An electromagnetic speed controller

An electromagnetic speed regulation and magnetic pole technology, applied in asynchronous induction motors, electrical components, electromechanical devices, etc., can solve the problems of complex mechanical device structure, small size of permanent magnets, limited speed regulation range, etc., to improve reliability and low cost. , the effect of reducing the current impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

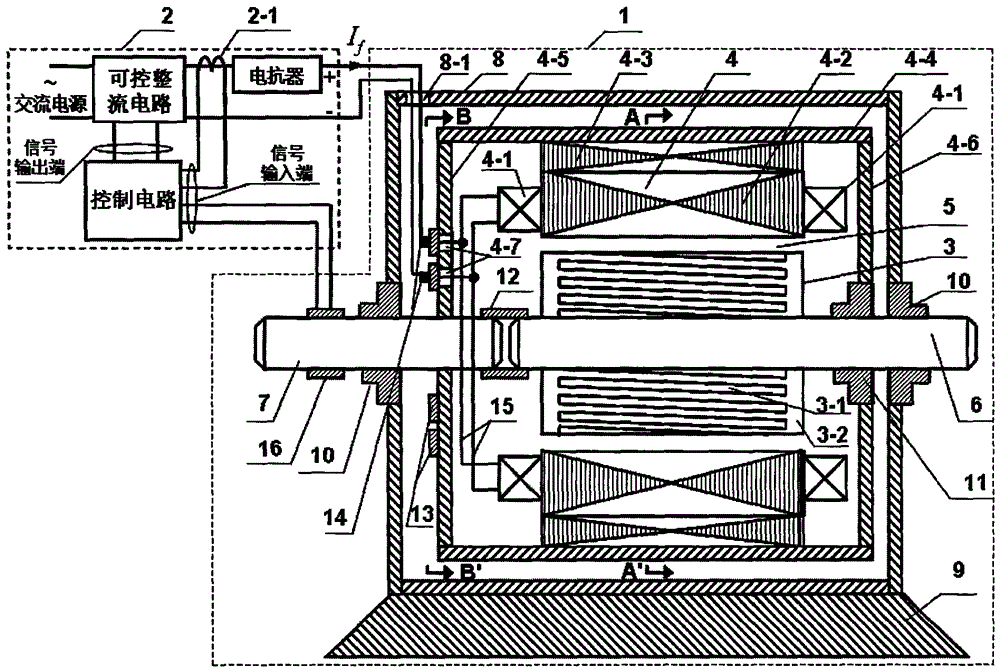

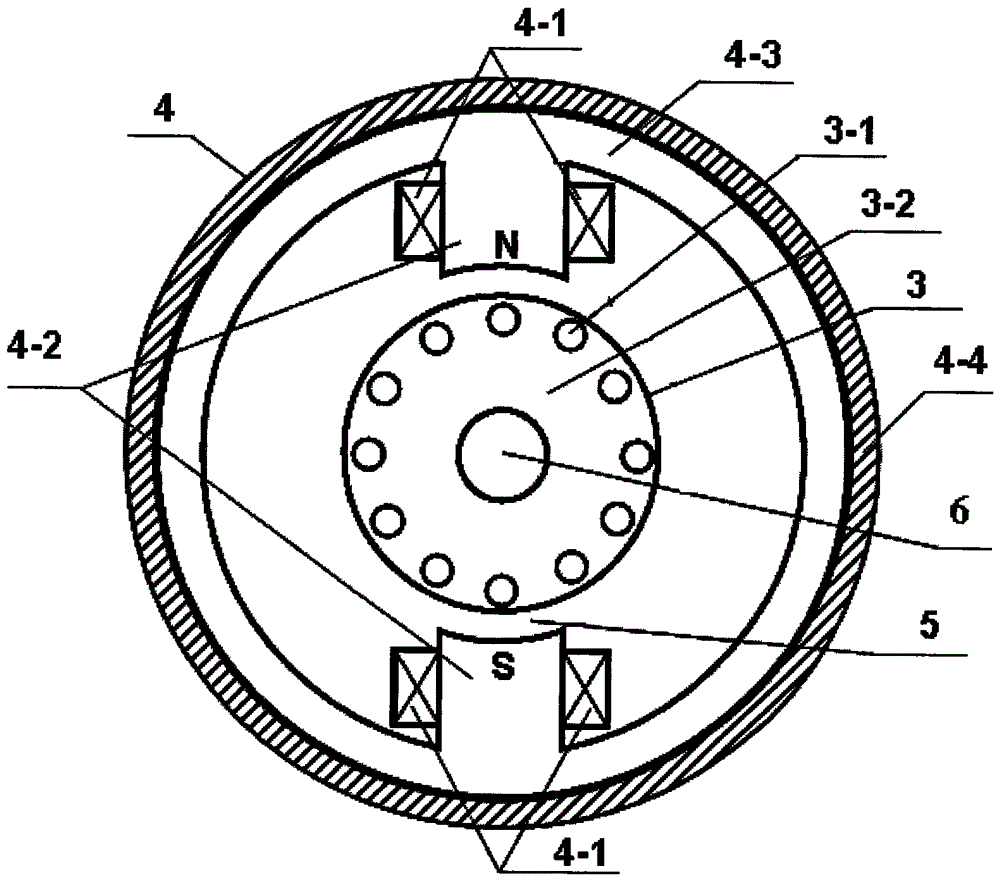

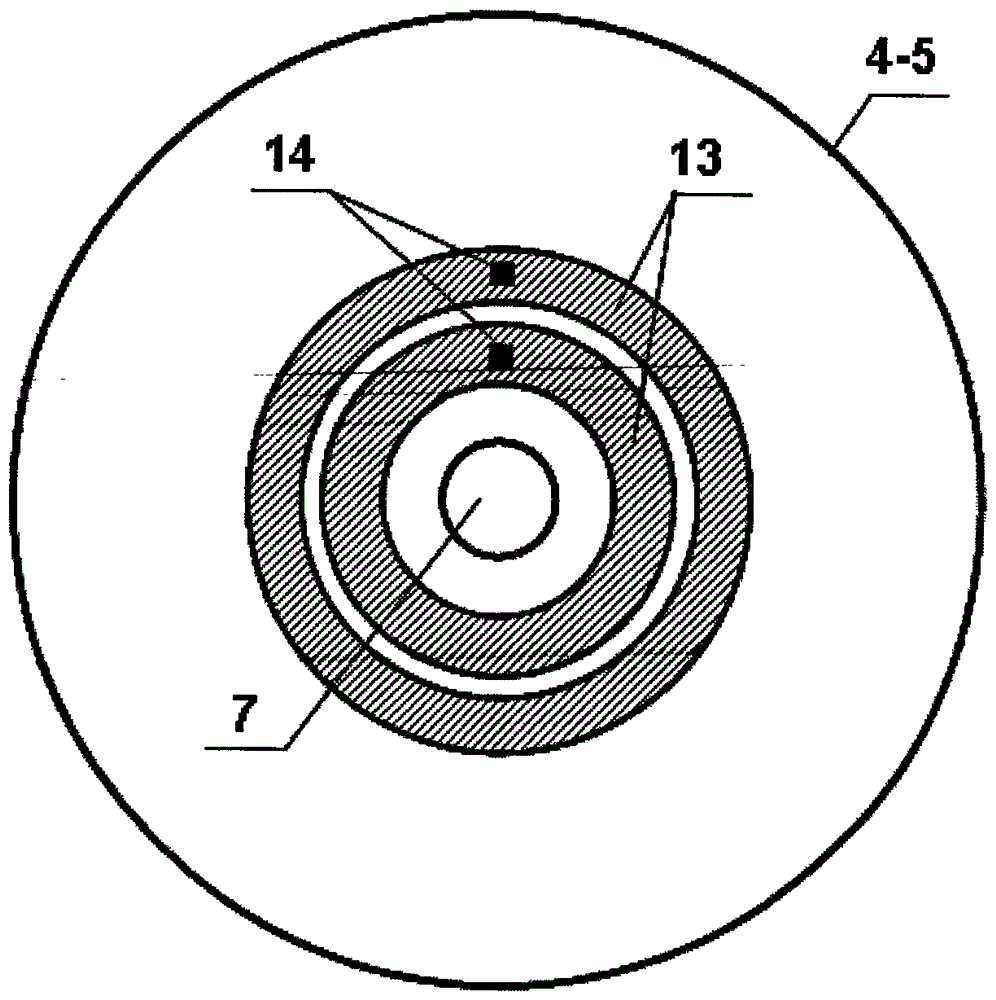

[0033] Refer to attached figure 1 , 2 , an electromagnetic speed regulating machine, composed of an electromagnetic speed regulating machine body 1 and a DC excitation circuit 2. Electromagnetic governor body 1 consists of inner rotor 3, outer rotor 4, inner rotor shaft 6, outer rotor shaft 7, casing 8, frame 9, bearing 10, outer rotor bearing 11, combined bearing 12, conductive slip ring 13, Brush 14, wire 15, speed sensor 16 constitute; DC excitation circuit 2 is constituted by controllable rectification circuit, current sensor 2-1, reactor, control circuit and connecting wire.

[0034]The inner rotor 3 includes a squirrel-cage winding 3-1 and an iron core 3-2, which is the same as the rotor of a traditional squirrel-cage AC asynchronous motor; the inner rotor 3 is sleeved on the inner rotor shaft 6; the inner rotor shaft 6 It is installed on the casing 8 and the outer rotor end cover 4-6 through two bearings 10, 11; the casing 8 is fixed on the frame 9.

[0035] The oute...

Embodiment 2

[0040] Refer to attached Image 6 , another embodiment of an electromagnetic speed regulating machine. The two iron core poles 4-2 of the outer rotor 4 in the first embodiment are increased to four, and by connecting the concentrated winding 4-1 on the iron core poles with the positive and negative output terminals of the DC excitation circuit 2, two adjacent The polarities of the core poles 4-2 are reversed. By analogy, the number of core poles can be increased to six, eight, ten, twelve, etc.

Embodiment 3

[0042] Refer to attached Figure 7 , another embodiment of an electromagnetic speed regulating machine. In Embodiment 1, the outer rotor cover 4-6 and the connected bearing 10 are removed, so that the outer rotor 4 becomes a cup-shaped structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com