Triphase catalyst UiO-67-IM and preparation method and application thereof

A catalyst, the uio-67-im technology, is applied in catalytic reactions, chemical instruments and methods, physical/chemical process catalysts, etc. It can solve the problems of high reaction temperature, long time-consuming, low yield, etc. Ease of recycling and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

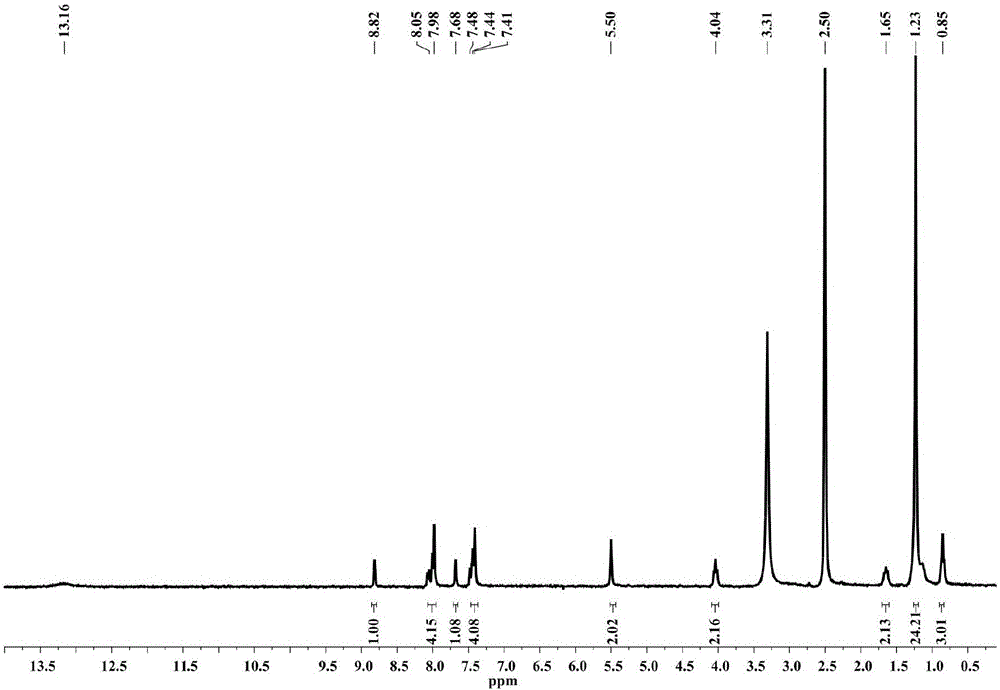

[0045] Embodiment 1: the preparation of organic ligand L

[0046] Concrete preparation steps are as follows:

[0047] (1)N 2 Under protection, methyl 4-bromo-3-methylbenzoate (5mmol, 1.15g), 4-methoxycarbonylphenylboronic acid (5.1mmol, 0.92g), CsF (20mmol, 3.0g), placed in a 100ml three-necked flask Add Pd catalyst 5% (0.3 ~ 0.5g), 50ml of anhydrous THF as a solvent, reflux at 67 ° C, after the reaction, silica gel column chromatography to separate the product (petroleum ether, dichloromethane) to obtain a pink solid 1.05g , yield 74%.

[0048]

[0049] (2) Intermediate A (8.96mmol, 2.54g), NBS (10.3mmol, 1.83g), AIBN (0.90mmol, 0.15g), was placed in a 100ml round bottom flask, and 45ml of carbon tetrachloride was added as a solvent, 90 Reflux at ℃ for 3h, track the reaction by thin-layer column chromatography (ethyl acetate: n-hexane = 2:8), after the reaction, filter, wash the filter cake with dichloromethane, combine the filtrates, evaporate the solvent under reduced...

Embodiment 2

[0058] Embodiment 2: Synthesis of UiO-67-IM

[0059] ZrCl 4 (0.12mmol, 28.8mg), 50 equivalents of acetic acid, DMF4.8ml was added to the beaker, ultrasonicated for 30min, the organic ligand L (0.12mmol, 68.31mg) prepared in Example 1 was added and continued ultrasonicated for 20min, put into a kettle, put into pre-heated Place in an oven at 120°C, keep the temperature constant for 24 hours, after the reaction is completed, cool to room temperature, centrifuge, take out the precipitate, soak in DMF solution at 80°C for 2 hours, centrifuge, soak the precipitate in 70°C absolute ethanol solution for 12 hours, repeat the ethanol soaking three times , The precipitate was taken out and dried under high vacuum to obtain 0.04g. Yield: 47.3% (based on L).

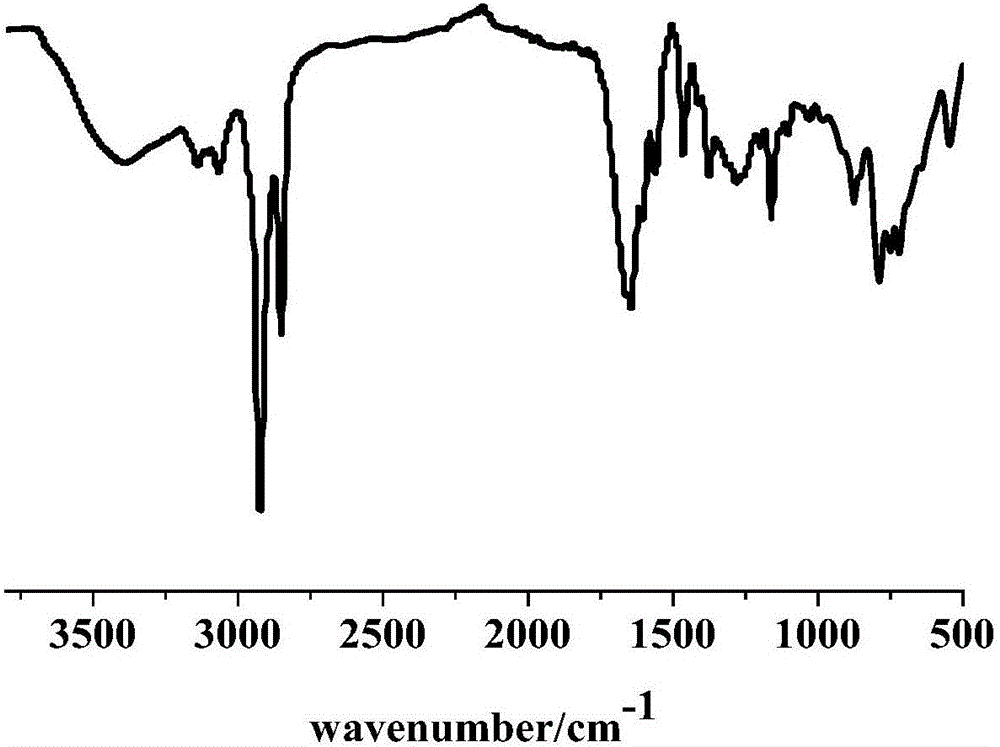

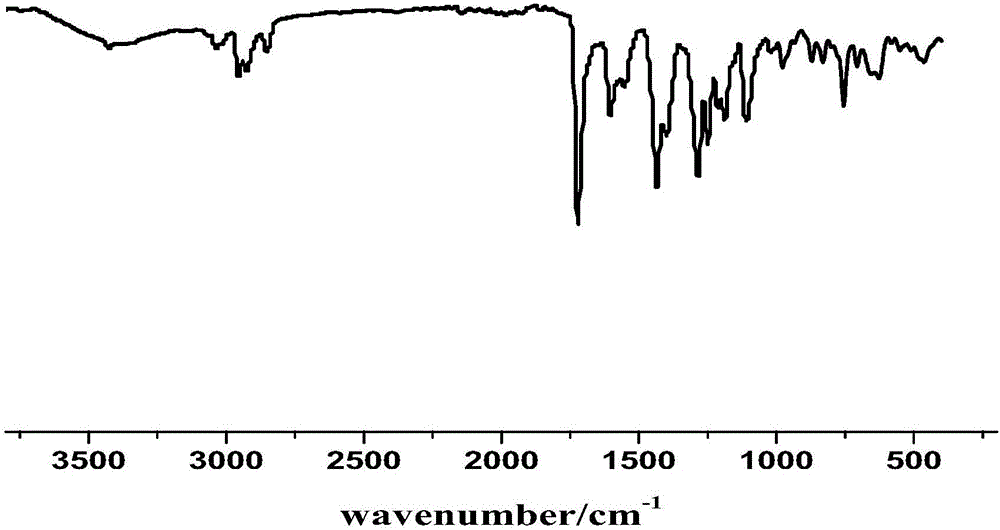

[0060] We characterized the compound by IR, TGA, and PXRD, and the results are shown in 3, 4, and 5, respectively.

Embodiment 3

[0062] Take benzyl chloride (1mmol, 115.1uL), NaN 3 (2mmol, 0.13g), water 2mL into a 25mL single-necked round-bottom flask, stirred at room temperature for 5min, then added UiO-67-IM (0.02mmol, 0.014g) (catalyst dosage is based on imidazolium salt), heated to 80°C , maintain stirring reaction at 80°C, and track the reaction by gas chromatography (the reaction diagram is as follows Figure 6 shown). After the reaction, the reaction system was lowered to room temperature, 2ml of double distilled water and 5mL of dichloromethane were added, fully extracted, liquid separated, the organic phase and the aqueous phase were rapidly centrifuged, the catalyst was recovered, and directly put into the next reaction, and the catalyst was used for 5 cycles , the organic phase is tested by gas chromatography to calculate the yield, and the catalytic effect is shown in Table 1. The recovered catalyst was characterized by PXRD, and UiO-67-IM still kept its original framework (as Figure 7 sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com