Yeast crushing equipment and method for preparing yeast powder

A technology of koji powder and equipment, which is applied in the field of brewing, can solve the problems that the crushed quality of the crusher cannot be controlled in real time, has no practical operability, and koji powder cannot be transported, and achieves real-time monitoring of the crushing quality, flexible layout, and unparalleled effect on pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

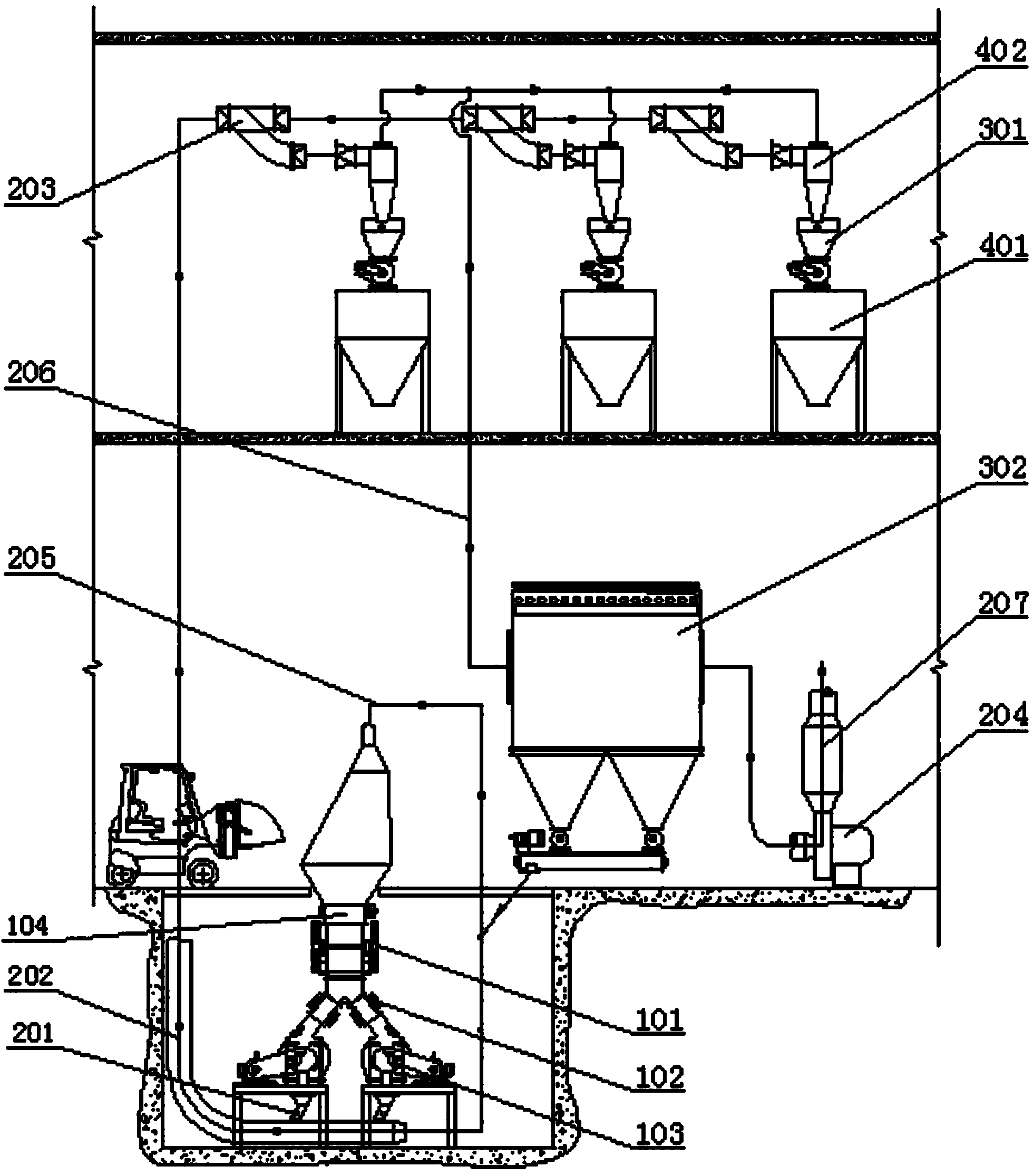

[0036] Embodiment one: if figure 1 As shown, a kind of koji powder equipment according to the present invention includes a wind power conveying system and a crushing mechanism connected to the wind power conveying system, a koji powder buffer storehouse 402 and a bag filter 302, and the wind power conveying system includes an induced draft fan 204, a feeding Air duct 202, dust suction air duct 205, dust air duct 206 and clean air duct 207, wherein one end of feeding air duct 202 is connected with a pulverizing mechanism, and the pulverizing mechanism is connected in parallel by two hammer fine crushers 103 to a The claw crusher 101 is connected to each other, and the other end of the feeding air pipe 202 is communicated with three koji powder buffer bins 402 through three three-way switching valves 203 respectively, and the upper end of each koji powder buffer bin 402 is connected with the dust air The pipe 206 is connected, and a cyclone dust collector 301 is arranged at the ...

Embodiment 2

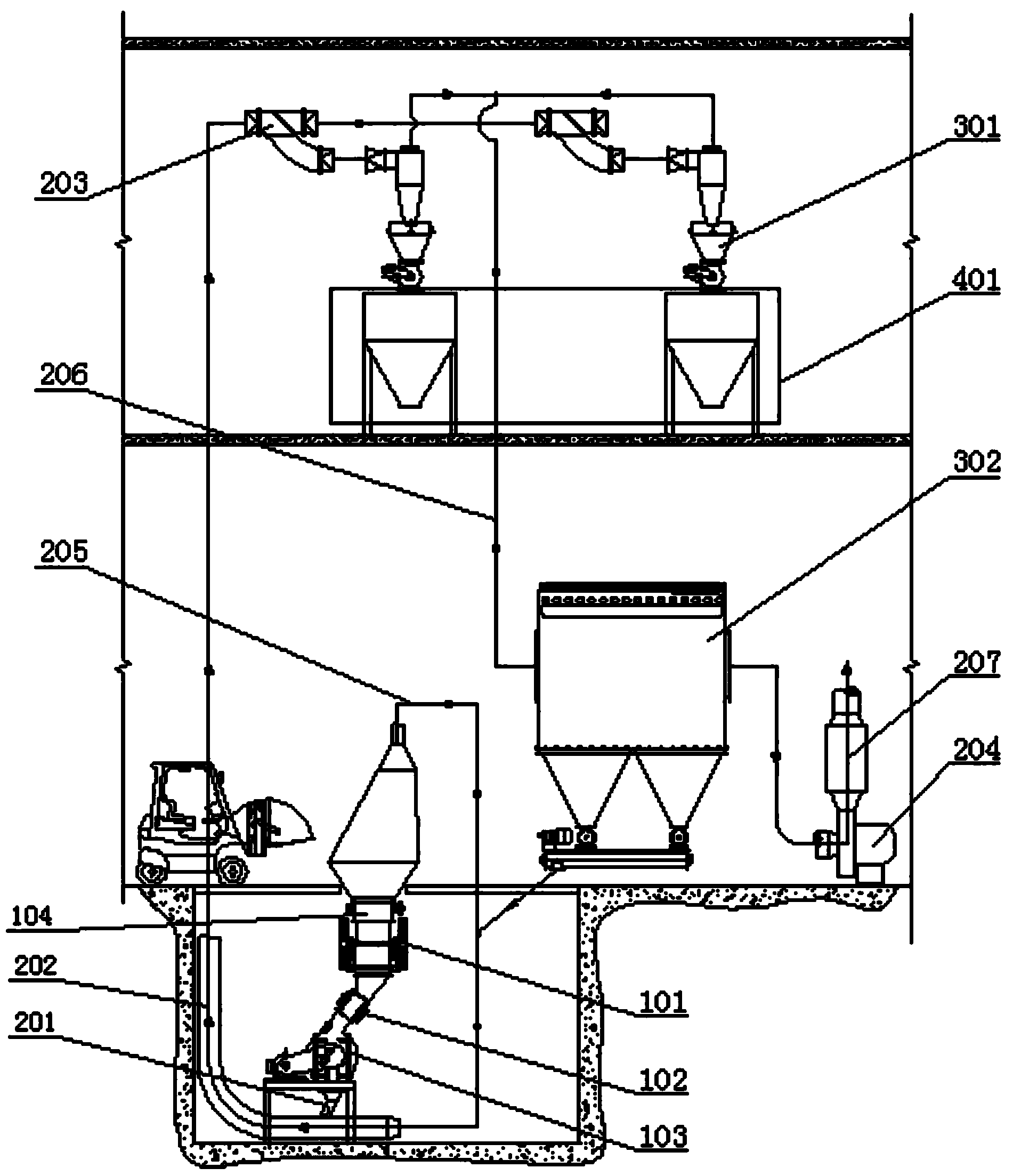

[0041] Embodiment two: if figure 2 As shown, a kind of koji powder equipment according to the present invention includes a wind power conveying system and a crushing mechanism connected to the wind power conveying system, a koji powder buffer storehouse 402 and a bag filter 302, and the wind power conveying system includes an induced draft fan 204, a feeding Air duct 202, dust suction duct 205, dust air duct 206 and clean air duct 207, wherein one end of the feeding duct 202 is connected to a pulverizing mechanism, and the pulverizing mechanism consists of a hammer fine crusher 103 and a jaw crusher. type crusher 101 in series, the other end of the feeding air pipe 202 communicates with two koji powder buffer bins 402 through two three-way switching valves 203 respectively, and the upper end of each koji powder buffer bin 402 is connected to the dust air duct 206 Connected, each koji powder buffer storehouse 402 lower end is all provided with cyclone dust collector 301, and k...

Embodiment 3

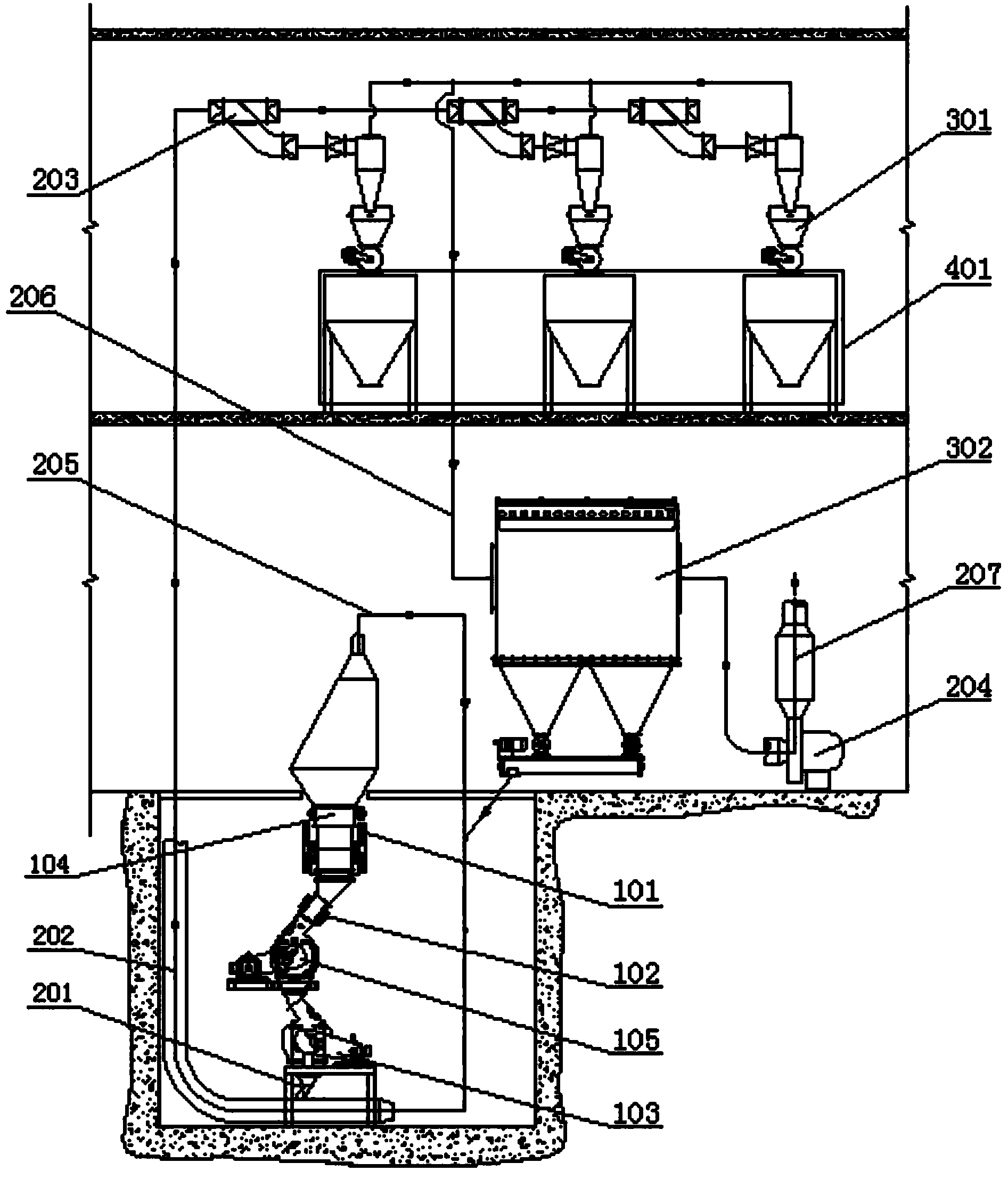

[0046] Embodiment three: as image 3 As shown, a kind of koji powder equipment according to the present invention includes a wind power conveying system and a crushing mechanism connected to the wind power conveying system, a koji powder buffer storehouse 402 and a bag filter 302, and the wind power conveying system includes an induced draft fan 204, a feeding Air duct 202, dust suction duct 205, dust air duct 206 and clean air duct 207, wherein one end of the feeding duct 202 is connected to a crushing mechanism, and the crushing mechanism consists of a claw crusher 101 and two hammer blades The fine crusher 103 is connected in series, and the other end of the feeding air pipe 202 is connected to three koji powder buffer bins 402 through three three-way switching valves 203 respectively, and the upper end of each koji powder buffer bin 402 is connected to the dust air duct 206. Connected, each koji powder buffer storehouse 402 lower end is all provided with cyclone dust colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com