom transfer radical polymerization under natural light irradiation

A method of molysite-catalyzed atom transfer radical polymerization under natural light irradiation belongs to the technical field of high polymer chemical reaction methods. A monomer, an initiator, a molysite catalyst, a ligand of ferric salt and a reducing agent for radical polymerization are combined into a polymerization reaction system according to certain proportion for atom transfer radical polymerization under the natural light irradiation and in presence of oxygen to obtain a polymer after the reaction. The obtained polymer has the characteristics of living polymerization. The method is simple in conditions, easy in operation and energy-saving, and provides a simple-cost living polymerization technology.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

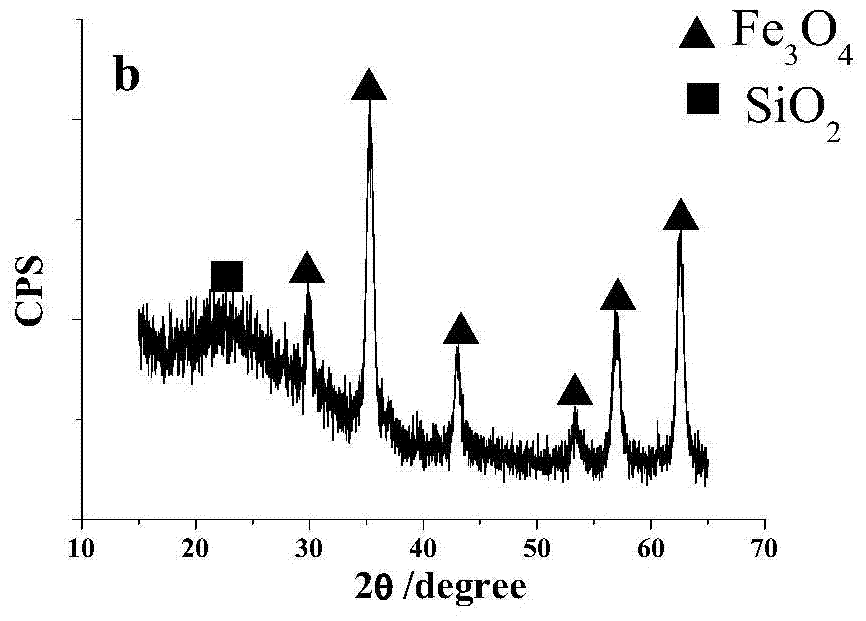

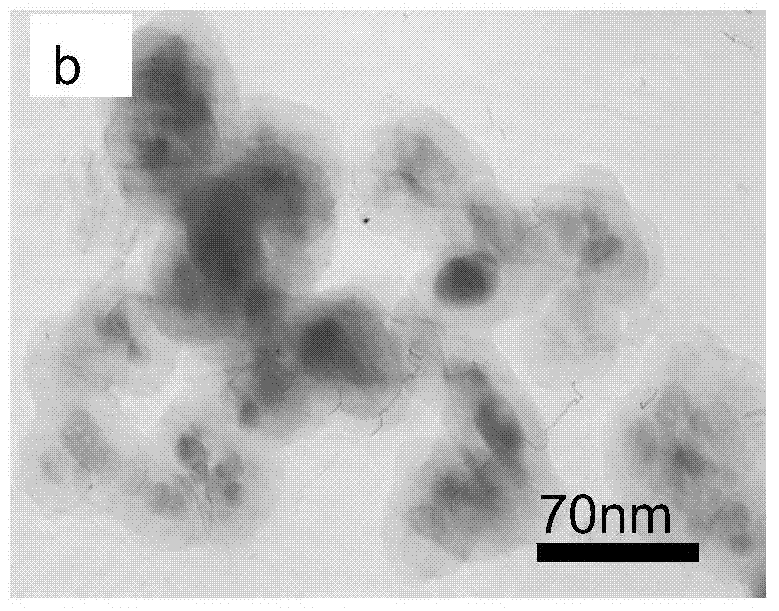

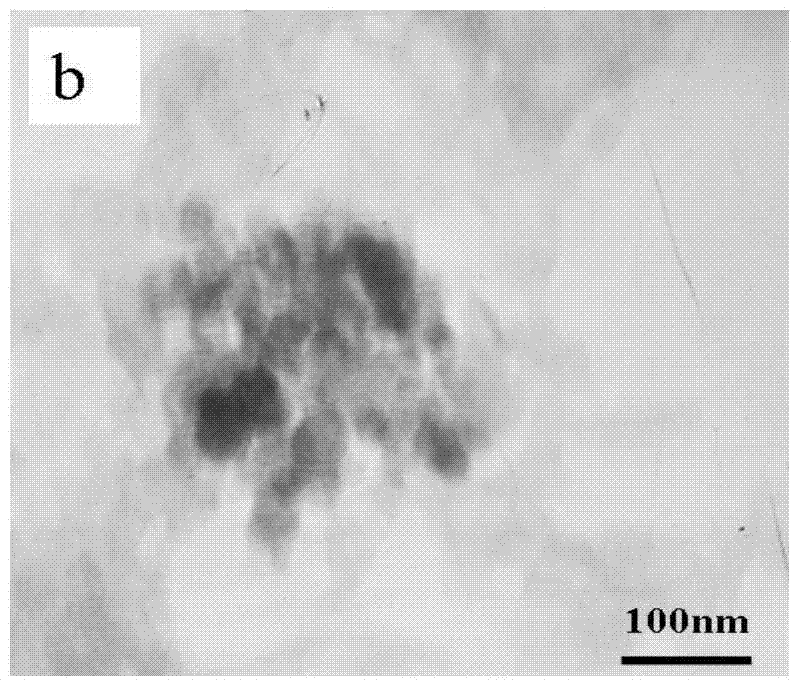

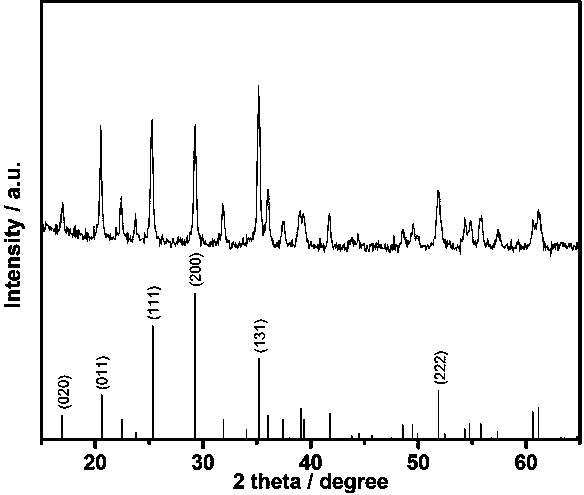

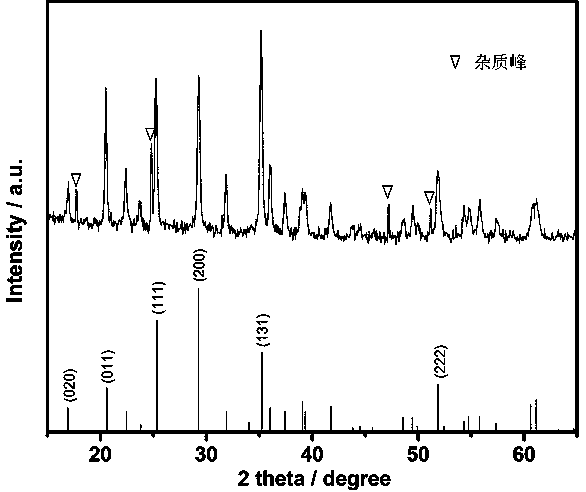

Preparation method of ferroferric oxide@silicon dioxide@zinc selenide fluorescent magnetic nanometer particles

InactiveCN103614143AMild reaction temperatureEasy to implementMaterial nanotechnologyInorganic material magnetismEmulsionFluorescence

The invention discloses a preparation method of ferroferric oxide@silicon dioxide@zinc selenide fluorescent magnetic nanometer particles. The preparation method is characterized in that the silicon dioxide grows on ferroferric oxide nano particles in situ, obtained ferroferric oxide@silicon dioxide particles are composited with quantum dots, and the ferroferric oxide@silicon dioxide@zinc selenide fluorescent magnetic nanometer particles are prepared by adopting a reverse micro-emulsion method. A device needed in the preparation method is simple, the preparation method is easily realized, the nanometer particles obtained through the method are unlikely to aggregate, and the granularity distribution is uniform.

Owner:TIANJIN UNIV

Method for preparing nano lithium manganese phosphate/graphene composite

InactiveCN105514376AAvoid harsh conditions of high temperature and pressureLow priceCell electrodesSecondary cellsLithium hydroxidePhosphoric acid

Owner:HENAN NORMAL UNIV

Preparation method of sulfur dioxide and epoxide copolymer

The invention discloses a preparation method of a sulfur dioxide and epoxide copolymer. According to the method, a novel polysulfone material is prepared through copolymerization of sulfur dioxide and epoxide under the catalytic action of SalenMX, epoxide and SalenMX are sequentially added to a high-pressure reaction kettle, sulfur dioxide is introduced and has a reaction at the temperature of 50-100 DEG C for 8-48 h, then, a product, namely, the sulfur dioxide and epoxide copolymer is obtained, the product is dissolved with chloroform, a hydrochloric acid and methanol mixed solution is used for precipitation, amber precipitates are filtered and repeatedly washed with methanol for 2-4 times, the washed product is transferred to a vacuum drying box and dried in vacuum at the room temperature for 8-24 h, and the sulfur dioxide and epoxide copolymer with higher stereoregularity can be obtained. The preparation method is simple, few catalysts are used, the reaction temperature is mild, the yield is high, the structure regularity of the product is good, the cost is low, and industrial production is easy to realize.

Owner:KUNMING UNIV OF SCI & TECH

Pyrogallic acid production method

ActiveCN103449977AMild reaction temperatureShort processing timeOrganic chemistryOrganic compound preparationWarming upAcid production

The invention provides a pyrogallic acid production method. The pyrogallic acid production method comprises the following steps of: mixing gallic acid and paranitroaniline in a mass ratio of 100: (2-2.5), putting the mixture in a reaction kettle, slowly heating to 140 DEG C till the mixture is melted completely; transferring the molten material to a subliming kettle, standing still for 20-30 minutes, opening a vacuum system, heating the subliming kettle, slowly warming up, controlling the temperature at 130 DEG C to 150 DEG C, and collecting a distilled subliming product till no subliming product is distilled, and thus the distilled subliming product is pyrogallic acid. The pyrogallic acid production method has the advantages that a special decarboxylation reagent, namely, the paranitroaniline, is selected, so that the gallic acid is subjected to a decarboxylation reaction at the temperature of 130-150 DEG C so as to generate the pyrogallic acid, the conversion rate of the gallic acid reaches above 98%, the yield of the high-quality product (analytical pure and chemical pure) reaches above 80%; and the reaction temperature in the method is mild, and the whole working procedure time is short.

Owner:湖北天新生物科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com