Graphene-supported palladium catalyst, preparation method and application thereof

A palladium catalyst and graphene technology, applied in chemical instruments and methods, preparation of organic compounds, physical/chemical process catalysts, etc., can solve the time-consuming and labor-intensive decolorization of activated carbon, the difficulty of uniform dispersion of reducing agents, and the large particle size of catalyst molecules and other problems, to achieve the effect of easy recycling and reuse, simplified post-processing operation, and small material particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A graphene-supported palladium catalyst, its raw materials include by volume: 2 parts of A material, 50 parts of ethylene glycol, 100 parts of graphene, KTiNbO 5 20 parts of nanosheet solution;

[0036] Wherein, the raw material of A material includes PdCl 2 and concentrations of 30% HCl, PdCl 2 The weight to volume ratio of hydrochloric acid g:ml is 0.1:10.

Embodiment 2

[0038] A graphene-supported palladium catalyst, its raw materials include by volume: 10 parts of A material, 30 parts of ethylene glycol, 150 parts of graphene, KTiNbO 5 5 parts of nanosheet solution;

[0039] Wherein, the raw material of A material includes PdCl 2 and a concentration of 37% HCl, PdCl 2 The weight-to-volume ratio of hydrochloric acid g:ml is 0.01:40.

Embodiment 3

[0041] A graphene-supported palladium catalyst, its raw materials include by volume: 4 parts of A material, 43 parts of ethylene glycol, 115 parts of graphene, KTiNbO 5 12 parts of nanosheet solution;

[0042] Wherein, the raw material of A material includes PdCl 2 and a concentration of 34% HCl, PdCl 2 The weight-to-volume ratio of hydrochloric acid g:ml is 0.1:20.

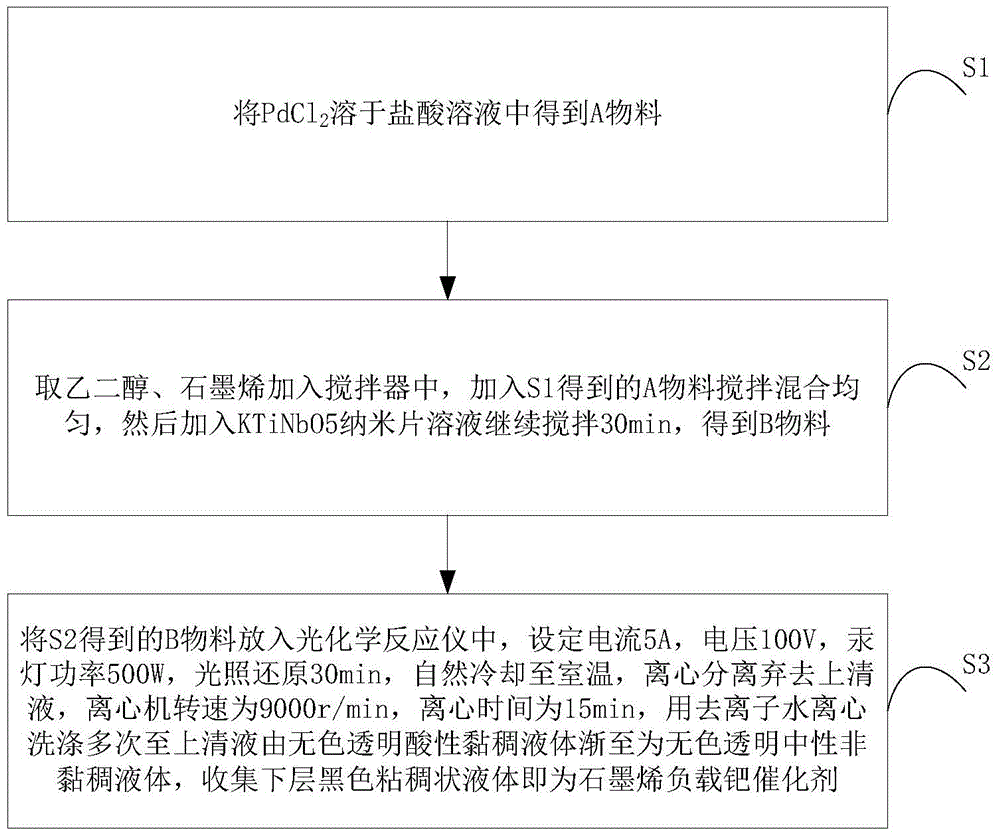

[0043] The preparation method of described graphene supported palladium catalyst is characterized in that, comprises the steps:

[0044] S1, the PdCl 2 Dissolved in hydrochloric acid to obtain material A;

[0045] S2. Add ethylene glycol and graphene to the stirrer, add the A material obtained in S1 and stir and mix evenly, then add the KTiNbO5 nanosheet solution and continue stirring for 20 minutes to obtain the B material;

[0046] S3. Put the material B obtained in S2 into a photochemical reaction apparatus, set current 6A, voltage 90V, mercury lamp power 550W, light reduction for 25min, cool to room temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com