Modified attapulgite and preparing method thereof

An attapulgite and modified technology, which is applied in the treatment of fibrous fillers and dyed low-molecular organic compounds, can solve the problems of high brittleness and poor curing process, and achieve the effects of high grade, blocking heat transfer, and mild reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of acidified attapulgite

[0030] Add 1 g of attapulgite to 50 mL of hydrochloric acid (5 mol / L), react at a constant temperature of 75 °C for 1 h, then filter with suction, wash with deionized water until neutral, and dry at 70 °C to obtain acidified attapulgite.

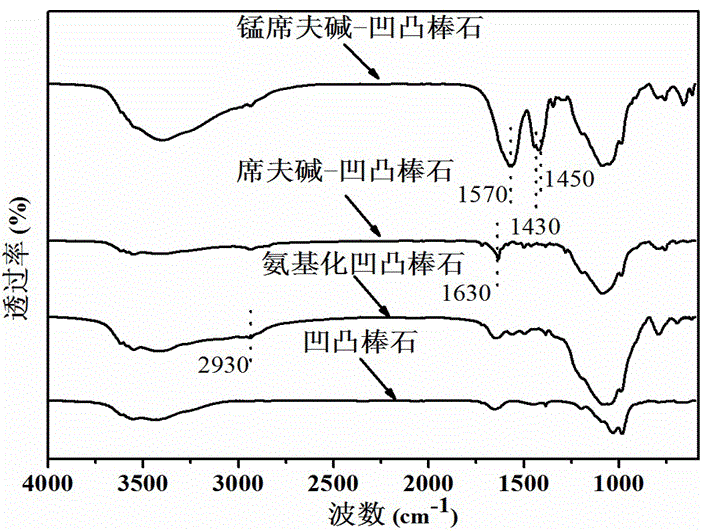

[0031] (2) Preparation of aminated attapulgite

[0032] Disperse 1 g of the acidified attapulgite prepared in step (1) in 60 mL of toluene, and disperse it ultrasonically for 30 minutes to obtain a uniform dispersion A; add 6 mL of γ-aminopropyltriethoxysilane to the dispersion A, and react at 90°C for 8h; filter with suction, wash with ethanol several times, and dry at 60°C to obtain aminated attapulgite.

[0033] (3) Preparation of Schiff base-attapulgite

[0034] Disperse 1 g of the aminated attapulgite prepared in step (2) in 100 mL of ethanol, and disperse it ultrasonically for 30 minutes to obtain a uniform dispersion B of the aminated attapulgite; under stirring conditions, add 16 mL...

Embodiment 2

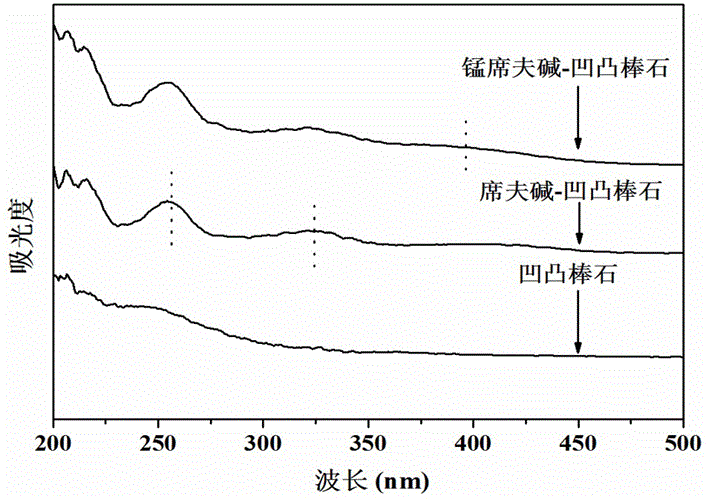

[0042] Disperse 1 g of the Schiff base-attapulgite obtained in step (3) of Example 1 in 100 mL of ethanol, and stir with a strong mixer for 25 min to obtain a uniform dispersion C of Schiff base-attapulgite; 2 Under protection and stirring conditions, add 4.52g of manganese acetate tetrahydrate to the dispersion C, and then reflux for 12 hours; then filter with suction, wash with ethanol several times, and dry at 65°C to obtain modified attapulgite.

[0043] Provide comparative example 1:

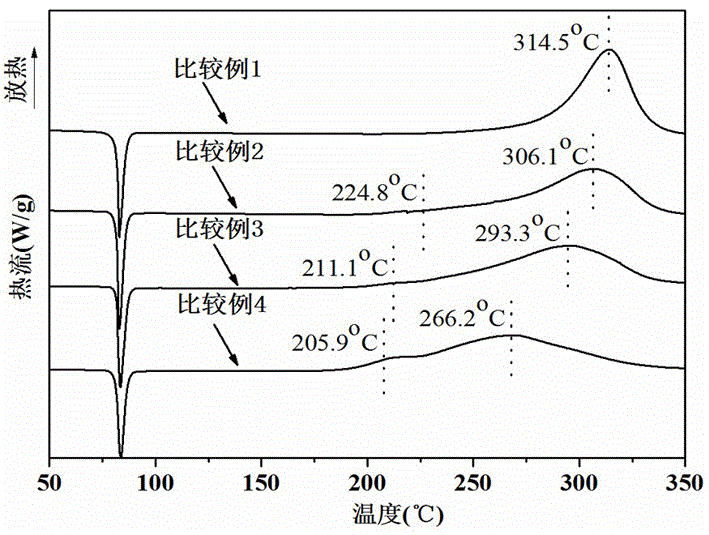

[0044] (1) Preparation of cyanate resin prepolymer

[0045] Stir 100g of 2,2'-bis(4-cyanophenyl)propane (also known as bisphenol A cyanate) at 90°C, and ultrasonically disperse for 40min; then stir at 140°C for 12min to obtain cyanide Ester resin prepolymer. Its differential scanning calorimetry (DSC) curve is shown in the appendix Figure 5 .

[0046] (2) Preparation of cyanate ester cured resin

[0047] Pour the cyanate ester prepolymer prepared in step (1) into the mold, vacuum dega...

Embodiment 3

[0070] Disperse 1 g of the Schiff base-attapulgite prepared in step (3) of Example 1 in 100 mL of ethanol, and disperse it ultrasonically at 40 mm to obtain a uniform dispersion C of Schiff base-attapulgite; 2 Under the conditions of protection and stirring, 1.98g of manganese acetate tetrahydrate was added to the dispersion C, and then refluxed for 12 hours; then suction filtered, washed with ethanol several times, and dried at 60°C to obtain modified attapulgite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com