Up-mounting type plastic ball-valve

A technology for plastic ball valves and top loading, applied in the field of plastic ball valves, which can solve problems such as manufacturing and assembly difficulties, affecting pre-tightening force, small pre-tightening force of sealing surface, etc., and achieves the effect of avoiding welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

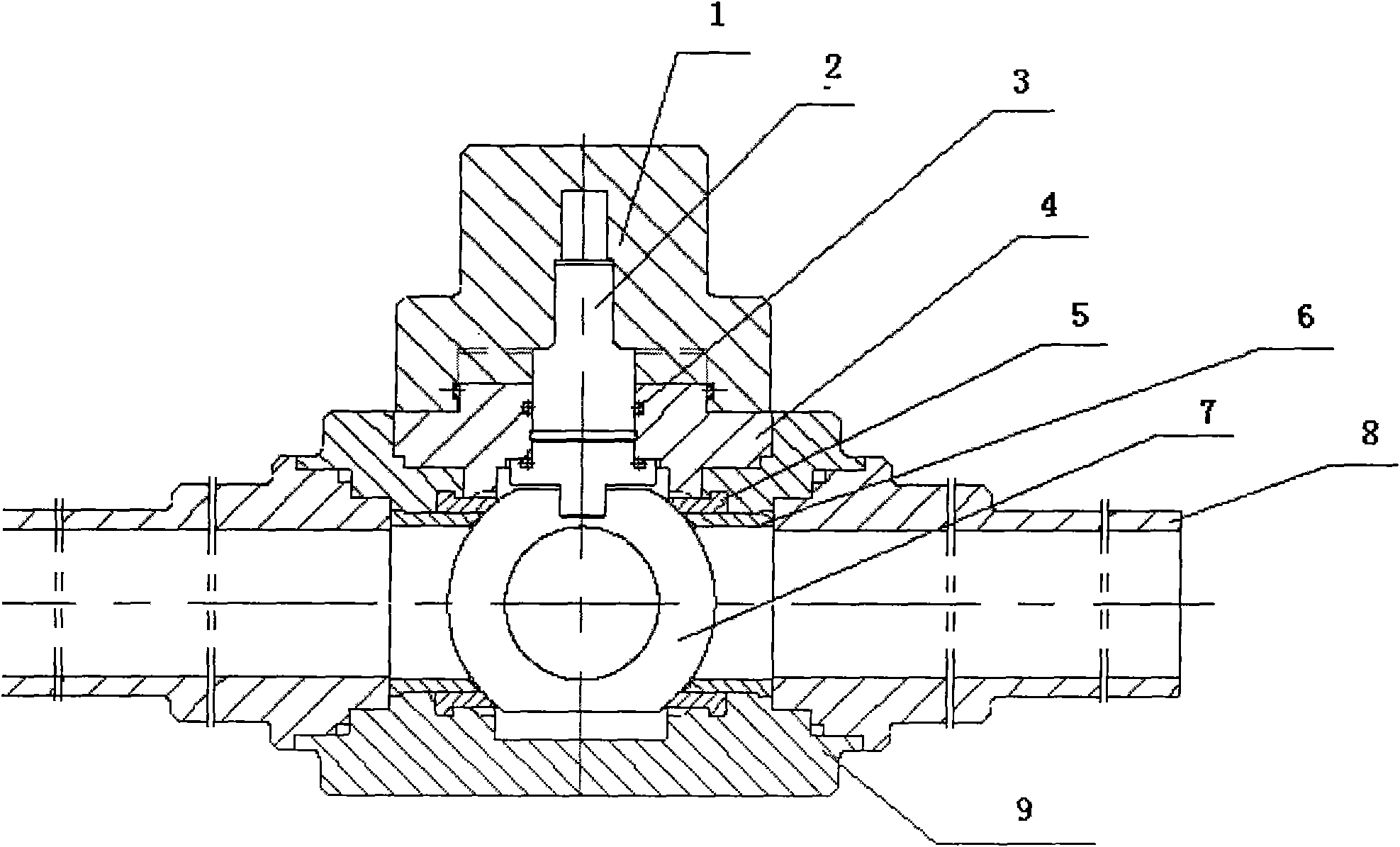

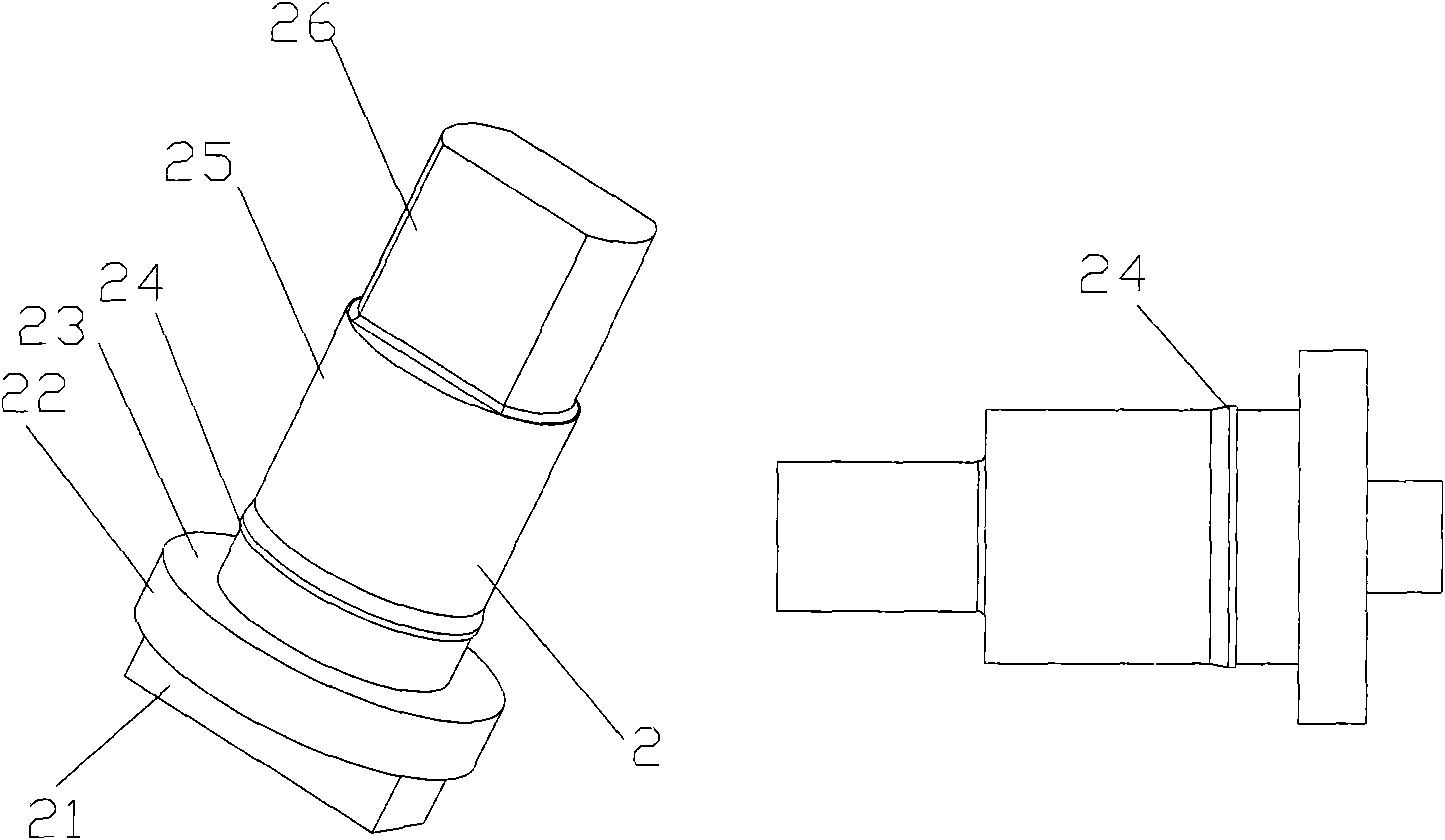

[0032] Refer to attached figure 1 The overall structure diagram of the PE ball valve shown. The plastic ball valve of the present invention is composed of a valve stem cap 1, a valve stem 2, a valve stem sealing ring 3, a valve cover 4, a valve ball sealing ring 5, a valve ball sealing ring support ring 6, a valve ball 7, a connecting pipe 8, and a valve body 9 .

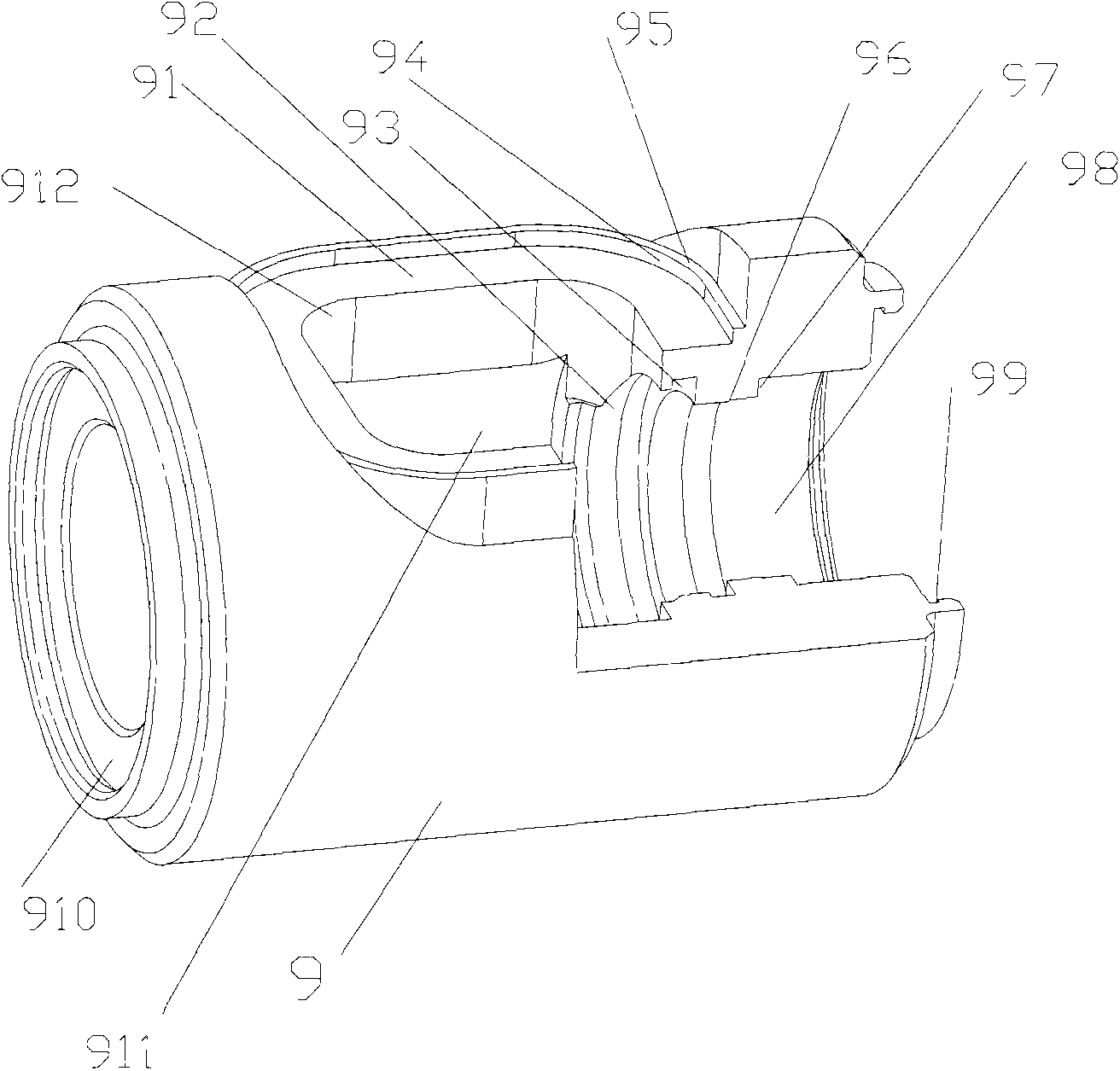

[0033] Refer to attached figure 2The structure diagram of the PE ball valve body shown. The valve body 9 is generally a cylinder with a series of cylindrical holes in it. These cylindrical holes communicate with each other, and their axes coincide with the axis of the cylinder of the valve body. The valve body 9 includes a bonnet melt surface 91, a bonnet annular positioning surface 94, a bonnet axial locating surface 95, an inner cylindrical surface 92 matched with the valve ball sealing ring 5, a valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com