Thermocompressor

A technology of injectors and steam nozzles, applied in jet pumps, machines/engines, non-displacement pumps, etc., can solve problems such as inability to obtain pump efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

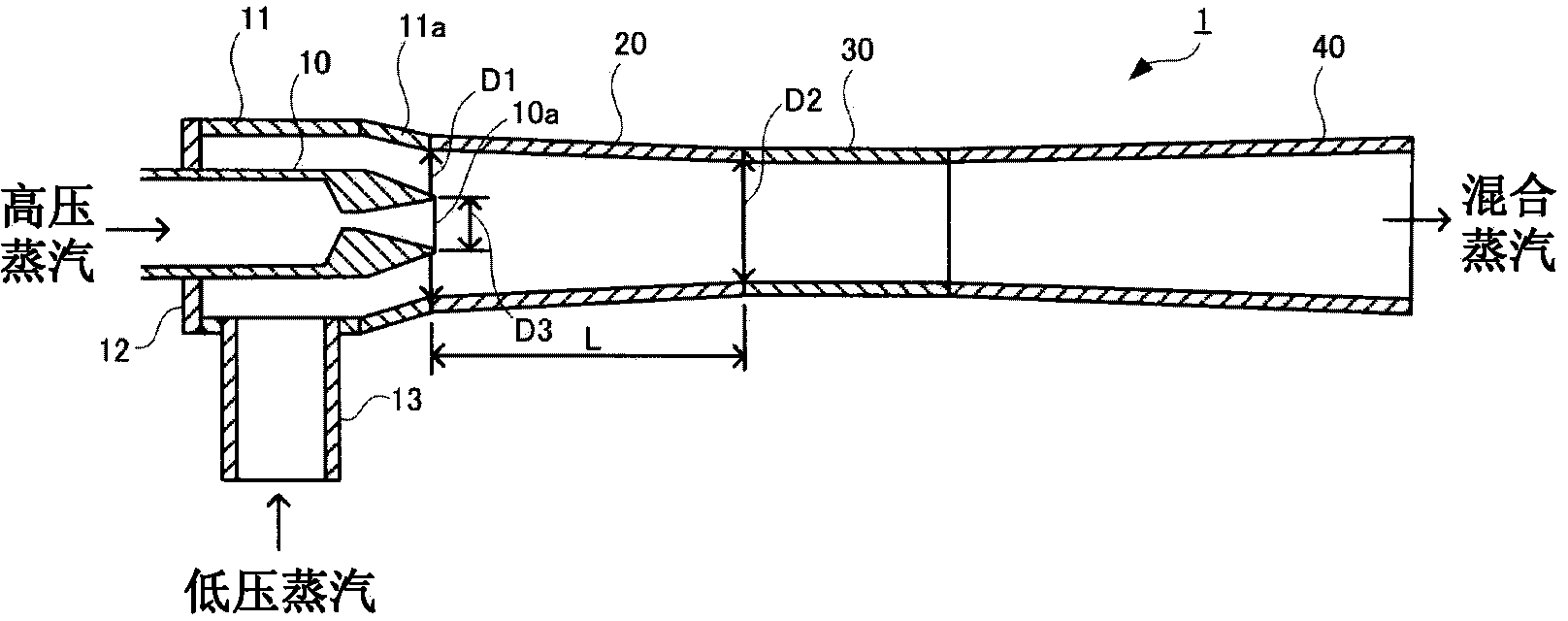

[0032] Hereinafter, one embodiment of the present invention will be described with reference to the drawings. figure 1 It is a schematic configuration diagram of a steam ejector according to an embodiment of the present invention. Such as figure 1 As shown, the steam ejector 1 is constituted by sequentially connecting a support member 11 , a mixing chamber 20 , a throat member 30 and a diffuser 40 .

[0033] The support member 11 is formed in a cylindrical shape, one end thereof is closed by an end plate 12 , and the other end thereof is connected to one end of the mixing chamber 20 . Inside the support member 11 , the tip portion of the steam nozzle 10 injecting high-pressure steam extends through the center of the end plate 12 . An injection port 10 a is formed at the tip of the steam nozzle 10 . The steam nozzle 10 is fixed to the end plate 12 so that one end surface of the mixing chamber 20 and the injection port 10 a are substantially on the same plane. An introduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com