Flexible electrochromic film based on tungsten oxide, and preparation method and application of flexible electrochromic film

A tungsten oxide and chromic technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of poor adhesion between tungsten oxide film and substrate, insufficient performance of color-changing film, affecting electrochromic performance, etc., and achieve equipment cost. Inexpensive, highly bendable, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

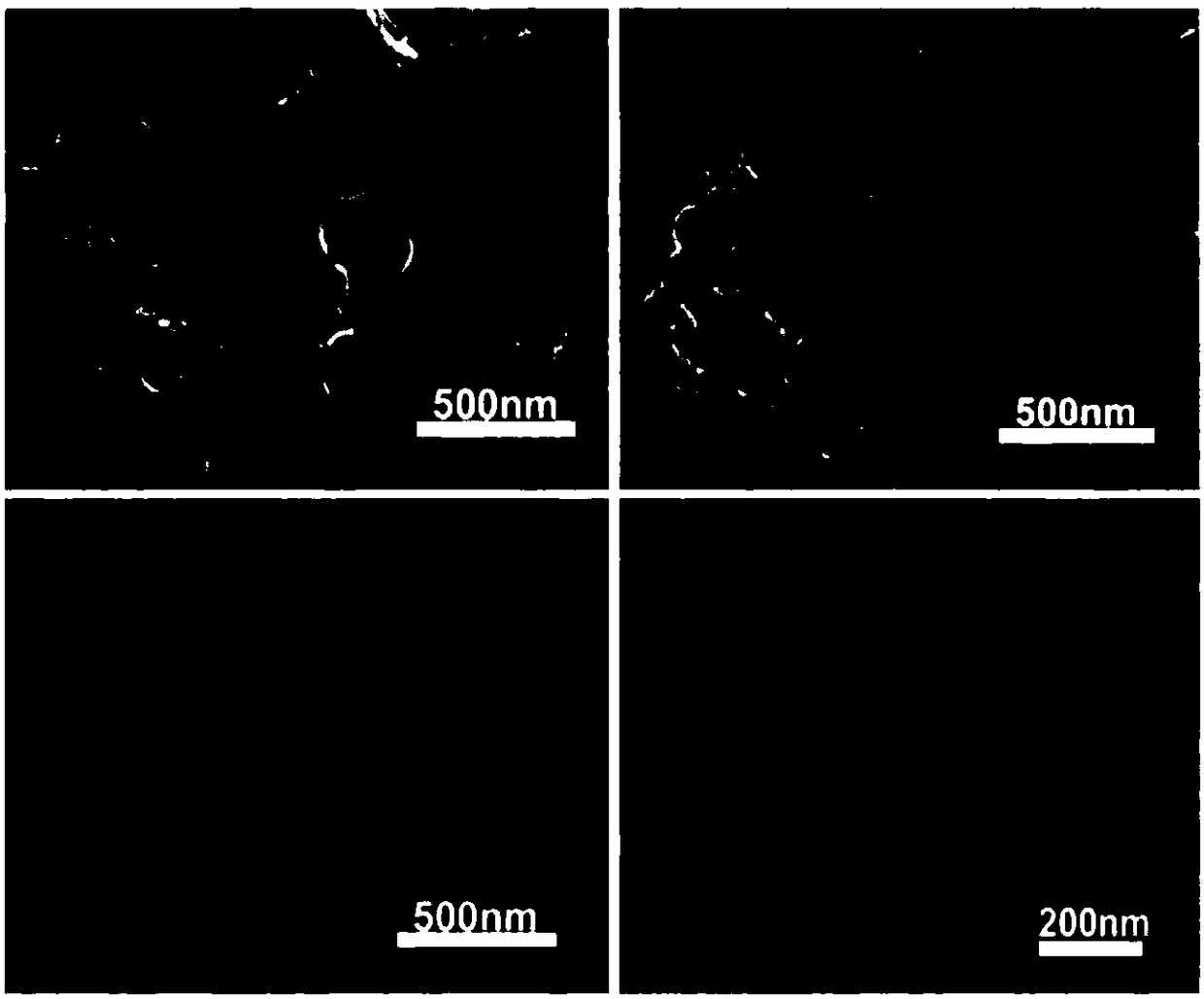

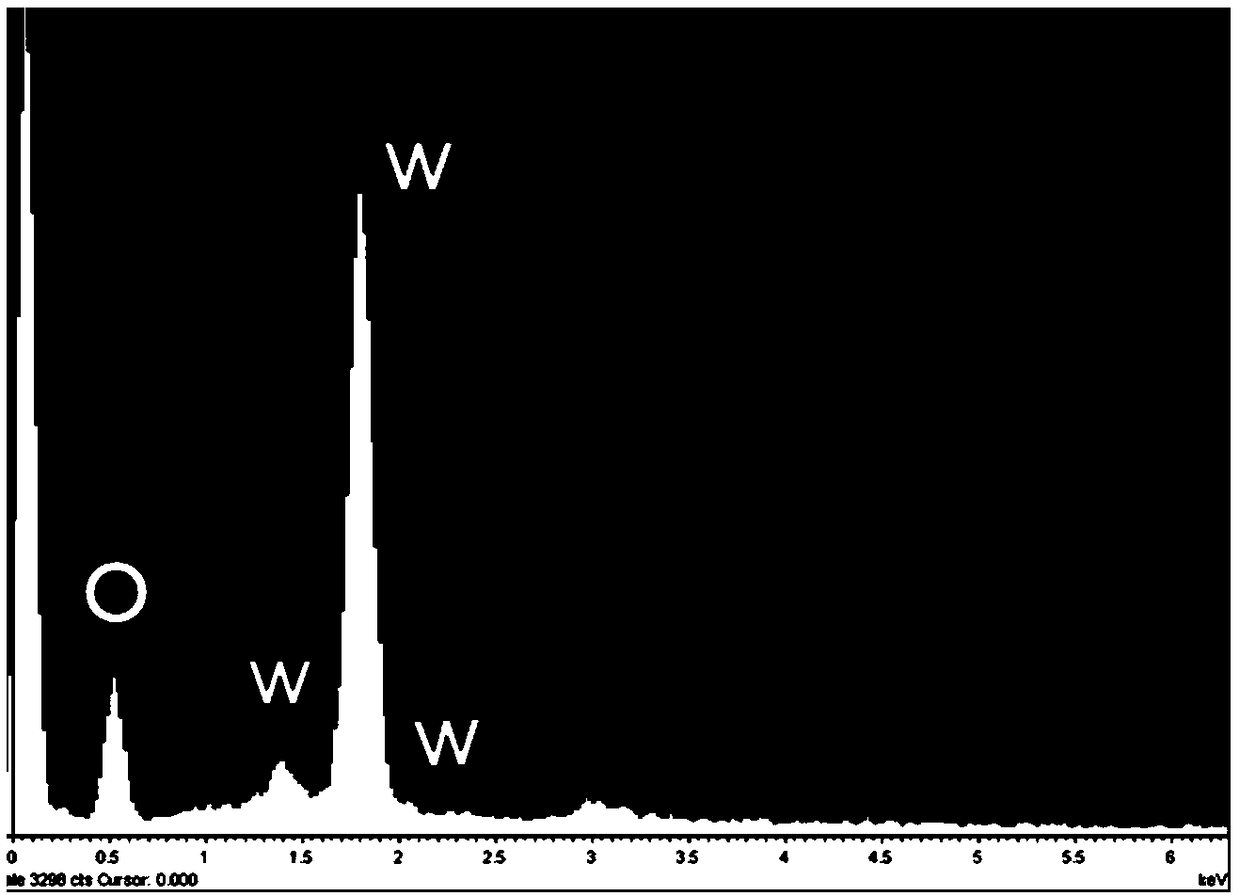

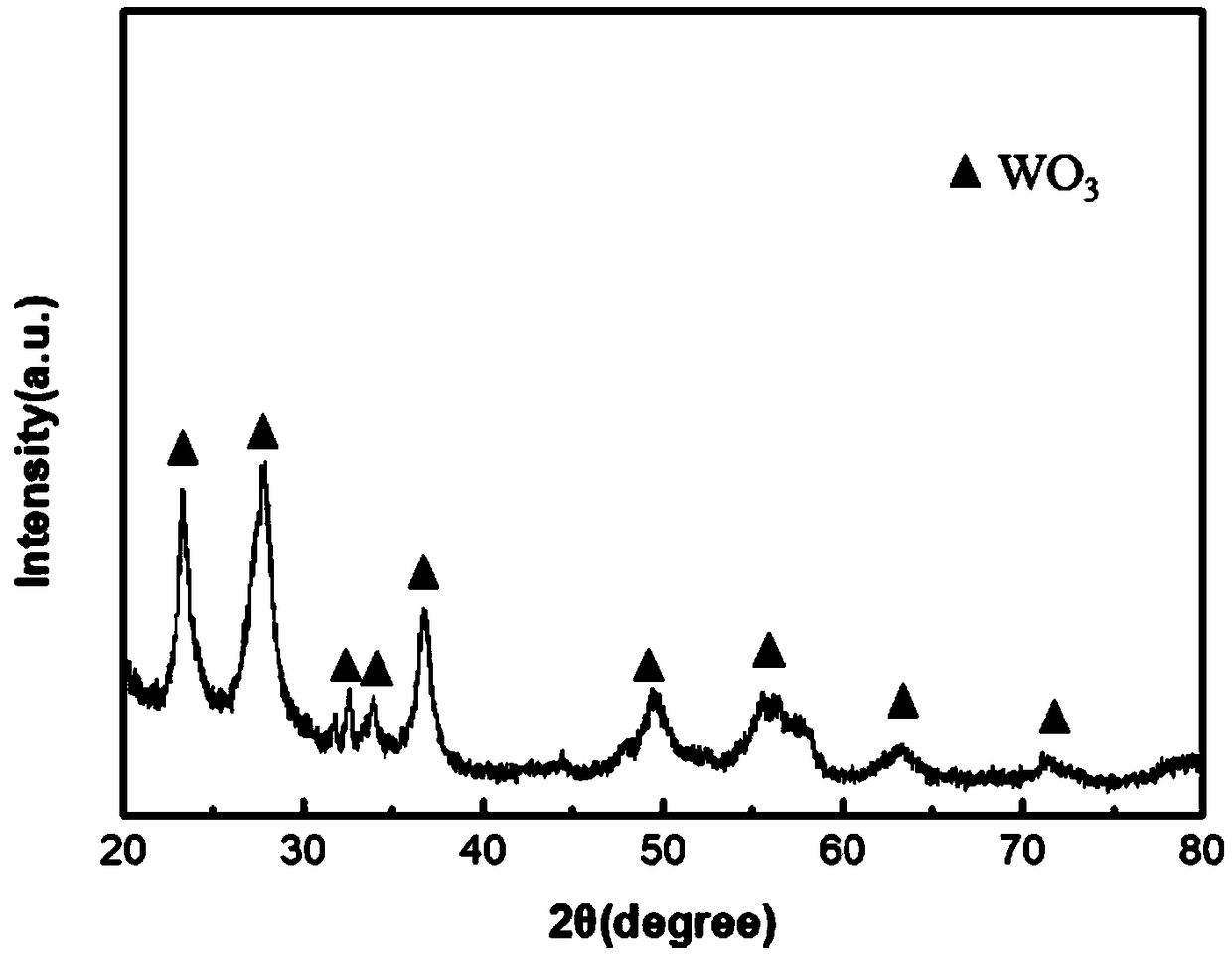

Image

Examples

preparation example Construction

[0030] The above-mentioned preparation method of the flexible electrochromic film based on tungsten oxide comprises the following steps:

[0031] (1) Flexible cleaning substrate: ultrasonically clean the flexible substrate in acetone, isopropanol, absolute ethanol, and deionized water in sequence, and then dry it naturally for use;

[0032] Among them, the flexible substrate is one of polyethylene terephthalate (PET), PI conductive film, silver-based transparent conductive film, and graphene-based transparent conductive film; the ultrasonic cleaning time is not less than 20 minutes;

[0033] (2) Spin-coating tungsten oxide precursor solution: dissolving the tungsten oxide precursor in absolute ethanol to prepare a tungsten oxide precursor solution, which is then spin-coated on the flexible substrate treated in step (1);

[0034] Among them, the tungsten oxide precursor is a mixture of one or more of tungsten hexachloride, tungsten pentachloride, tungsten tetrachloride, tungste...

Embodiment 1

[0043] In this embodiment, it is a flexible electrochromic film based on tungsten oxide, and its preparation method includes the following steps:

[0044] Step 1, substrate cleaning: ultrasonically clean the PET flexible substrate in acetone, isopropanol, absolute ethanol, and deionized water for 20 minutes to remove dust, organic matter and other stains on the surface, and then dry it naturally for use;

[0045] Step 2, spin-coating tungsten hexachloride precursor: Weigh 1.2g of tungsten hexachloride powder and dissolve it in 15mL of absolute ethanol, stir magnetically at 20°C for 20 minutes to obtain a tungsten oxide precursor, set the speed to 3000rpm, and the time to 30s. Spin-coat the tungsten oxide precursor on the PET flexible substrate;

[0046] Step 3, UV light deposition: transfer the PET flexible substrate obtained in step 2 to a UV light box with a wavelength of 185nm, and irradiate it for 3 minutes by means of ultraviolet light deposition, and repeat step 2 and st...

Embodiment 2

[0050] In this embodiment, it is a flexible electrochromic film based on tungsten oxide, and its preparation method includes the following steps:

[0051] Step 1, substrate cleaning: ultrasonically clean the PET flexible substrate in acetone, isopropanol, absolute ethanol, and deionized water for 30 minutes to remove dust, organic matter and other stains on the surface, and then dry it naturally for use;

[0052] Step 2, spin-coating tungsten hexachloride precursor: Weigh 2g of tungsten hexachloride powder and dissolve it in 20mL of absolute ethanol, stir magnetically at 30°C for 30min to obtain a tungsten oxide precursor, set the speed to 3500rpm, and the time to 45s. Spin-coat the tungsten oxide precursor on the PET flexible substrate;

[0053] Step 3, UV light deposition: transfer the PET flexible substrate obtained in step 2 to a UV light box with a wavelength of 254nm, and irradiate it for 3 minutes by means of ultraviolet light deposition, and repeat steps 2 and 3 altern...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com