Movable shovel type potato excavator

A potato and excavator technology, applied in excavators, excavator harvesters, harvesters, etc., can solve the problems of insignificant crushing and loosening effects, large power consumption, and high separation pressure of soil and potatoes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

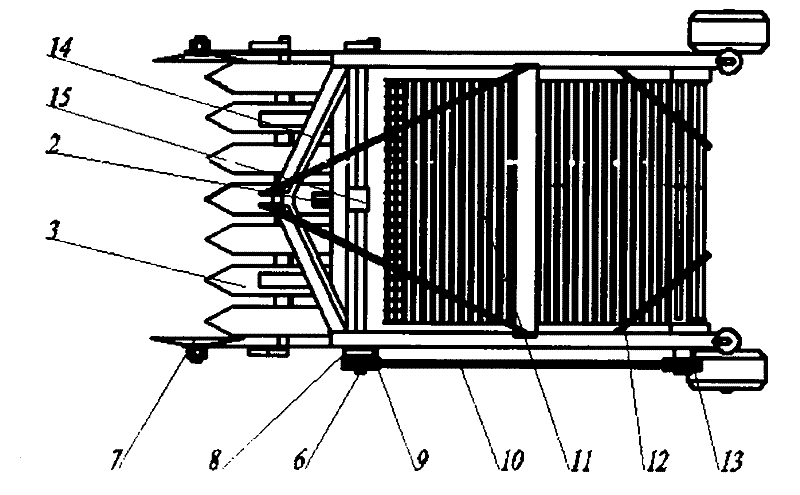

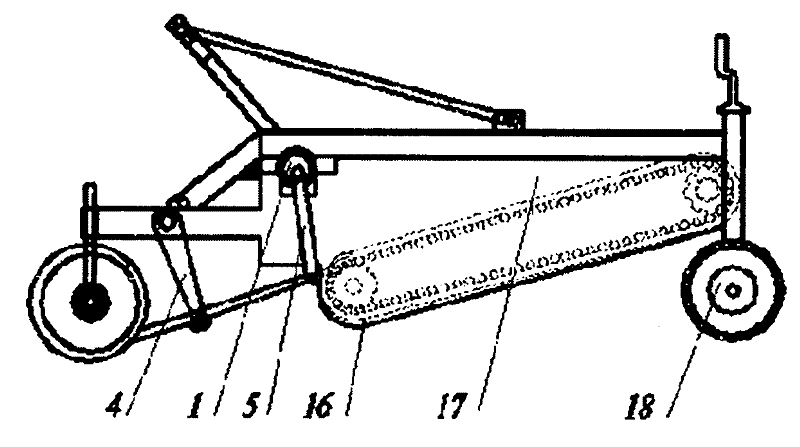

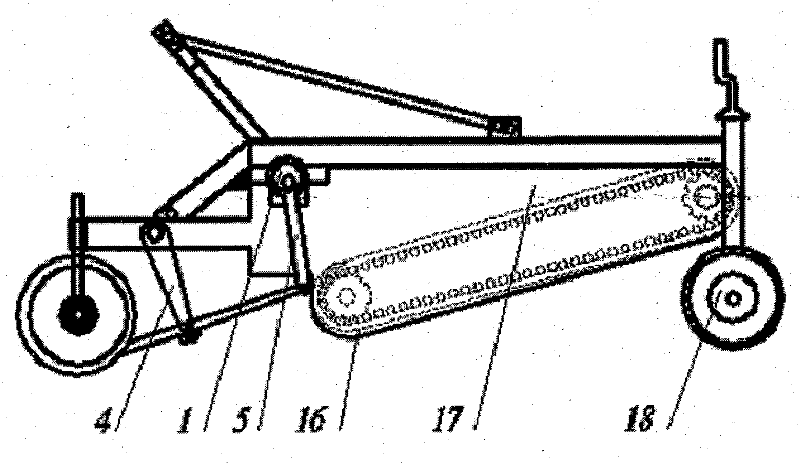

[0009] Embodiment 1, see figure, moving shovel type potato excavator, comprises eccentric wheel (1), power take-off shaft (2), digging shovel (3), connecting frame rod (4), connecting rod (5), gearbox output Shaft (6), soil cutting disc (7), connecting rod (8), driving pulley (9), belt (10), lifting chain sieve (11), gathering potato plate (12), driven pulley (13 ), frame (14), gearbox (15), baffle plate (16), rubber skin (17), ground wheel (18) etc. constitute. The rear end of the digging shovel (3) is connected with the connecting rod (5) of the vibration mechanism, and the connecting rod (5) is set on the eccentric wheel (1), and the eccentric wheel (1) passes through the power output shaft (2) through the gearbox ( 15) Driven by the outgoing power shaft (6), the rotary motion of the eccentric wheel (1) is realized; the front end of the excavating shovel is connected with the connecting rod (4), so that the excavating shovel (3) is driven by the rotation of the eccentric wh...

Embodiment 2

[0011] Embodiment 2, see figure, the moving shovel type potato excavator is mainly carried out excavating work by the combination mode that the moving shovel mechanism and the lifting chain sieve type separation mechanism combine. The moving shovel mechanism is composed of an eccentric wheel, a connecting rod, a connecting rod and an excavating shovel. The lifting chain sieve type separation mechanism is composed of cast rubber drive wheel, rod chain, baffle, baffle skin and potato board. The reciprocating motion of the shovel breaks up the earth and potato diggings, reduces the traction resistance and increases the crushability of the soil. The soil cutting disc installed at the front mainly cuts off weeds, potato stems and soil clods. After the shovel lifts the soil to the bottom of the lifting chain sieve, the soil and potatoes are separated under the conveying action of the chain sieve, and the small pieces of soil fall through the gap between the chain bars, and the larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com