Electric locomotive motor system

A technology for electric locomotives and motor bodies, applied in the field of electric motors, can solve the problems of manual adjustment of output power and poor passability, and achieve good energy utilization efficiency, output torque enhancement, and high energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

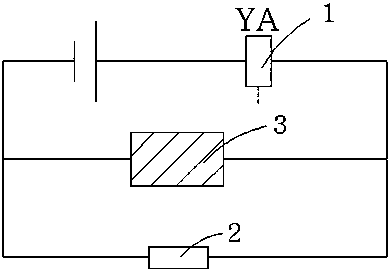

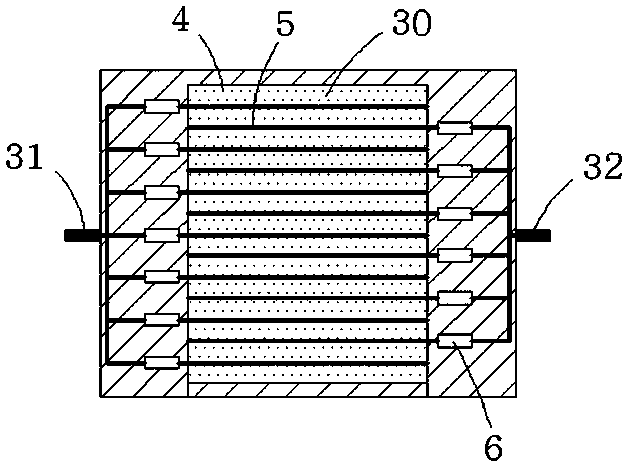

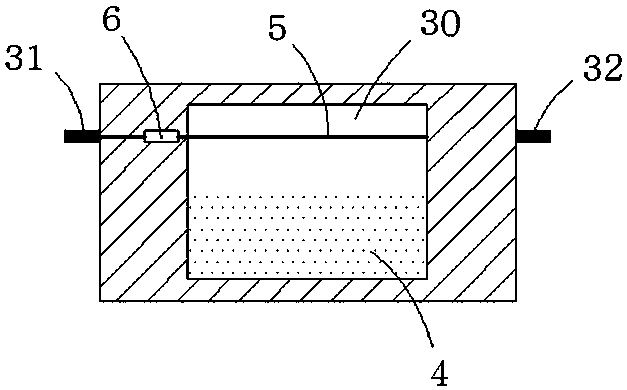

[0014] Such as Figure 1 to Figure 3 In the first embodiment shown, the electric locomotive motor system includes a motor body, which has an excitation device 1 that provides a working magnetic field, and the excitation device 1 is electrically connected to the power supply through a fixed value resistor 2; and in the fixed value A dynamic resistor 3 is connected in parallel on the value resistance 2; the dynamic resistor 3 includes a closed cavity 30, and mercury 4 is sealed in the cavity 30, and mercury 4 is equidistantly distributed at intervals of 1 mm to 2 mm above the liquid surface Conductive metal rods 5 parallel to each other and extending longitudinally along the entire inner cavity 30, and one of the two adjacent conductive metal rods 5 is electrically connected to the dynamic resistor after a protective resistor 6 is connected in series The first electrode 31 of the dynamic resistor 3 is electrically connected to the second electrode 32 of the dynamic resistor 3 af...

Embodiment 2

[0018] Such as Figure 4 The difference between the shown embodiment two and the first embodiment is that the inner bottom surface of the inner cavity 30 is made into a wave surface that undulates along the running direction of the electric locomotive; In the process of acceleration and deceleration with higher requirements, even under the flat terrain, the mercury 4 can form large undulations and contaminate the conductive metal rod 5 under the oblique thrust of the wave surface, so that Temporarily increase the output power of the motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com