Method for preparing porous silicon

A technology of porous silicon and molecular sieve, which is applied in the direction of silicon oxide and silicon dioxide, can solve the problems of non-application, difficulty in removing magnesium aluminum silicate gel, and affecting the purification of porous silicon, achieving mild reaction temperature, strong reducibility, Extremely easy to wash and remove effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

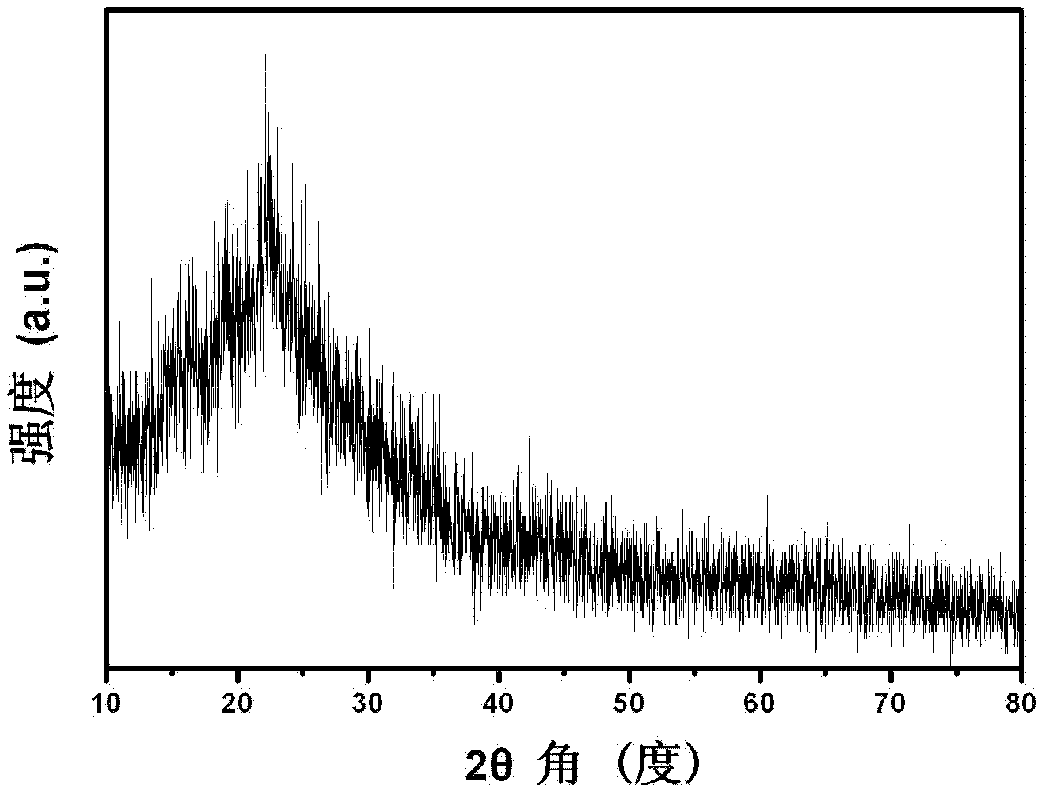

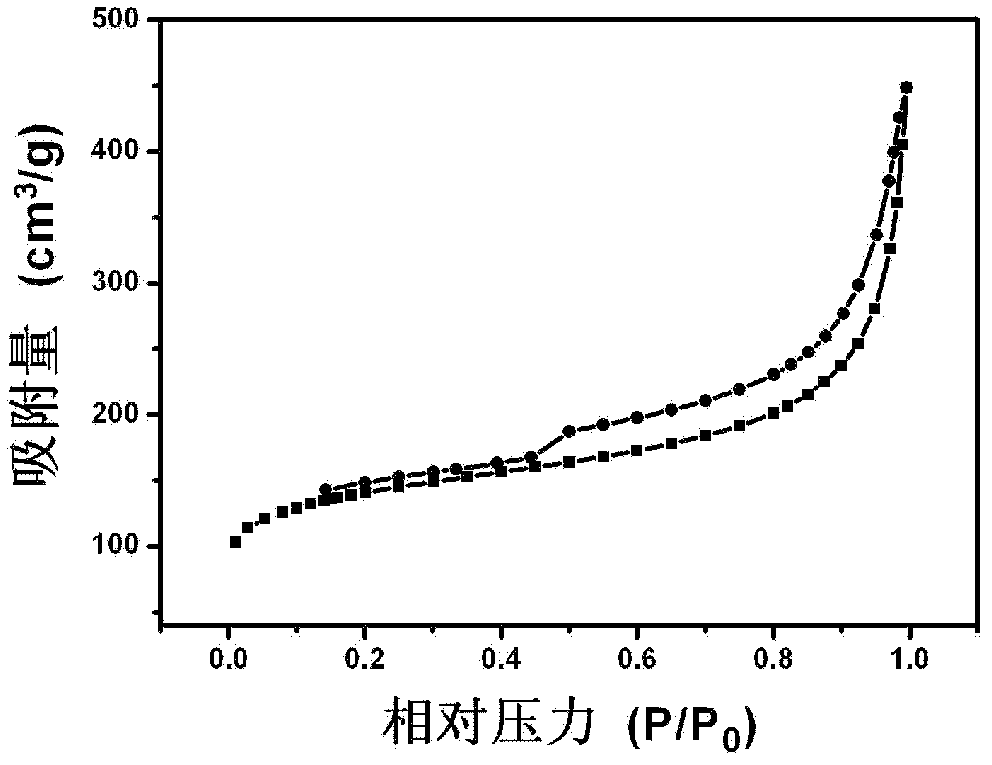

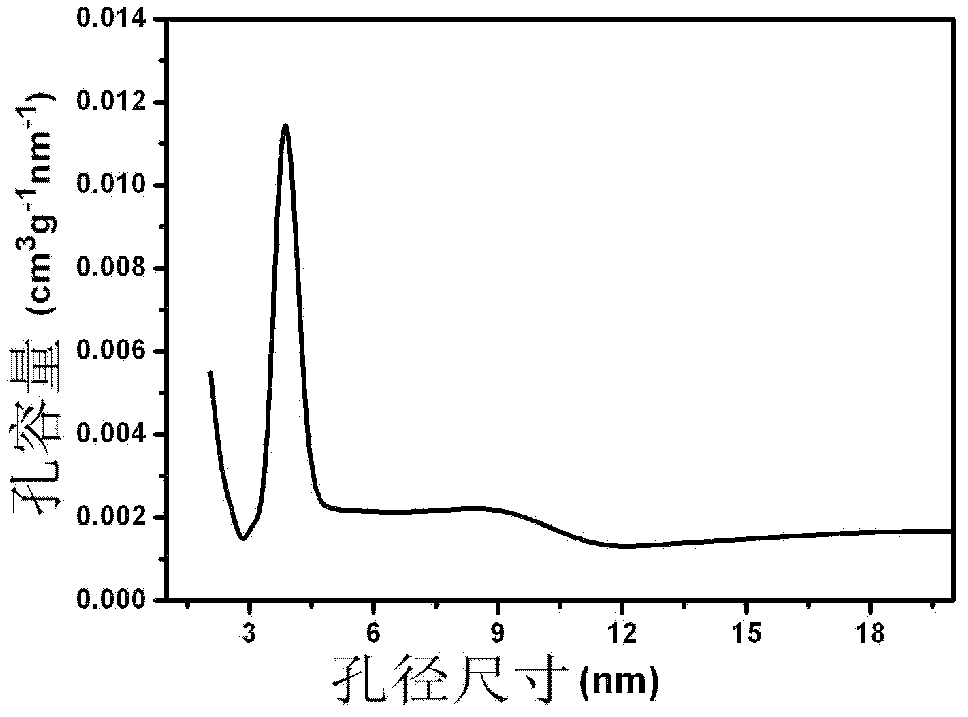

[0029] In the first step, 3.1 mmol of sodium microporous molecular sieve (NaZSM-5) was weighed and placed in a muffle furnace, and calcined at 600° C. for 4 hours in an air atmosphere to remove the template agent or surface carbon. The second step is to weigh 12.3mmol metal sodium block, wipe off the kerosene on the surface, cut it into 2-4mm diameter particles with scissors, and put it into a special hard glass tube at the same time as the molecular sieve. Connect the reactor to a vacuum system, and treat the molecular sieve under vacuum conditions (vacuum degree higher than 0.1MPa) to remove the adsorbed water and air, and use an oxygen flame to seal the glass reactor and leave the vacuum system. Put this airtight reactor into a tube furnace and heat it at 300°C for 20 hours to gradually reduce the molecular sieve by using the reducing property of metallic sodium vapor to obtain a black solid. The third step is to wash the black solid with 50 mL of absolute ethanol, centrifu...

Embodiment 2

[0032] The implementation method is the same as in Example 1, and the difference from Example 1 is that the main template material is a microporous sodium molecular sieve (NaY), and the porous silicon obtained is a hierarchical porous structure based on a mesoporous structure, and the specific surface area is 441.0m 2 / g, the pore size distribution is in the range of 2-60nm.

Embodiment 3

[0034]The implementation method is the same as in Example 1. The difference from Example 1 is that the reaction temperature of the chemical gas-solid method is different, which is 400 ° C. The porous silicon obtained is a hierarchical porous structure mainly based on a mesoporous structure, and the specific surface area is 462.1m 2 / g, the pore size distribution is in the range of 3-55nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com