Lithium supplementing method of lithium ion battery negative electrode active material

A negative electrode active material and lithium-ion battery technology, which is applied in the direction of active material electrodes, battery electrodes, negative electrodes, etc., can solve the problem of low initial coulombic efficiency of negative electrode active materials, and is beneficial to industrial applications, and the amount of lithium supplementation is easy to control. The effect of improving the initial Coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

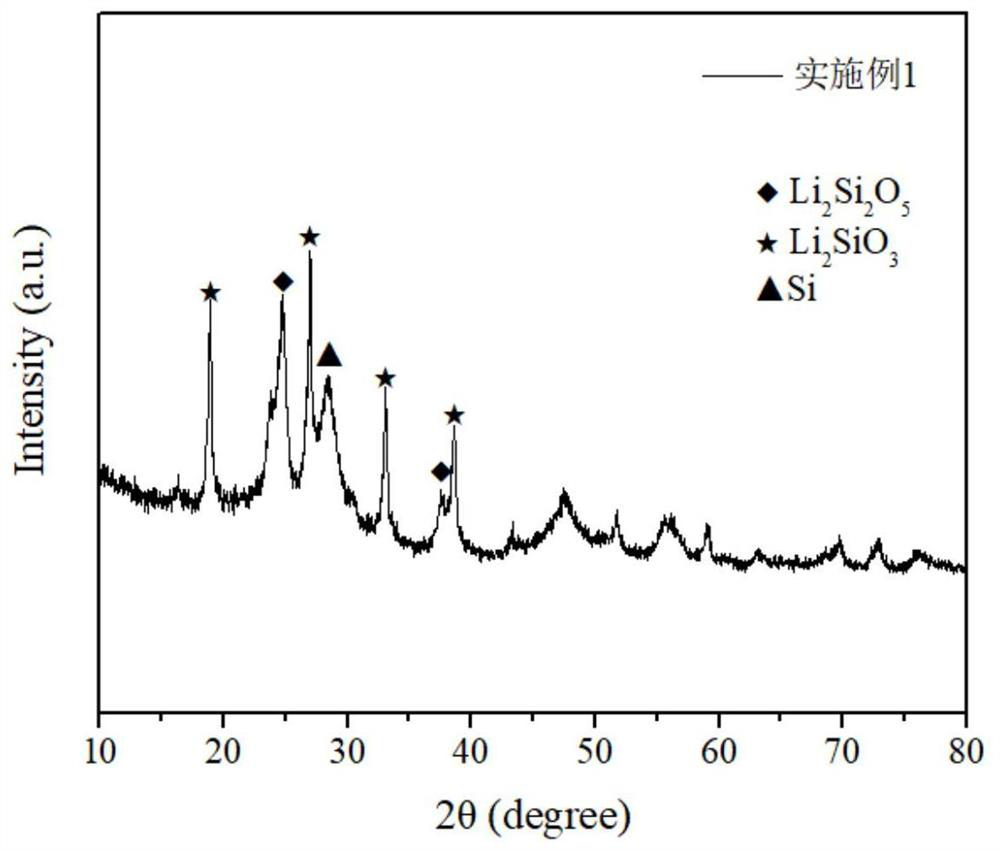

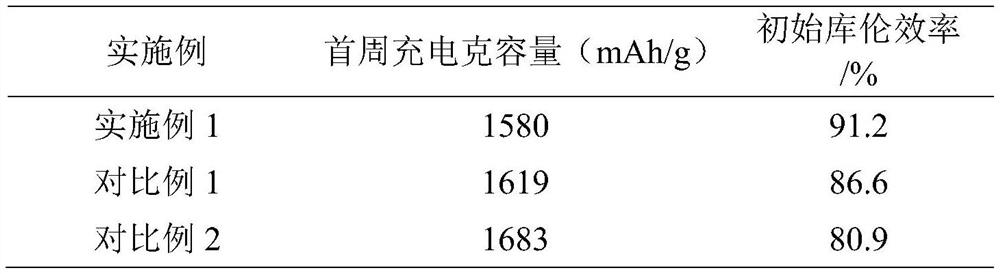

Embodiment 1

[0062] First, weigh 185.1g of biphenyl and 273.3g of 3,3'-dimethylbiphenyl and dissolve them in 1000mL of tetrahydrofuran and 1000mL of ethylene glycol dimethyl ether to obtain biphenyl solution and 3,3'-dimethylbiphenyl solution; then weigh 50g of lithium ingots and add them to biphenyl solution and 3,3'-dimethylbiphenyl solution respectively, after the lithium ingots dissolve Obtain organolithium solution F1 and organolithium solution G1;

[0063] Then, at 30°C, add 200g of silicon oxide into 1000mL of organolithium solution F1, mechanically stir for 14 hours and then filter, then add the filtered product to 800mL of organolithium solution G1, continue stirring for 8 hours, and then filter to obtain Lithium Supplement Silicon oxide J1; then add 150 g of lithium-supplemented silicon oxide J1 into 500 mL of 0.2 mol / L biphenyl solution, stir mechanically for 2.5 hours, filter, and dry to obtain lithium-supplemented silicon oxide K1;

[0064] Then put the obtained lithium-suppl...

Embodiment 2

[0067] First, weigh 1282.1g of naphthalene and 920.2g of 4,4'-dimethylbiphenyl and dissolve them in 1000mL of tetrahydrofuran respectively in a low-humidity -20°C environment filled with argon to obtain naphthalene solution and 4,4 '-dimethylbiphenyl solution; then weigh 350g and 525g of lithium flakes and add them to the naphthalene solution and 4,4'-dimethylbiphenyl solution, and the lithium flakes are dissolved to obtain organolithium solution F2 and organolithium solution G2 ;

[0068] Then at 10°C, add 250g of silicon oxide into 1000mL of organolithium solution F2, mechanically stir for 50h and then filter, then add the filtered product into 800mL of organolithium solution G2, continue stirring for 4h, and then filter to obtain Lithium Supplement Silicon oxide J2; then add 150 g of lithium-enriched silicon oxide J2 to 300 mL of 1 mol / L phenanthrene solution, mechanically stir for 72 hours, filter, and dry to obtain lithium-enriched silicon oxide K2;

[0069] Then put the...

Embodiment 3

[0072] First, weigh 2.3g of p-terphenyl and 2.9g of 3,3',4,4'-tetramethylbiphenyl and dissolve them in 1000mL of tetrahydrofuran and 1000mL In the ethylene glycol dimethyl ether, obtain p-terphenyl solution and 3,3',4,4'-tetramethylbiphenyl solution; Then weigh 35g and 12g of lithium strips and add p-terphenyl solution and 3, In the 3',4,4'-tetramethylbiphenyl solution, the lithium strips are dissolved to obtain organolithium solution F3 and organolithium solution G3;

[0073] Then at 80°C, add 100g of hard carbon into 1000mL of organolithium solution F3, mechanically stir for 20h and then filter, then add the filtered product into 50mL of organolithium solution G3, continue stirring for 0.1h, and then filter to obtain lithium supplement Hard carbon J3; then add 12g of lithium-replenishing hard carbon J3 into 1200mL of 10mol / L anthracene solution, mechanically stir for 0.5h, filter, and dry to obtain lithium-replenishing hard carbon K3;

[0074] Then put the obtained lithium-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com