Preparation method and application of ruthenium-carbene catalyst

A catalyst and carbene complex technology, applied in the field of preparation of ruthenium carbene complexes, can solve the problems of limited application scope, many synthesis steps, complicated processes, etc., and achieve the effects of simple equipment and process, high activity, and rational utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 A kind of preparation method of ruthenium carbene complex, described ruthenium carbene complex is two-triphenylphosphine-phenylethylene ether-dichlororuthenium complex, and its chemical formula is (PCy 3 ) 2 Cl 2 Ru=CHCH 2 OPh, the conditions and steps of the preparation method of described ruthenium carbene complex are as follows:

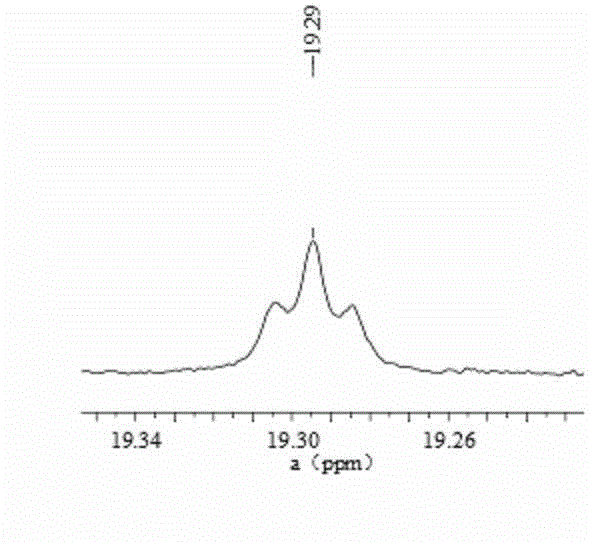

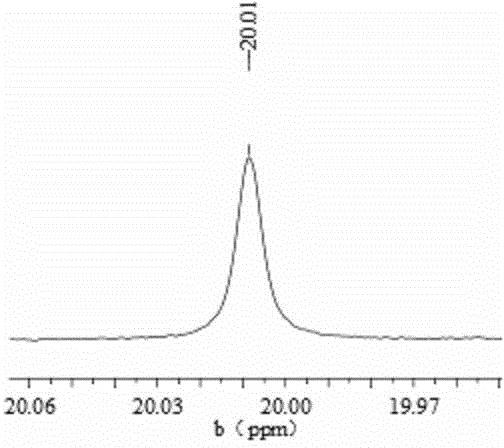

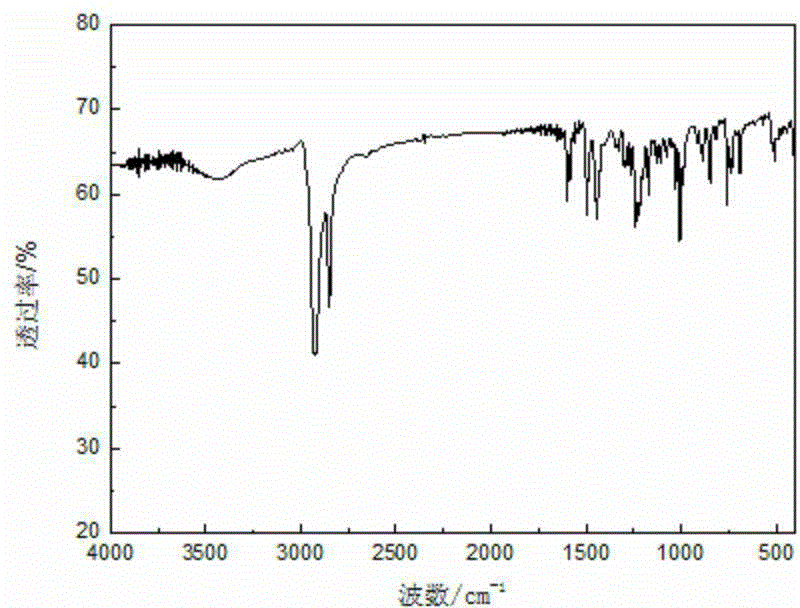

[0027] (one) Allyl phenyl ether C 9 h 10 Preparation of O: Add 50 mL of solvent acetone to the three-necked flask, then add 4.71 g (0.05 mol) of phenol, 7.26 g (0.06 mol) of 3-bromopropene and 7.60 anhydrous potassium carbonate in sequence at a molar ratio of 1:1.2:1.1 g (0.055 mol), the reaction temperature is 50 ℃, the reaction time is 6 h, and the reaction is carried out under the condition of reflux. After the reaction is completed, allyl phenyl ether C is obtained by suction filtration and vacuum distillation 9 h 10 O is 6.37 g, and the productive rate of the product obtained by the reaction is 95%, and the product ...

Embodiment 2

[0032] Example 2 A kind of preparation method of ruthenium carbene complex, described ruthenium carbene complex is two-triphenylphosphine-phenylethylene ether-dichlororuthenium complex, and its chemical formula is (PCy 3 ) 2 Cl 2 Ru=CHCH 2 Oph, the conditions and steps of the preparation method of the described ruthenium carbene complex are as follows:

[0033] (one) Allyl phenyl ether C 9 h 10 Preparation of O: Add 50 mL of solvent acetone into the three-necked flask, then add 4.71 g (0.05 mol) of phenol, 6.05 g (0.05 mol) of 3-bromopropene and 6.91 g of anhydrous potassium carbonate in sequence at a molar ratio of 1:1:1. g (0.05 mol), the reaction temperature is 40 ℃, the reaction time is 7 h, and the reaction is carried out under the condition of reflux. After the reaction is completed, allyl phenyl ether C is obtained by suction filtration and vacuum distillation 9 h 10 O was 6.00 g, and the yield of the product obtained by the reaction was 90%.

[0034] (two)...

Embodiment 3

[0038] Example 3 A kind of preparation method of ruthenium carbene complex, described ruthenium carbene complex is two-triphenylphosphine-phenylethylene ether-dichlororuthenium complex, and its chemical formula is (PCy 3 ) 2 Cl 2 Ru=CHCH 2 Oph, the conditions and steps of the preparation method of the described ruthenium carbene complex are as follows:

[0039] (one) Allyl phenyl ether C 9 h 10 Preparation of O: Add 50 mL of solvent acetone into a three-necked flask, then add 4.71 g (0.05 mol) of phenol, 12.10 g (0.1 mol) of 3-bromopropene and 13.82 anhydrous potassium carbonate in sequence at a molar ratio of 1:2:2 g (0.1 mol), the reaction temperature is 60 °C, the reaction time is 4 h, and the reaction is carried out under the condition of reflux. After the reaction is completed, allyl phenyl ether C is obtained by suction filtration and vacuum distillation 9 h 10 O was 5.90 g, and the yield of the product obtained by the reaction was 88%.

[0040] (two) Prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com