Planetary flour mill

A pulverizer and planetary technology, which is applied in the field of planetary pulverizers, can solve the problems of low effective power and high energy consumption, and achieve the effects of small footprint, low energy consumption and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

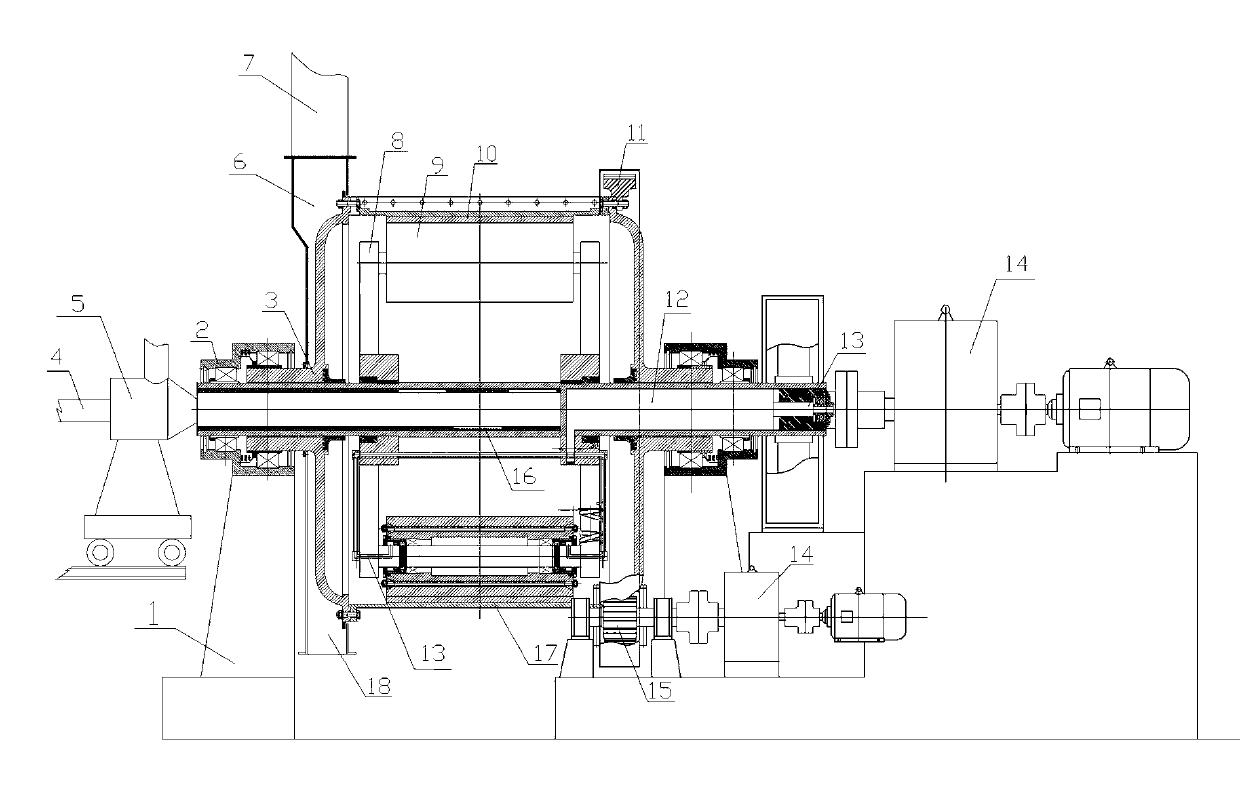

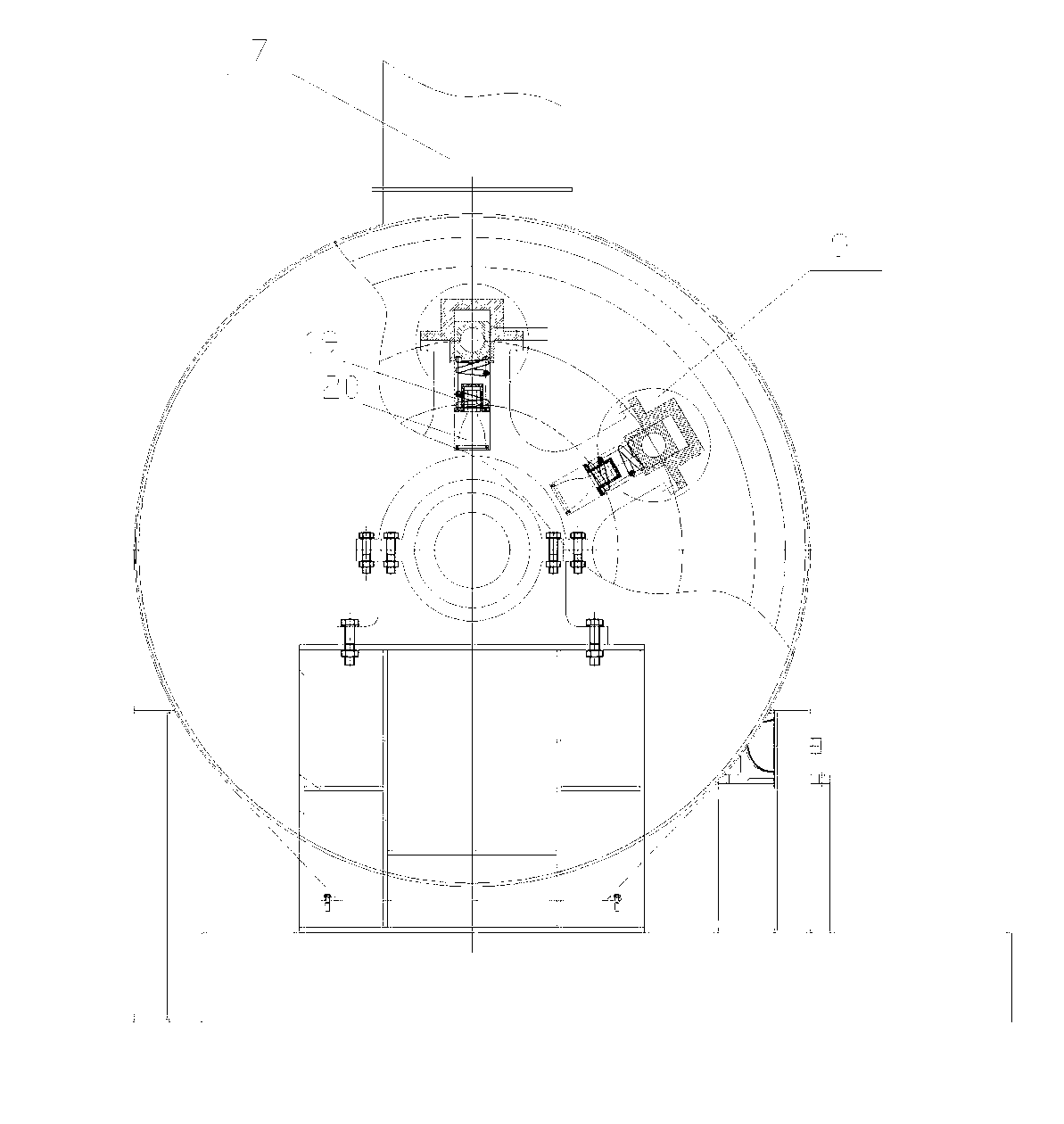

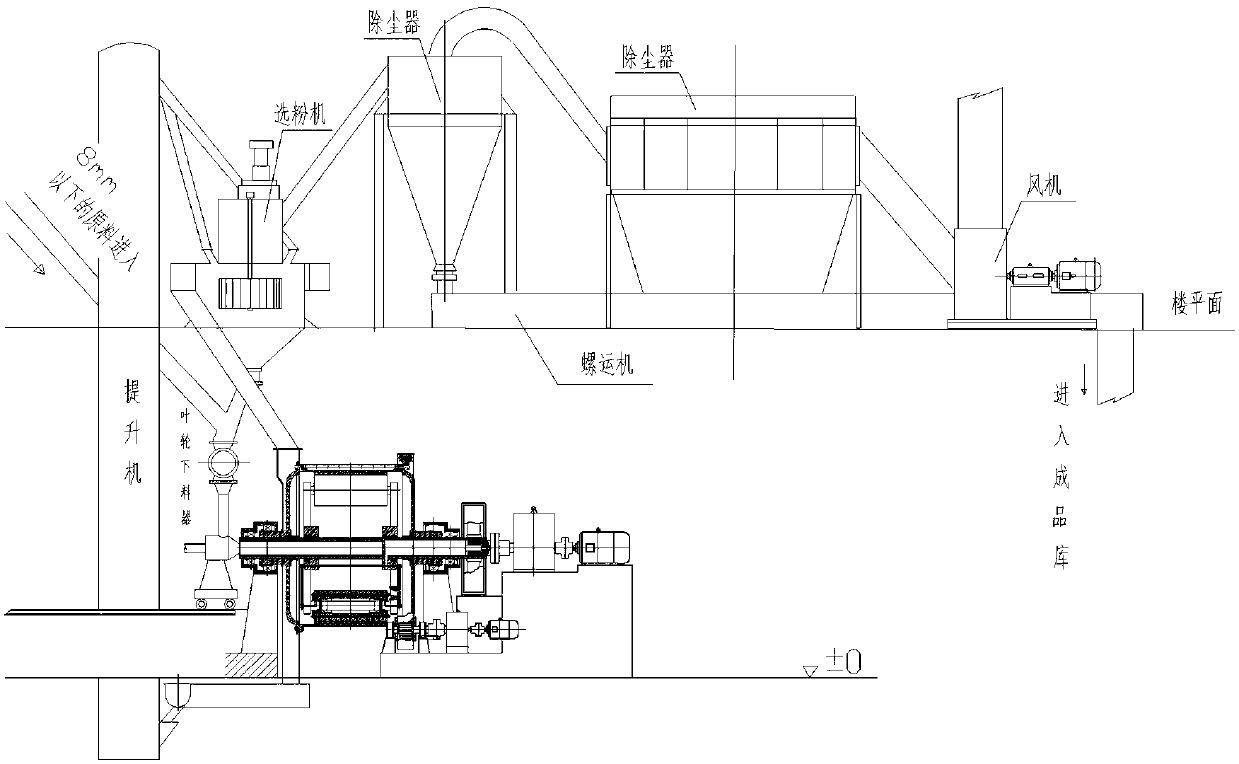

[0011] Introduce the present invention below in conjunction with accompanying drawing and embodiment:

[0012] With reference to the accompanying drawings, a bearing seat 2 is installed on the machine shaft 1 to support the hollow shaft 3 on the cylinder 17. The small gear 15 on the reducer 14 drives the large gear 11 on the cylinder to run at a slow speed, and the inner wall of the cylinder is viscous. There is a wear-resistant liner 10, a main shaft 12 installed in the center of the two hollow shafts, a planetary support 8 is fastened on the main shaft, and a crushing roller 9 is installed around the planetary support, and the crushing roller is tightly pressed against the wear-resistant The plate and the cylinder run in the opposite direction, and the pressure of the crushing roller in the cylinder is adjusted by the spring 19 and the pressure regulator 20 to adapt to the grinding effect of different materials. The feature of the present invention is to implement thin mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com