A preparation method of graphene quantum dots with controllable oxidation degree

A technology of graphene quantum dots and oxidation degree, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem of low yield, unfavorable large-scale preparation of graphene quantum dots, and impurity removal Low efficiency and other problems, to achieve the effect of large processing capacity, high yield, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

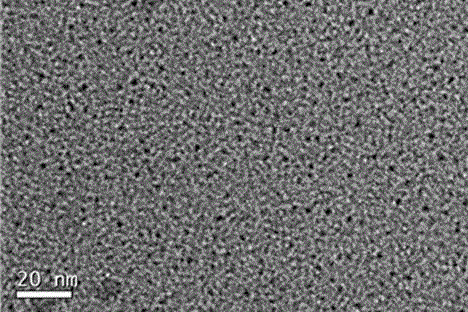

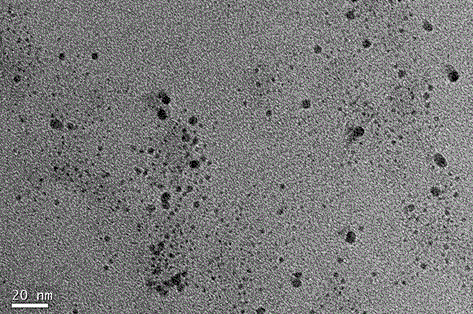

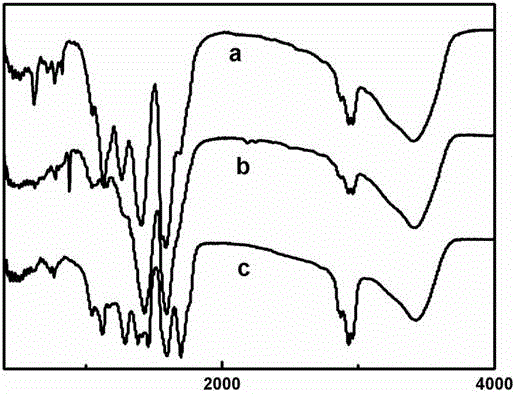

Image

Examples

Embodiment 1

[0027] Add ultra-fine graphite powder into 200 ml of distilled water, stir evenly, and then filter with ultrasonic treatment for 10 minutes, collect the graphite powder on the filter paper; disperse the above graphite powder in 200 ml of ethanol, stir well, and then ultrasonically treat for 10 minutes Suction filtration, collect the graphite powder on the filter paper, and dry at 50°C to obtain graphite powder with uniform particle size.

[0028] Take 1 gram of cleaned graphite powder and add it to 70 ml of a mixed solution of concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 5:1, stir mechanically, and control the temperature at about 110 °C. After reacting for 24 hours, the heating was stopped, and after cooling to room temperature, 430 ml of distilled water was added while stirring to dilute the reactant. Sodium hydroxide was added while stirring until the reaction was neutral.

[0029] The solution was added to a 2 liter XDA-1 macroporous resi...

Embodiment 2

[0032] Take 1 gram of cleaned graphite powder and add it to 80 ml of a mixed solution of concentrated sulfuric acid and concentrated hydrochloric acid with a volume ratio of 5:1, stir mechanically, and control the temperature at about 130 °C. After reacting for 26 hours, the heating was stopped, and after cooling to room temperature, 420 ml of distilled water was added while stirring to dilute the reactant. Sodium hydroxide was added while stirring until the reaction was neutral.

[0033] The solution solution was added to a 2 liter XDA-1 macroporous resin column and adsorbed for 4 hours. After elution with distilled water until no chloride ions are detected by silver nitrate and no sulfate ions are detected by barium chloride, the eluate is collected. Elution was performed sequentially with 1000 ml of distilled water, 1200 ml of 50% ethanol and 1800 ml of 95% ethanol.

[0034] After drying the solutions eluted with distilled water, 50% ethanol and 95% ethanol, respectively,...

Embodiment 3

[0036] Take 1 gram of cleaned graphite powder and add it to 70 ml of a mixed solution of concentrated hydrochloric acid and concentrated nitric acid with a volume ratio of 6:1, stir mechanically, and control the temperature at about 150 °C. After reacting for 28 hours, the heating was stopped, and after cooling to room temperature, 430 ml of distilled water was added while stirring to dilute the reactant. Sodium hydroxide was added while stirring until the reaction was neutral.

[0037] The solution was added to a 2 liter XDA-1 macroporous resin column and adsorbed for 6 hours. After elution with distilled water until no chloride ions can be detected by silver nitrate, start to collect the eluate. Elution was carried out successively with 1000 ml of distilled water and 1500 ml of 95% ethanol.

[0038] After drying the solutions eluted with distilled water and 95% ethanol, respectively, 0.1561 g and 0.2517 g of graphene quantum dots were obtained, with a yield of 40.78%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com