Piezoelectric pump

A piezoelectric pump and piezoelectric element technology, applied in the field of piezoelectric pumps, can solve the problems of inability to increase discharge pressure, drop in discharge pressure, and inability to discharge fluid reliably, and achieve simple structure, high discharge pressure, and good tracking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

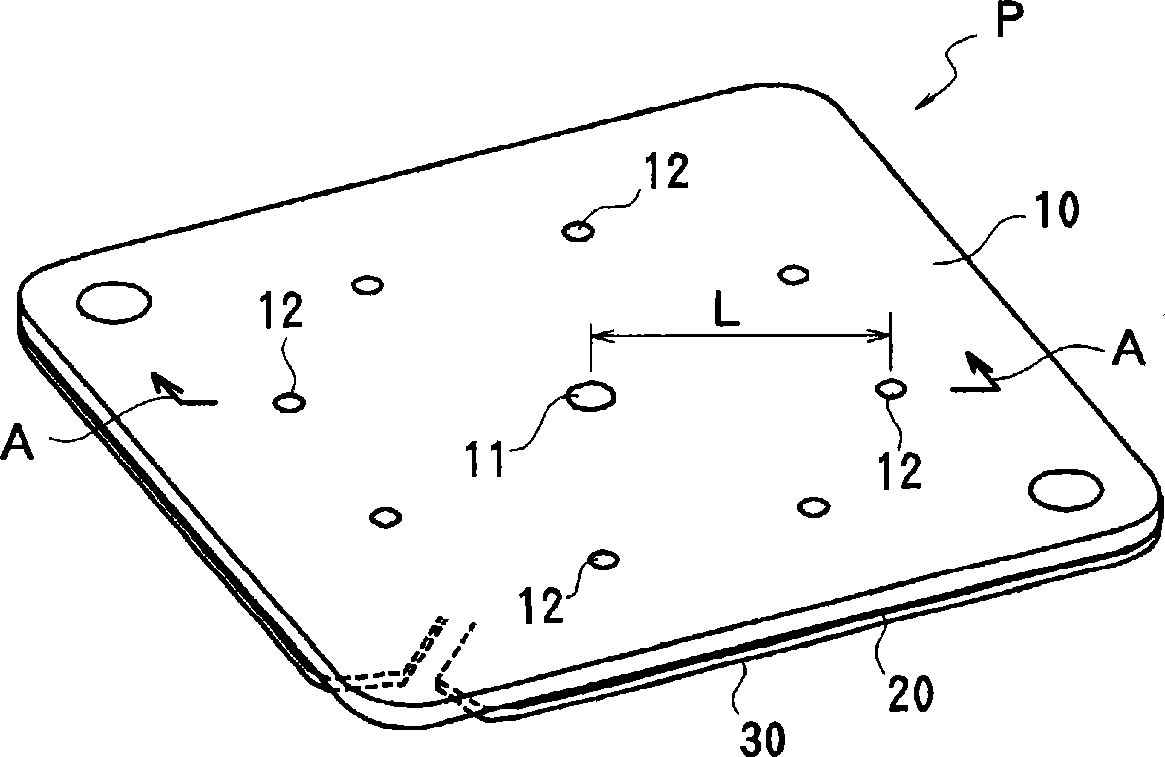

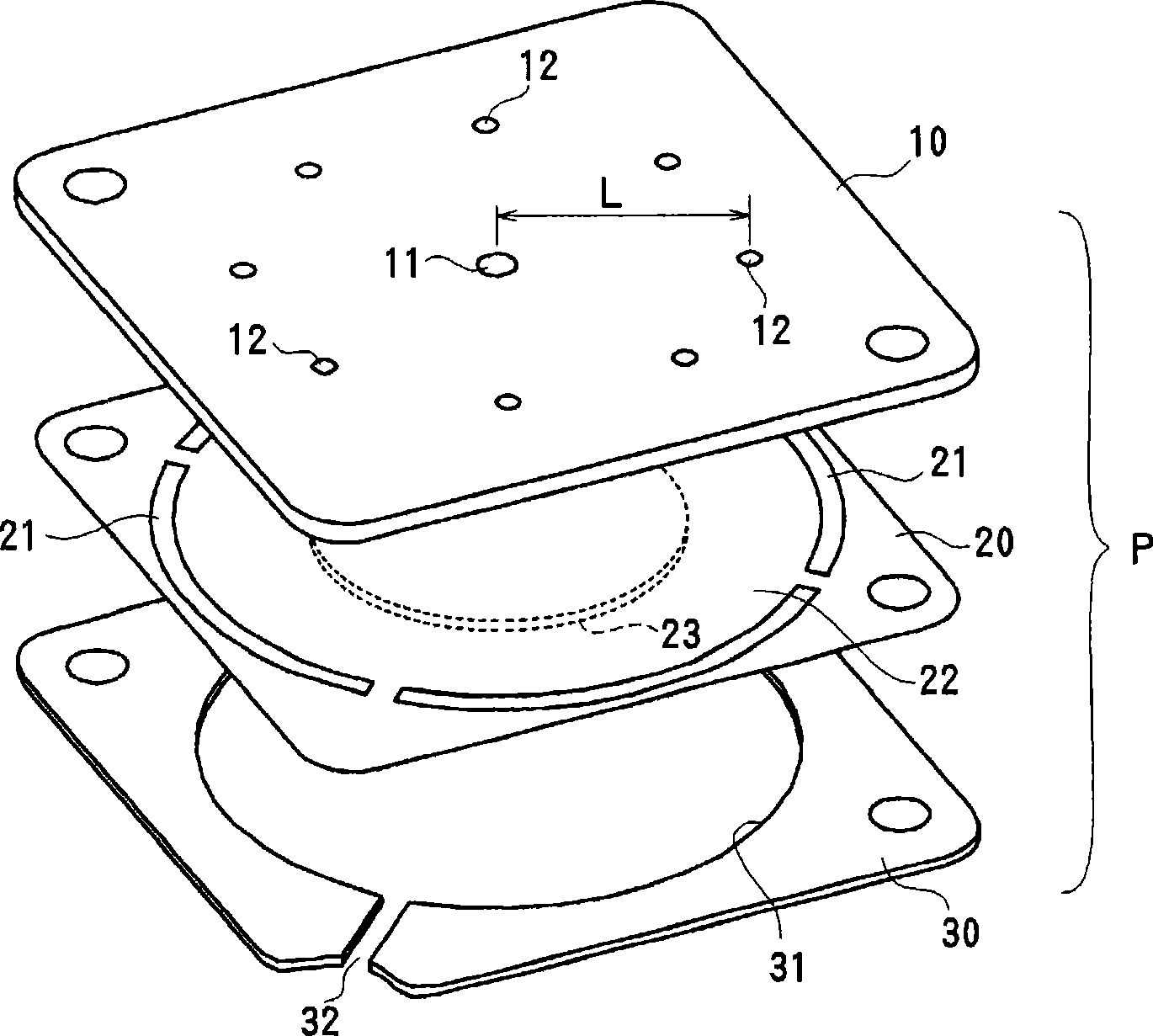

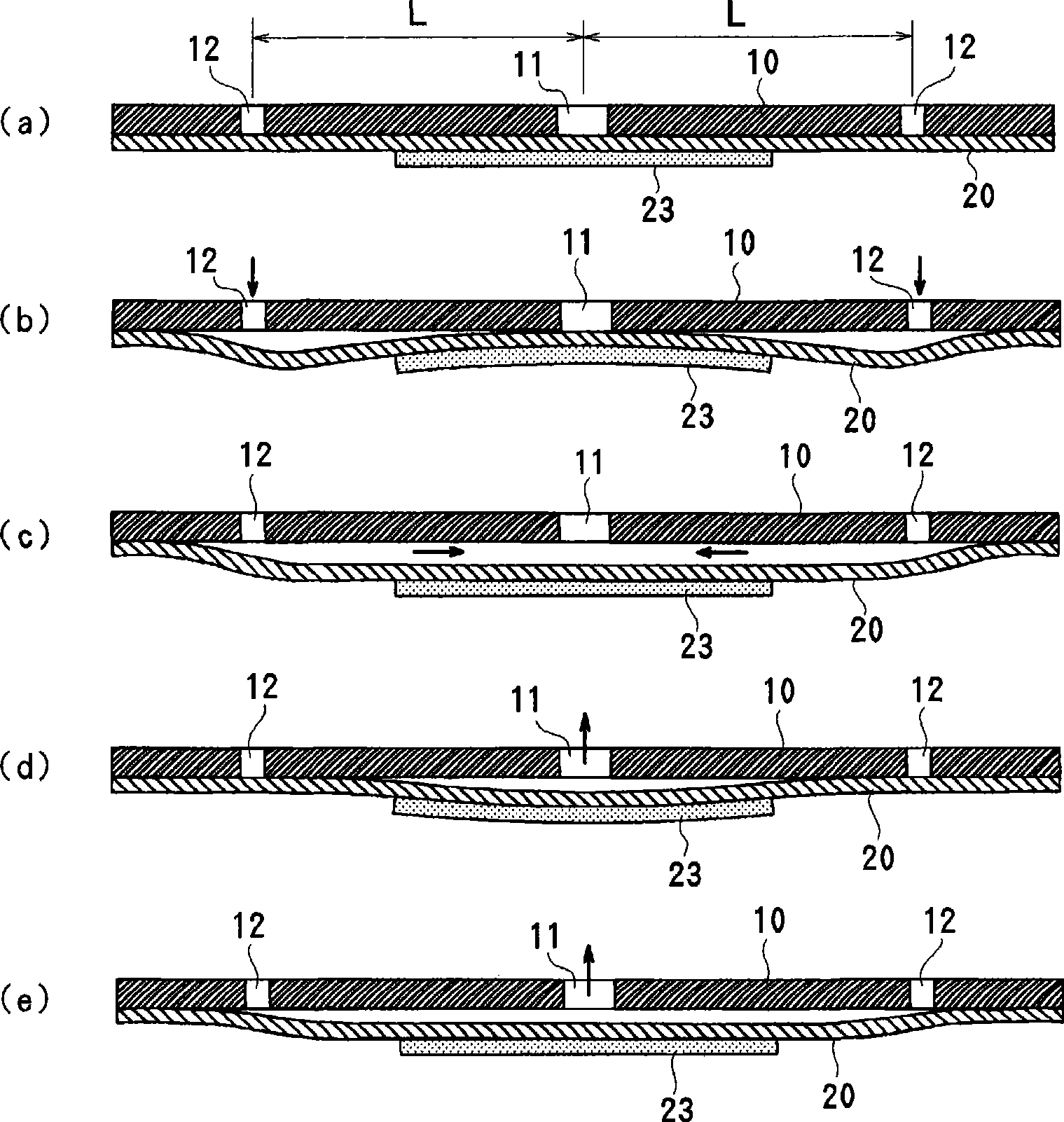

[0037] Figure 1 ~ Figure 3 A first embodiment of a piezoelectric pump is shown. here, figure 1 is an overall perspective view of the piezoelectric pump according to the present invention, figure 2 yes figure 1 An exploded perspective view of the piezoelectric pump shown, image 3 yes figure 1 Sectional view of line A-A.

[0038] The structure of the piezoelectric pump P of this embodiment is that the top plate 10 constituting the pump body, the diaphragm 20, and the ring-shaped pressing plate 30 are stacked in sequence, and these parts are stacked and bonded. The top plate 10 is formed in a rigid flat plate shape, a first opening 11 is formed at the center thereof, and a plurality of second openings 12 are formed on the same circumference around the first opening 11 . Here, eight second openings 12 are formed to ensure the flow rate, but the number of second openings 12 can be set arbitrarily according to the required flow rate.

[0039] The diaphragm 20 is formed of ...

Embodiment 2

[0055] Figure 5 The pump action operation in the third resonance mode of the second embodiment of the present invention is shown. For with image 3 The same parts are marked with the same reference numerals, and repeated explanations are omitted. In the first embodiment, the second opening 12 is provided on the pump body 10 , but in this embodiment, the second opening 25 is provided on the diaphragm 20 . At this time, if driven in the tertiary resonance mode, the fluid can be sucked from the second opening 25 on the back side of the piezoelectric pump and discharged from the first opening 11 on the front side. This structure is ideal as an air supply pump or a cooling pump for the fuel cell.

Embodiment 3

[0057] Figure 6 The pump action operation in the third resonance mode of the third embodiment of the present invention is shown. For with image 3 The same parts are marked with the same reference numerals, and repeated explanations are omitted. In this embodiment, a part of the pump body 10 is extended outward from the diaphragm 20 , and a groove-shaped second opening 16 extending from the inner side to the outer side of the outer peripheral portion of the diaphragm 20 is formed on the lower surface side of the extended portion 15 . The inner end of the second opening 16 is located outside the outer periphery of the piezoelectric element 23 and inner than the outer periphery fixing portion of the diaphragm 20 , and the outer end is opened from the extension portion 15 to the lower surface side. In addition, the second opening 16 does not have to be in the shape of a groove, but may be formed as an inner end opening on the outside of the piezoelectric element 23 and inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com