Low temperature process of preparing RE borate crystal with oxide as precursor

A technology of oxide and borate, which is applied in the field of micro/nano material preparation technology and hydrothermal synthesis, can solve the problems of high production cost, waste of organic matter, unfavorable environmental protection and rational application of resources, etc., and achieves simple operation, simple process, The effect of facilitating industrial transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: prepare lanthanum borate

[0036] Add 2.0×10 -4 mol of La 2 o 3 , 2.0-2.2×10 -4 mol of B 2 o 3 , 7ml of deionized water, and then close the reactor, transfer the two reactors to an ultrasonic generator, ultrasonically vibrate for 10 minutes, then transfer the reactors containing the mixed solution to a temperature-controlled furnace for roasting at 10°C / According to the heating rate, the reaction temperature in the furnace is controlled to be 200°C and 240°C respectively, and the constant temperature heating time is 24 hours. The reaction kettle is taken out and naturally cooled to room temperature. Washed three times with water and ethanol respectively to obtain the desired product.

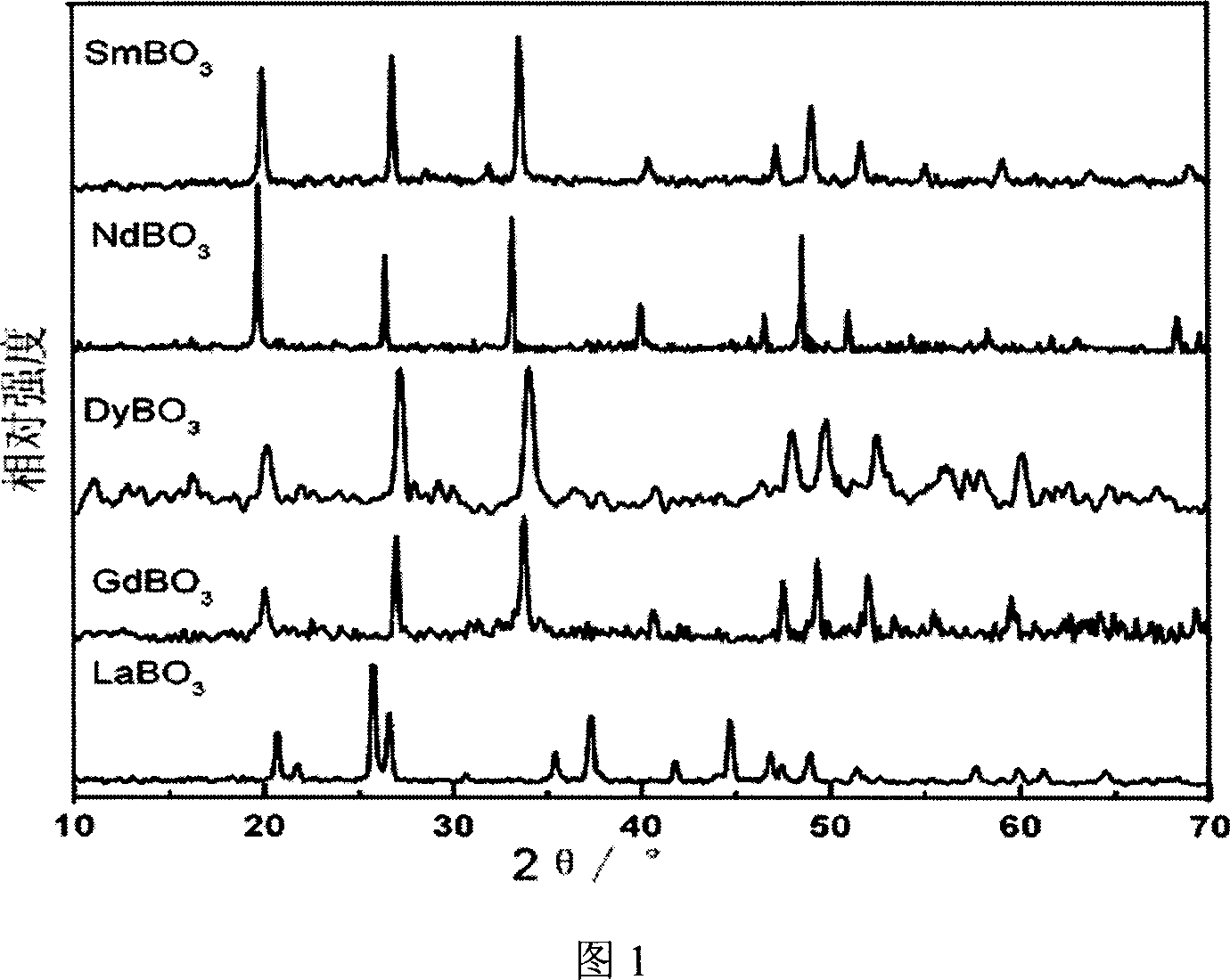

[0037] LaBO in Figure 1 3 The curve of LaBO3 X-ray powder diffraction pattern. The obtained product is consistent with the standard spectrogram of the orthorhombic lanthanum borate, and there are different degrees of broadening, indicating that the product is a nano...

Embodiment 2

[0039] Embodiment 2: prepare the borate of Sm, Gd, Dy

[0040] Add 2.0×10 -4 mol of Sm 2 o 3 、Gd 2 o 3 、Dy 2 o 3 and 2.0-2.2×10 -4 mol B 2 o 3 -3H 2 O is the raw material, 6-7mL of deionized water is used to seal the reactor, mix evenly, and then transfer the three reactors containing the mixed solution to a temperature-controlled furnace for roasting, control the reaction temperature in the furnace to 200°C, and heat at a constant temperature The time is 24 hours, take out the reaction kettle, cool naturally to room temperature, take out the precipitate obtained in the reaction kettle, and wash with deionized water and absolute ethanol alternately for 4-5 times respectively to obtain the desired product.

[0041] SmBO given in Figure 1 3 The curve is the resulting product SmBO 3 The X-ray diffraction pattern was found to be consistent with the standard pattern through retrieval. There is obvious broadening phenomenon in the spectrogram, indicating that the produc...

Embodiment 3

[0044] Embodiment 3: prepare the orthoborate of Er and Y

[0045] Add 2.0×10 -4 mol of Er 2 o 3 , Y 2 o 3 , 2.0-2.2×10 -4 mol B 2 o 3 As raw material, deionized water 7-8mL, additive o-phenanthroline 0.02 g, seal the reactor, mix evenly, then transfer the two reactors containing the mixed solution to a temperature-controlled furnace for roasting, and control the reaction in the furnace The temperature is 280°C, and the reaction time is 24 hours. Take out the reactor, let it cool down to room temperature naturally, take out the precipitates in the reactor, wash with deionized water and absolute ethanol alternately for 5-6 times respectively, and obtain the desired product.

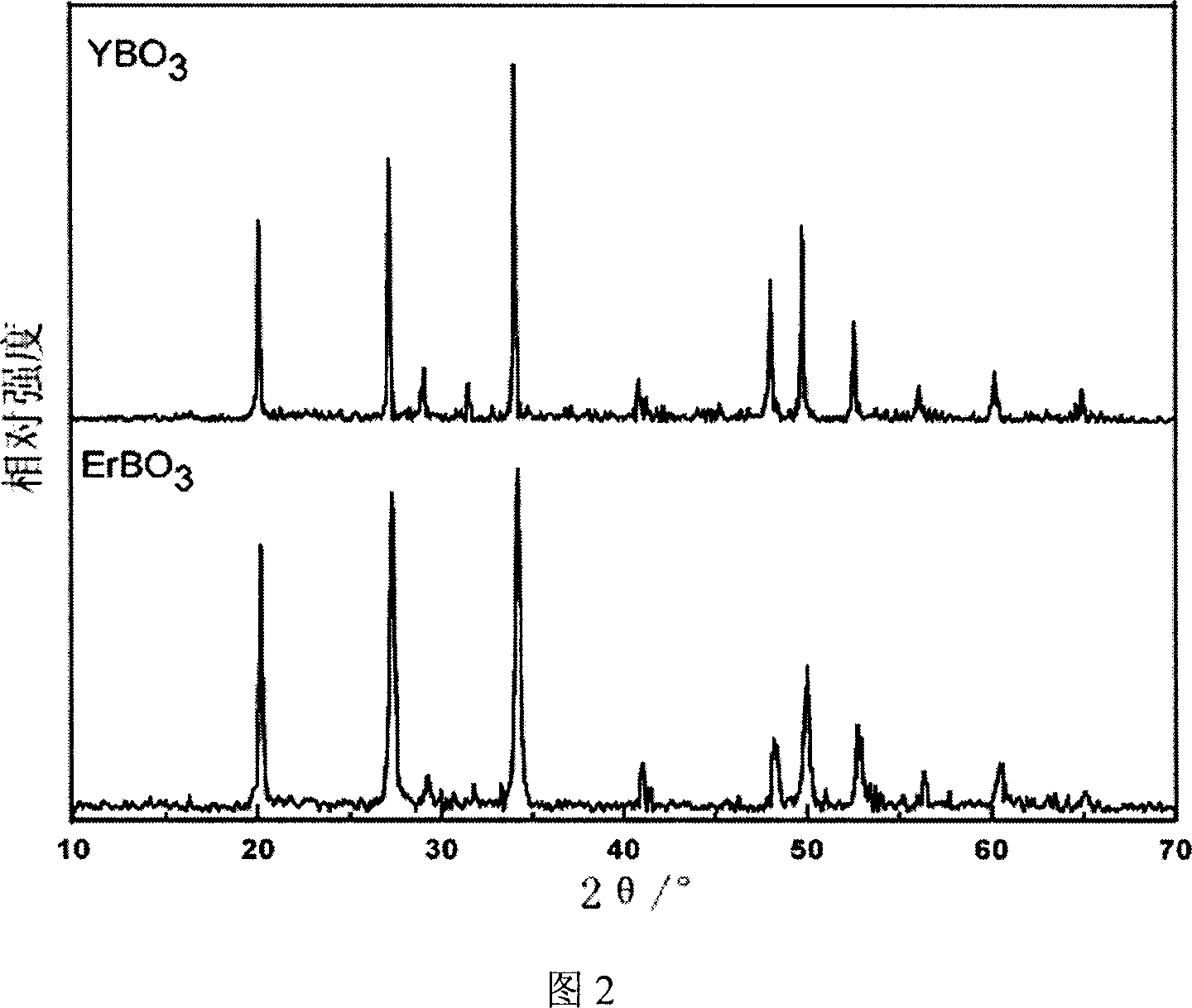

[0046] Figure 2 shows the ErBO 3 The curve for ErBO 3 The X-ray diffraction pattern of X-ray diffraction pattern, found that product is consistent with erbium borate standard pattern pattern through retrieval, and pattern pattern appears obvious broadening phenomenon, and ErBO given in Fig. 7 (A) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com