Preparation method of hydrofluoroether

A technology of hydrofluoroethers and fluorine-containing alkanols, which is applied in the field of preparation of hydrofluoroethers, can solve the problems of harsh reaction conditions and difficult availability of raw materials, and achieve easy recycling and reuse, suppress the generation of double bond impurities, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

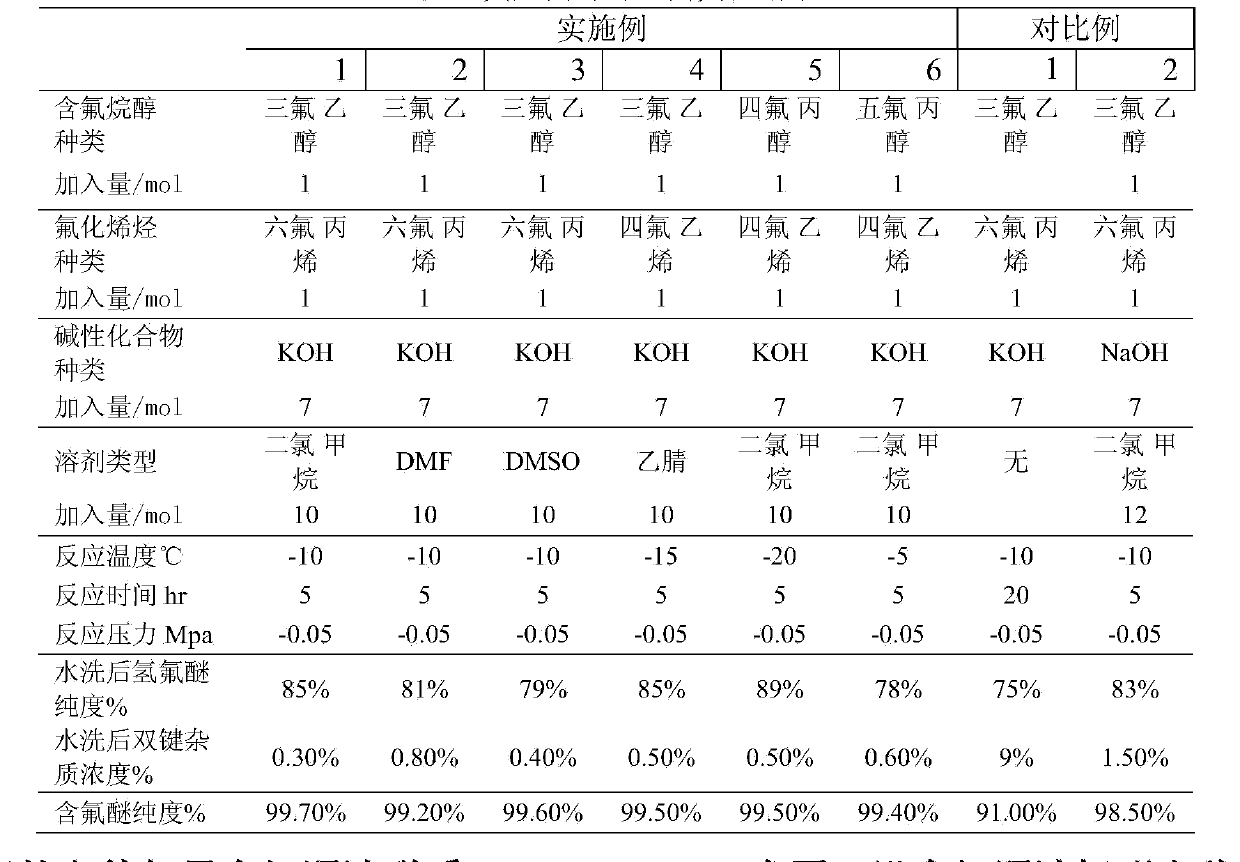

Examples

Embodiment 1

[0027] Step A

[0028] Evacuate the 10L high-pressure reactor, replace with nitrogen for 3 times, dissolve potassium hydroxide in trifluoroethanol, add it into the reactor after it is completely dissolved, then add dichloromethane, stir, keep at a certain temperature, and introduce hexafluoropropylene under vacuum , keeping the pressure inside the kettle constant.

[0029] Step B

[0030] When the added amount of hexafluoropropylene was 1 time of the molar number of trifluoroethanol added, stop inputting hexafluoropropylene. When the pressure in the reactor drops to negative pressure, add pure water, continue to stir for 0.5 hours, stop stirring, vent and discharge.

[0031] Step C

[0032] Divided into two layers, the upper layer is water, dichloromethane, potassium hydroxide and unreacted trifluoroethanol are dissolved in the water, and the lower organic layer is separated. The purity of the target product hydrofluoroether in the organic layer was 86%, and the proportion...

Embodiment 2

[0036] Steps A to D were implemented as in Example 1, except that dichloromethane was changed to DMF in step A, and the results are listed in Table 1.

Embodiment 3

[0038] Steps A to D were carried out as in Example 1, except that dichloromethane was changed to DMSO in step A. The results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com