Preparation and application of biomass carbon nanosphere cluster material

A biomass carbon and nanosphere technology, which can be applied to fuel cell-type half-cells and secondary battery-type half cells, electrical components, battery electrodes, etc. Effects of stable cycling performance, mild reaction conditions, and excellent charge-discharge reversibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] Preparation of lithium-air battery positive electrode: the biomass carbon nanosphere cluster material prepared in the examples and the binder (polyvinylidene fluoride, PVDF) are mixed and then added with a diluent (N-methylpyrrolidone, NMP) Slurry, then the slurry is coated on the current collector (carbon paper), then placed in 80 ℃ vacuum drying oven to dry, after cutting into pieces, to obtain the positive electrode sheet of lithium-air battery; wherein, carbon material: binder The mass ratio is 4:1.

[0057] Lithium-air battery assembly: the positive electrode sheet of the lithium-air battery prepared in the example is used as the positive electrode, metal lithium is used as the negative electrode, commercial (GF / D, Whatman) glass fiber membrane is used as the diaphragm, tetraethylene glycol dimethyl ether / bistrifluoro Lithium methanesulfonylimide is used as the electrolyte, and a Swagelok structure battery is assembled in an argon-filled glove phase; then the assem...

Embodiment 1

[0059] Step 1. Mix medical absorbent cotton (cellulose content close to 100%) and phosphoric acid solution (mass fraction 85%) according to the ratio of 1g:10mL, and let it stand for soaking and hydrolysis for 12 hours;

[0060] Step 2. Pre-carbonize the soaked and hydrolyzed mixture in an air atmosphere at 250°C for 5 hours;

[0061] Step 3. Put the pre-carbonized mixture into a tube furnace, heat up to 600°C at a heating rate of 10°C / min under an atmosphere of high-purity nitrogen (99.999%), and cool down naturally after carbonizing at 600°C for 1 hour;

[0062] Step 4. The carbonized material was washed and filtered with deionized water several times until the pH value of the filtrate was neutral, and the washed material was heated and dried in an oven at 80° C. for 24 hours to obtain a biomass carbon nanosphere cluster material.

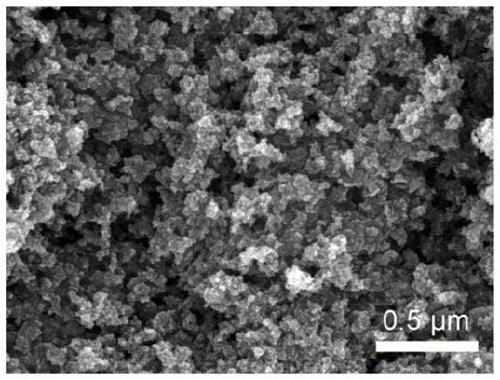

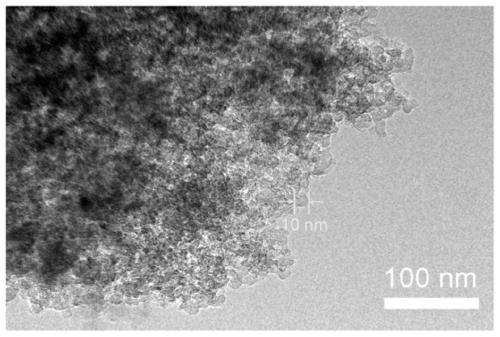

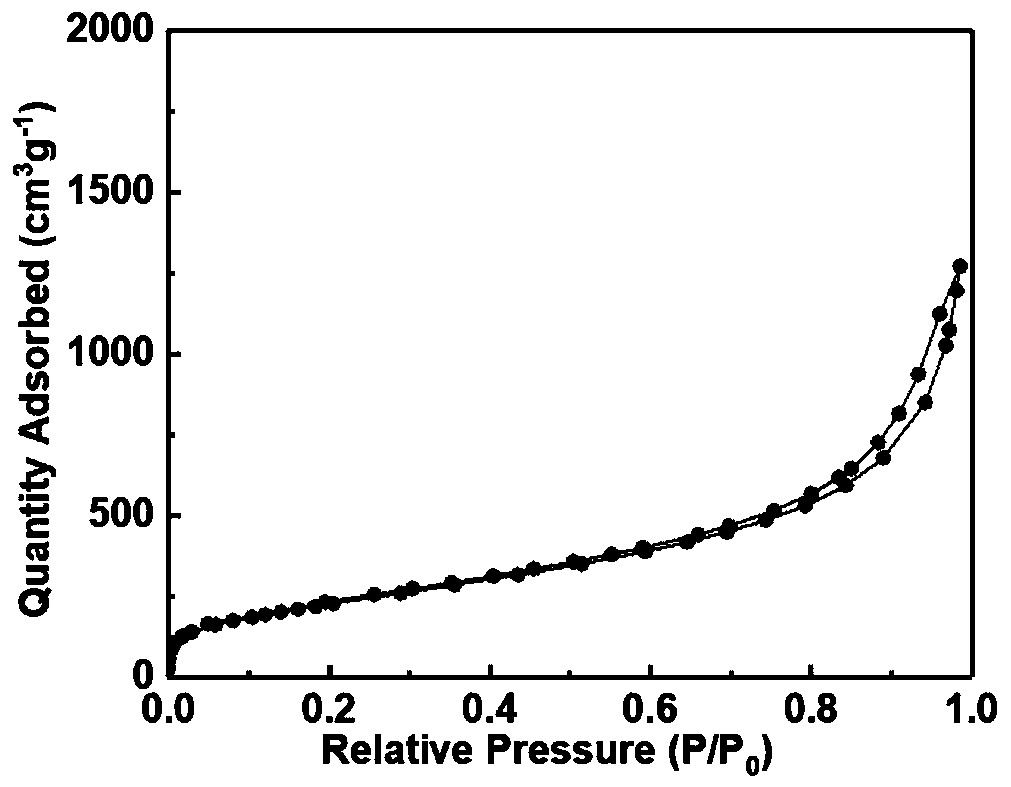

[0063] Depend on figure 1 with figure 2 It can be seen that the prepared biomass carbon nanosphere cluster material is a cluster structure fo...

Embodiment 2

[0068] Step 1. Dry and pulverize the white spongy part of pomelo peel and mix it with phosphoric acid solution (mass fraction 85%) according to the ratio of 1g:10mL, let it stand and soak for 24h to hydrolyze;

[0069] Step 2. Pre-carbonize the soaked and hydrolyzed mixture in an air atmosphere at 250°C for 4 hours;

[0070] Step 3. Put the pre-carbonized mixture into a tube furnace, heat up to 600°C at a heating rate of 10°C / min under a high-purity nitrogen atmosphere (99.999%), and cool down naturally after carbonizing at 600°C for 1 hour;

[0071] Step 4. The carbonized material was washed and filtered with deionized water several times until the pH value of the filtrate was neutral, and the washed material was heated and dried in an oven at 80° C. for 24 hours to obtain a biomass carbon nanosphere cluster material.

[0072] Depend on Figure 8 It can be seen that the biomass carbon nanosphere cluster material prepared in this example is a cluster structure formed by stack...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com