Self-cooling fan

A self-cooling and fan technology, applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of limited operating area, reduced user work efficiency, and increased work tasks, so as to increase the sweeping area and facilitate gas Inflow, avoid the effect of poor ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

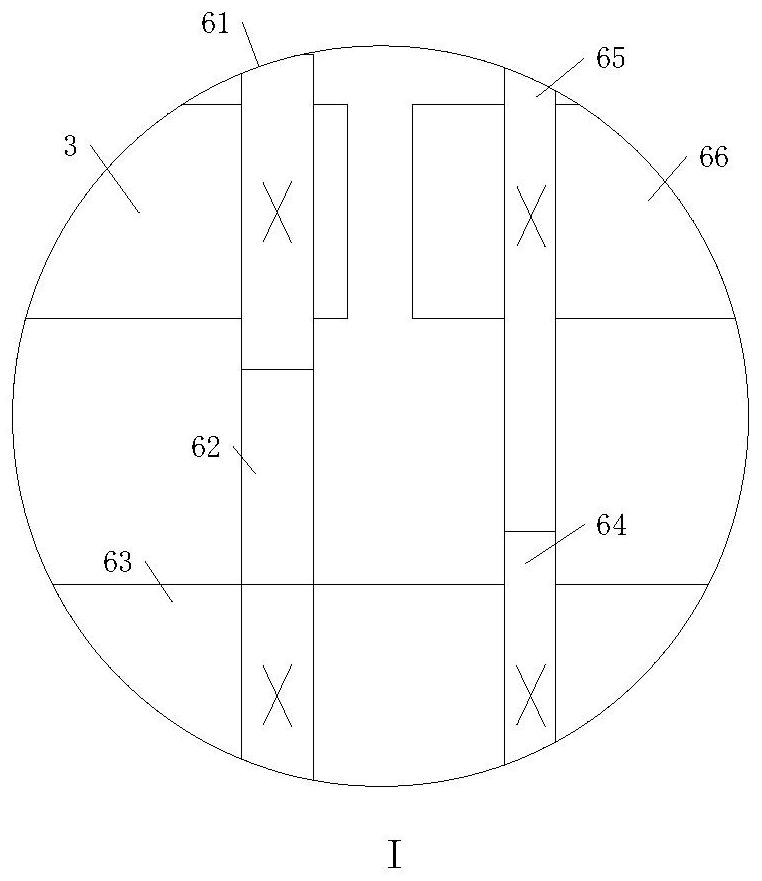

[0028] As an embodiment of the present invention, the reduction device 6 includes: A small gear 61, A large gear 62, reduction shaft 63, B small gear 64, B large gear 65 and output shaft 66, the A small gear 61 Fixedly installed on the rotating main shaft 3, the A large gear 62 is fixedly installed on the left side of the reduction shaft 63 and constitutes a gear transmission with the A small gear 61, and the two ends of the reduction shaft 63 are rotatably connected with the heat shield 18. The B small gear 64 is fixedly installed on the right side of the reduction shaft 63, the B large gear 65 is fixedly installed on the output shaft 66 and forms a gear transmission with the B small gear 64, and the left end of the output shaft 66 is in the middle of the two heat shields 18 The position is close to the right side, and the output shaft 66 is fixedly connected with the right heat shield 18 close to the middle position.

[0029] The rotating main shaft 3 rotates, driving the A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com