Resonant type piezoelectric stack pump with sliding valves

A piezoelectric stacking and resonant technology, which is applied in variable capacity pump components, pumps with flexible working elements, components of pumping devices for elastic fluids, etc., can solve problems such as hysteresis and achieve increased discharge Flow rate, effect of increasing piston displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

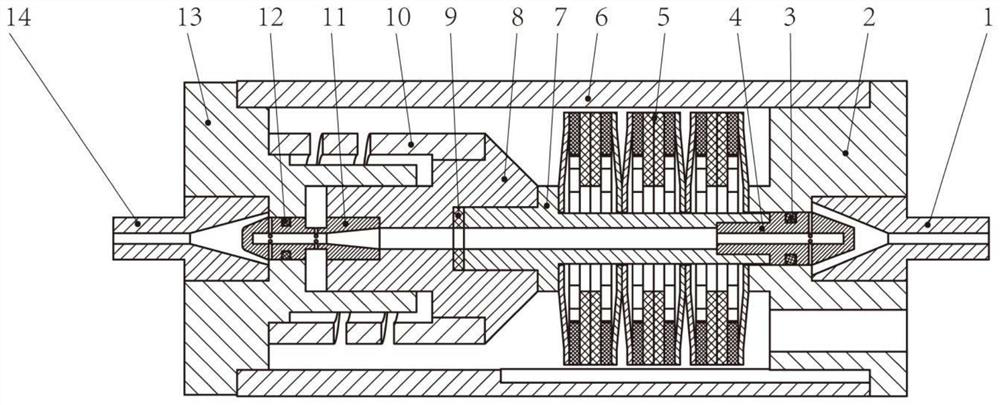

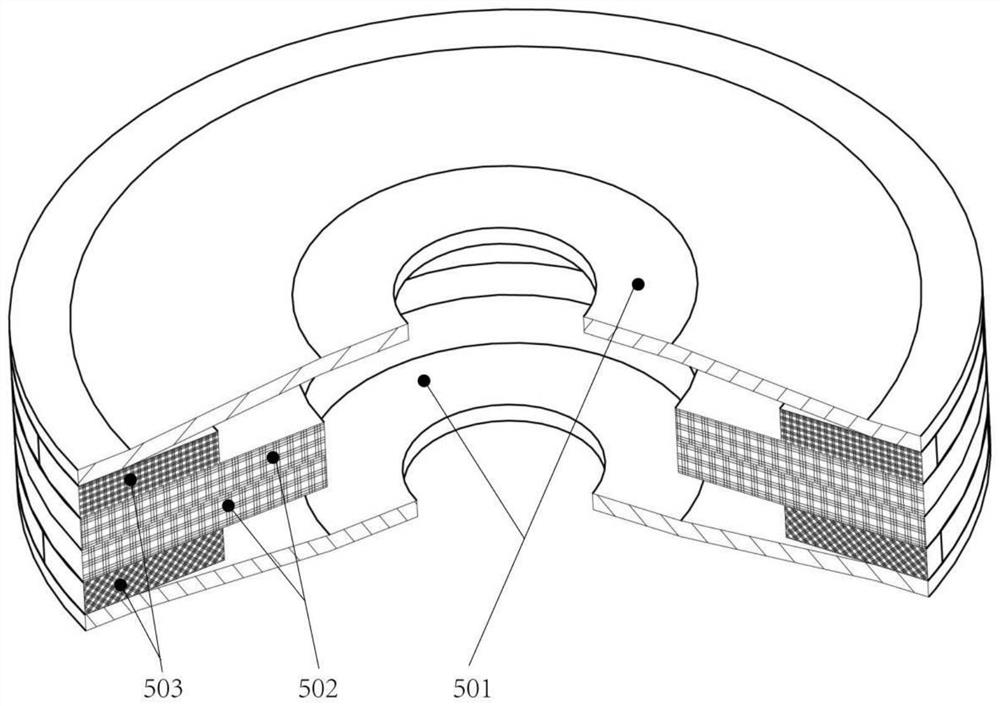

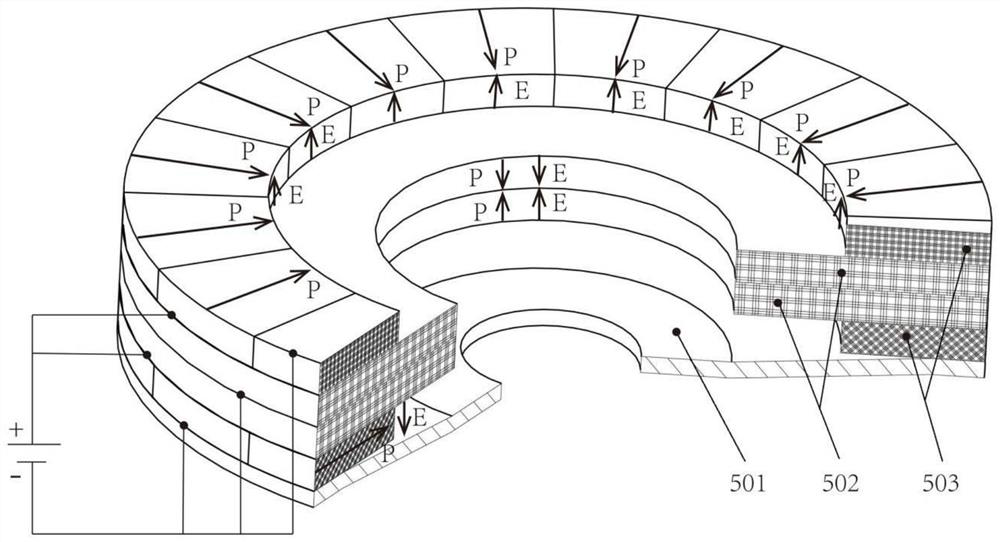

[0025] Such as Figure 1-6 As shown, this embodiment provides a resonant piezoelectric stack pump with a slide valve, the main structure includes a water inlet 1, a first end cover (right end cover) 2, a sealing ring 3, an inlet slide valve 4, and a cymbal-shaped pressure pump. Electric stack 5, shell 6, intermediate connecting pipe 7, piston 8, sealing gasket 9, cylinder with spiral groove 10, outlet slide valve 11, sealing ring 12, second end cover (left end cover) 13, water outlet 14 .

[0026] Wherein, in this embodiment, the water inlet 1 and the right end cover 2 are integrally connected by threads, and may also be connected by a quick plug-in interface in practical applications. The right end cover 2 and the housing 6 are connected by threads. The right end cover 2 is provided with an offset round through hole, and the right end of the housing 6 is provided with a groove for arranging the power line of the cymbal-shaped piezoelectric stack 5 . The left end cover 14 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com