Method for preparing fiberized soybean protein gel under acidic condition

A technology of soybean protein gel and acidic conditions, applied in the field of preparing fibrillated soybean protein gel, can solve the problems of high energy consumption and high equipment maintenance cost, and achieve the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

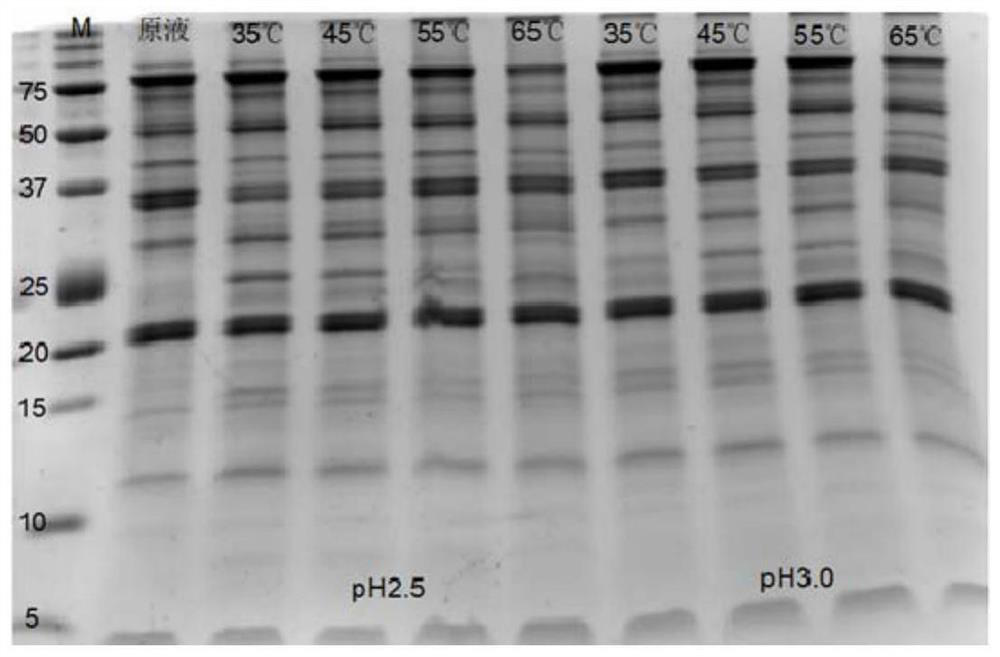

[0027] The influence of embodiment 1pH and temperature on soybean protein hydrolysis

[0028] (1) Preparation of aqueous soybean extract: 320 g of soybeans were washed, added with 3000 mL of deionized water, and soaked at 4° C. for 18 h at low temperature. Take out and wash the beans, add deionized water to a total weight of 3200g, grind for 2 minutes, and filter to obtain soybean water extract and bean dregs;

[0029] (2) Preparation of soybean protein liquid: take the soybean water extract prepared in step (1) and centrifuge at 8000 rpm for 10 min, filter the upper layer of grease with gauze to obtain soybean protein liquid;

[0030] (3) Preparation of the gel: Divide the protein solution into 9 parts, of which 4 parts were adjusted to pH 2.5 with phosphoric acid, 4 parts were adjusted to pH 3.0 with phosphoric acid, and the other 1 part was used as a control;

[0031] The protein solutions with two pHs were divided into 4 parts and put into the enzymolyzer, and heated at c...

Embodiment 2

[0034] The protein content determination of embodiment 2 soybean protein liquid

[0035] (1) Preparation of aqueous soybean extract: 160 g of soybeans were washed, added with 1600 mL of deionized water, and soaked at 4° C. for 18 h at low temperature. Take out and wash the beans, add deionized water to a total weight of 1600g, grind for 2 minutes, and filter to obtain soybean water extract and bean dregs;

[0036] (2) Preparation of soybean protein liquid: the aqueous soybean extract prepared in step (1) was centrifuged at 8000 rpm for 10 min, and the upper layer of oil was filtered with gauze to obtain soybean protein liquid.

[0037] The solid content of the protein solution obtained under this method was determined to be 5.643% by oven method. The protein content was determined to be 2.68% by Kjeldahl method.

Embodiment 3

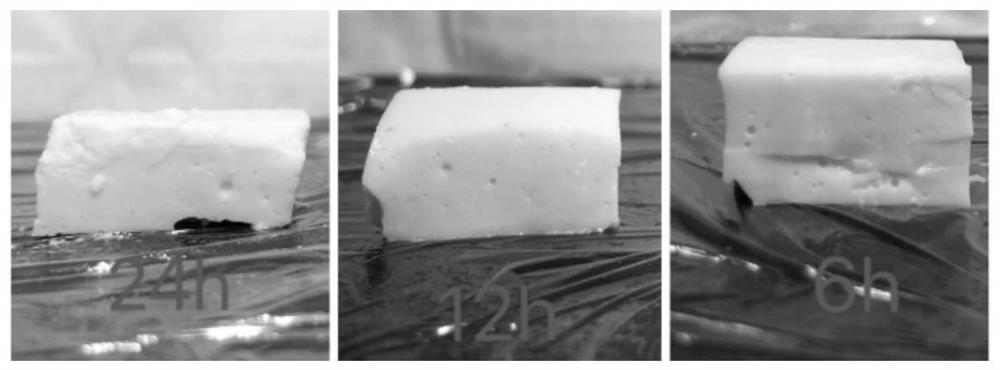

[0038] The influence of embodiment 3 supernatant content on gel

[0039] (1) Preparation of aqueous soybean extract: 160 g of soybeans were washed, added with 1600 mL of deionized water, and soaked at 4° C. for 18 h at low temperature. Take out and wash the beans, add deionized water to a total weight of 1600g, grind for 2 minutes, and filter to obtain soybean water extract and bean dregs;

[0040] (2) Preparation of soybean protein liquid: take the soybean water extract prepared in step (1) and centrifuge at 8000 rpm for 10 min, filter the upper layer of grease with gauze to obtain soybean protein liquid;

[0041] (3) Preparation of protein solution system: adjust the pH to 4.5 with phosphoric acid, centrifuge at 2000rpm for 10 minutes, and separate layers to obtain supernatant and precipitate; divide the precipitate and supernatant into two parts, and one part removes 70% of the total weight Supernatant, so that the protein concentration was 8.05%; one portion of the supern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com