Preparation method of amide self-emulsifying water-borne epoxy resin curing agent

A technology of water-based epoxy resin and epoxy resin, which is applied in the preparation of self-emulsifying water-based epoxy resin curing agent, the field of amide-type self-emulsifying water-based epoxy resin curing agent and its preparation, and can solve the problem of the hydrophilicity of triethylenetetramine Insufficient, limited application and other problems, to achieve the effect of high economy, low reaction temperature and high cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

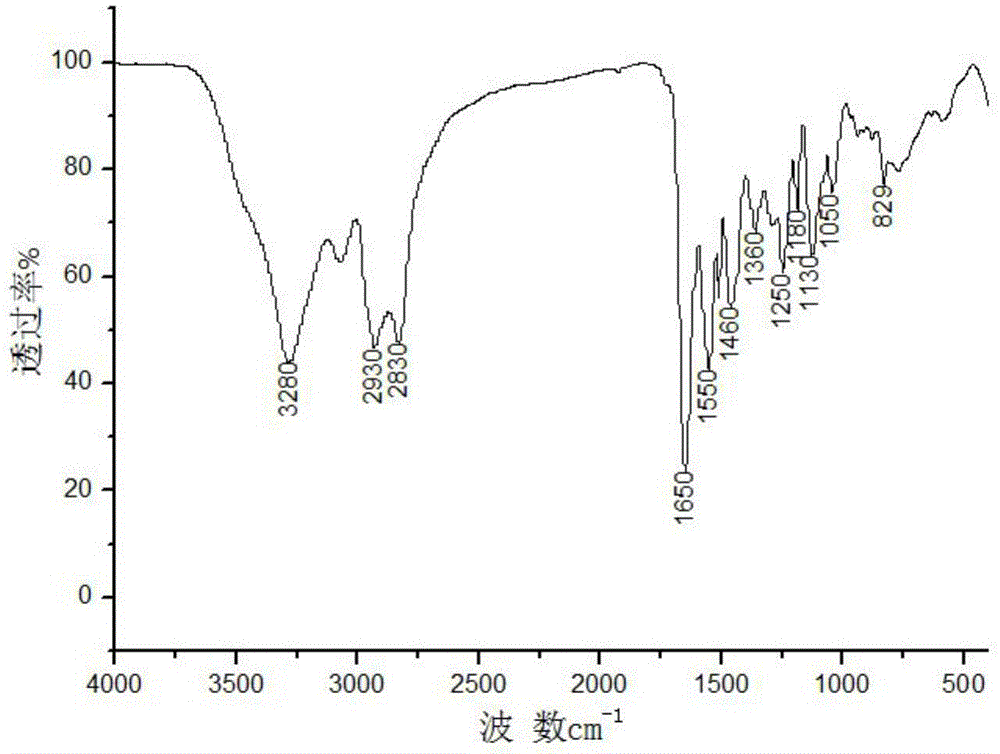

Image

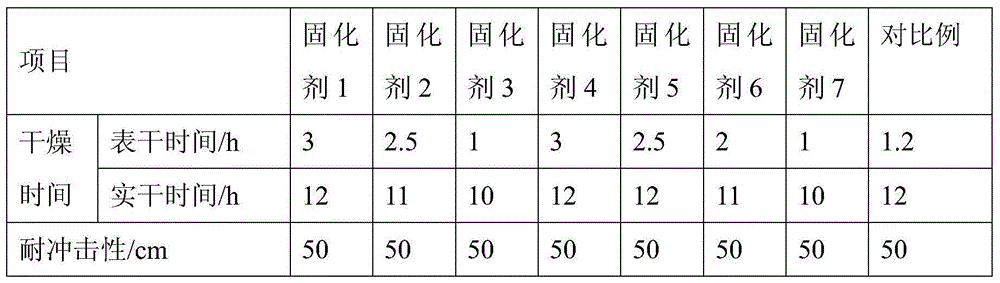

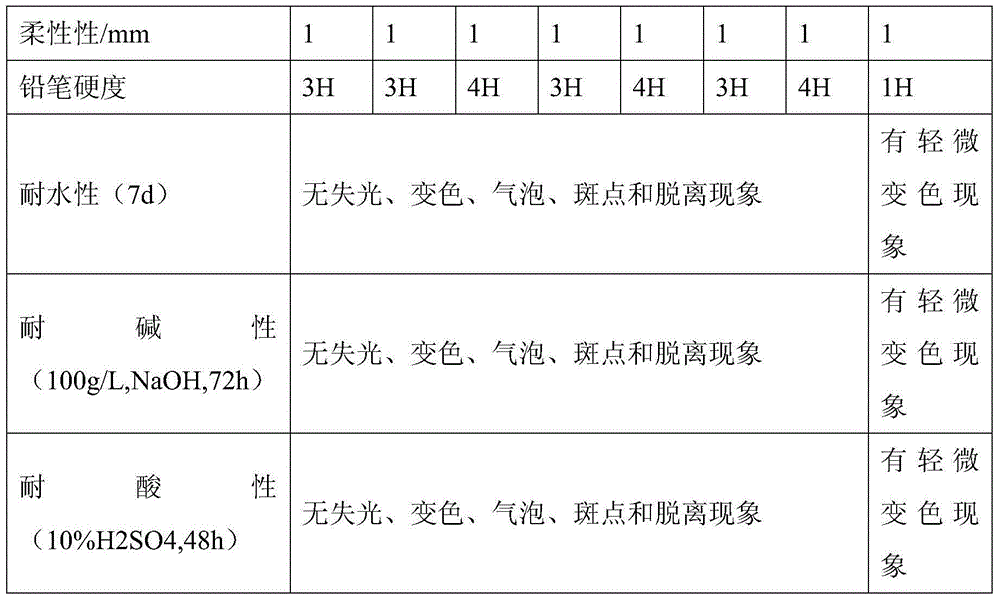

Examples

Embodiment 1

[0028] a. Add 103.2g diethylenetriamine and 28.4g methanol to the reactor equipped with heating device, reflux condensing device, constant pressure dropping funnel and stirring device, add 86.1g methyl acrylate dropwise at 25°C, dropwise Stir and add dropwise for 30 minutes. After the dropwise addition, continue to react at 25°C for 6h; then react at 70°C for 12h.

[0029] b. Add 184.0g of liquid epoxy resin E51 dropwise directly to the reactor in step a at 70°C, and stir while dripping. The dropwise addition time is 60min. After the dropwise addition, continue to react at 70°C for 2h; then at 75°C Evaporate methanol under normal pressure, and finally add 511.9 g of deionized water at 75°C and mix evenly so that the solid content is 40%, which is the amide type self-emulsifying water-based epoxy resin curing agent 1.

Embodiment 2

[0031] a. Add 146.2g triethylenetetramine and 45.6g methanol to the reactor equipped with heating device, reflux condensing device, constant pressure dropping funnel and stirring device, add 82.0g methyl acrylate dropwise at 28°C, dropwise Stirring, the dropwise addition time is 45min, continue to react at 28°C for 5h after the dropwise addition is completed; then react at 65°C for 18h.

[0032] b. Add 222.0g of liquid epoxy resin E51 dropwise directly to the reactor in step a at 65°C, and stir while dripping. The dropping time is 80min. After the dropwise addition, continue to react at 65°C for 3h; then, at 65°C Evaporate methanol under normal pressure, and finally add 419.7g deionized water at 65°C and mix evenly so that the solid content is 50%, which is the amide type self-emulsifying water-based epoxy resin curing agent 2.

Embodiment 3

[0034] a. Add 189.3g of tetraethylenepentamine and 80.3g of methanol to the reactor equipped with heating device, reflux condensing device, constant pressure dropping funnel and stirring device, add 77.5g of methyl acrylate dropwise at 30°C, dropwise Stir and add dropwise for 60 minutes. After the dropwise addition, continue to react at 30°C for 4h; then react at 60°C for 24h.

[0035] b. Add 294.0g of liquid epoxy resin E51 dropwise directly to the reactor in step a at 60°C, and stir while dropping. Distill methanol out under normal pressure, and finally add 354.6g of deionized water at 70°C and mix evenly so that the solid content is 60%, which is the amide type self-emulsifying water-based epoxy resin curing agent 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com