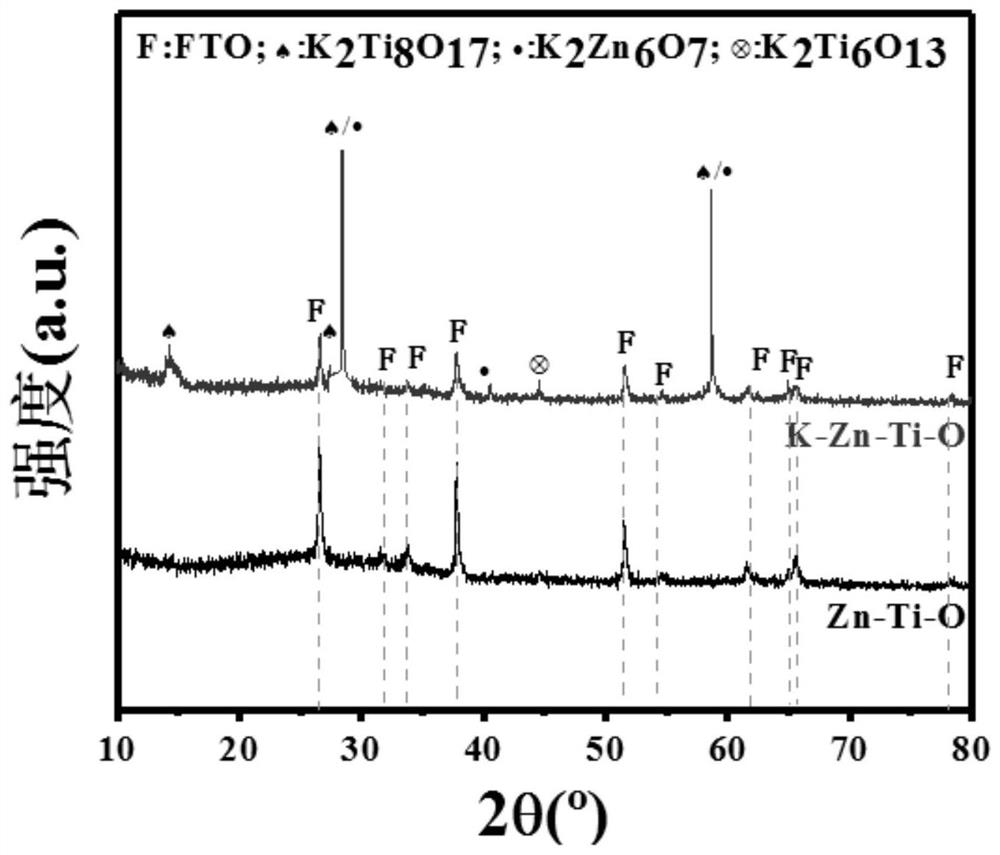

Zinc-titanium-oxygen composite film material with electrochromic effect, its application and preparation method

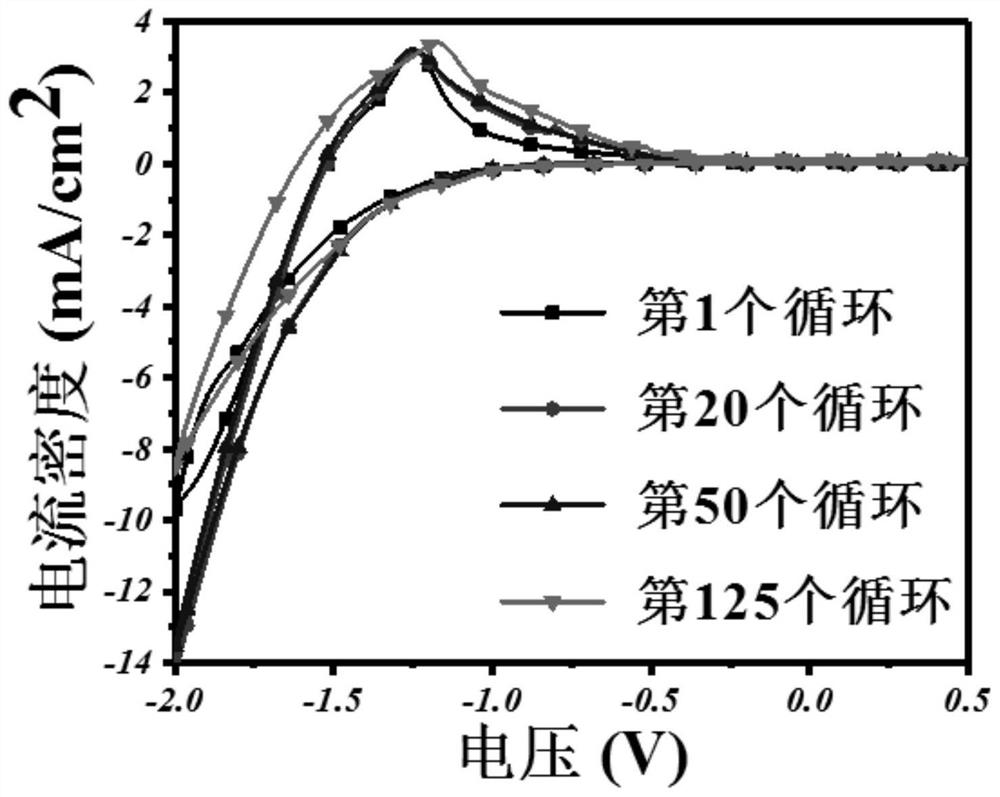

A composite film and electrochromic technology, applied in the fields of electrochromic materials and metal-oxygen composite materials, to achieve the effects of low cost, simple process and good cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

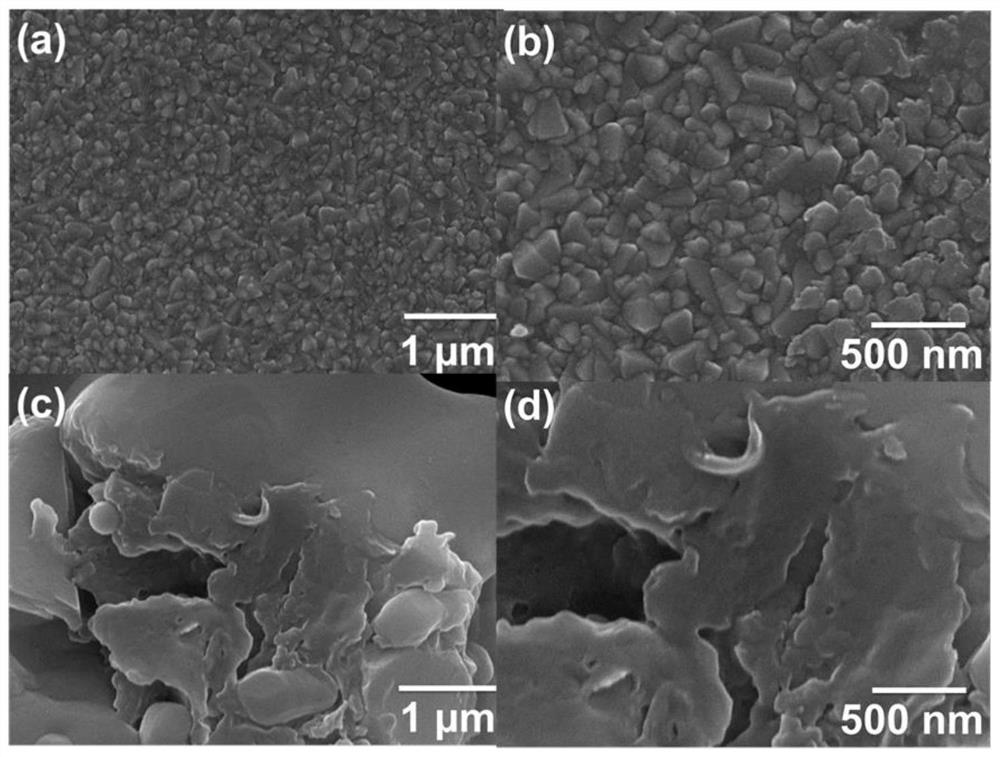

Embodiment 1

[0034] In this embodiment, a method for preparing a zinc-titanium-oxygen composite thin film material with an electrochromic effect according to the present invention is prepared by a sol-gel process, and the specific steps are as follows:

[0035] a. Substrate pretreatment:

[0036] First, pretreat the FTO conductive glass substrate, then ultrasonically clean the FTO conductive glass substrate with deionized water, acetone, absolute ethanol, and deionized water in sequence, and dry it to obtain a clean and dry substrate, which is ready for use;

[0037] b. Preparation of zinc-titanium-oxygen composite film precursor colloid:

[0038] According to the molar ratio of titanium dioxide and zinc oxide in the preparation of zinc-titanium oxide sol is 1:1, tetra-n-butyl titanate and zinc acetate are used as the raw materials for the preparation of the precursor solution, and diethanolamine and absolute ethanol are used as the raw materials respectively. Stabilizer and solvent, usin...

Embodiment 2

[0060] This embodiment is basically the same as Embodiment 1, especially in that:

[0061] In this embodiment, a method for preparing a zinc-titanium-oxygen composite thin film material with an electrochromic effect according to the present invention is prepared by a sol-gel process, and the specific steps are as follows:

[0062] a. This step is the same as in Embodiment 1;

[0063] b. Preparation of zinc-titanium-oxygen composite film precursor colloid:

[0064] According to the molar ratio of titanium dioxide and zinc oxide in the preparation of zinc-titanium oxide sol is 1:1, tetra-n-butyl titanate and zinc acetate are used as the raw materials for the preparation of the precursor solution, and diethanolamine and absolute ethanol are used as the raw materials respectively. Stabilizer and solvent, using F127 three-block block polymer ( SIGMA) as a surfactant, weighed 0.2049g of F127 three-stage block polymer with an analytical balance and placed it in a round-bottomed fla...

Embodiment 3

[0071] This embodiment is basically the same as the previous embodiment, and the special features are:

[0072] In this embodiment, a method for preparing a zinc-titanium-oxygen composite thin film material with an electrochromic effect according to the present invention is prepared by a sol-gel process, and the specific steps are as follows:

[0073] a. This step is the same as in Embodiment 1;

[0074] b. This step is the same as in Embodiment 1;

[0075] c. Zinc-titanium oxide composite oxide film coating:

[0076] Using the SC-1B desktop glue homogenizer, take the zinc-titanium oxide sol prepared in the step b, spin coating at a speed of 1000 rpm for 5 seconds, and spin coating at a speed of 4000 rpm for 25 seconds, Coating the zinc-titanium oxide sol on the FTO conductive glass substrate pretreated by the step a, forming a zinc-titanium oxide sol film through a sol coating process, as a zinc-titanium oxide composite oxide film precursor;

[0077] d. Heat treatment of z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com