Fastener pre-tightening force control device

A control device and pre-tightening force technology, which is applied in the direction of threaded fasteners, locking fasteners, connecting components, etc., can solve the problems of inability to obtain the tightening force of fasteners and easy loosening of fasteners, and achieve improved fixing quality, simplify the installation process, and avoid misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

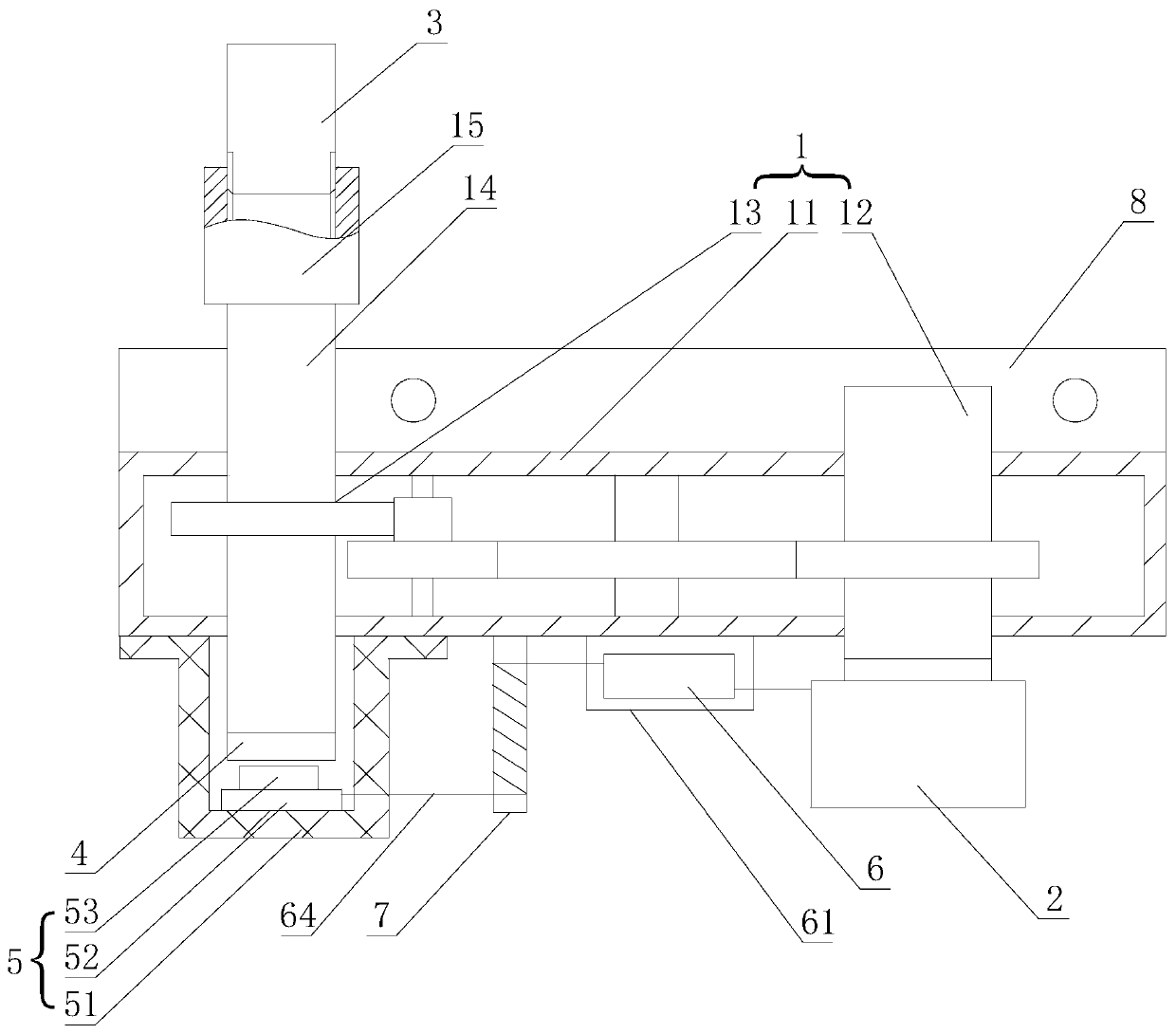

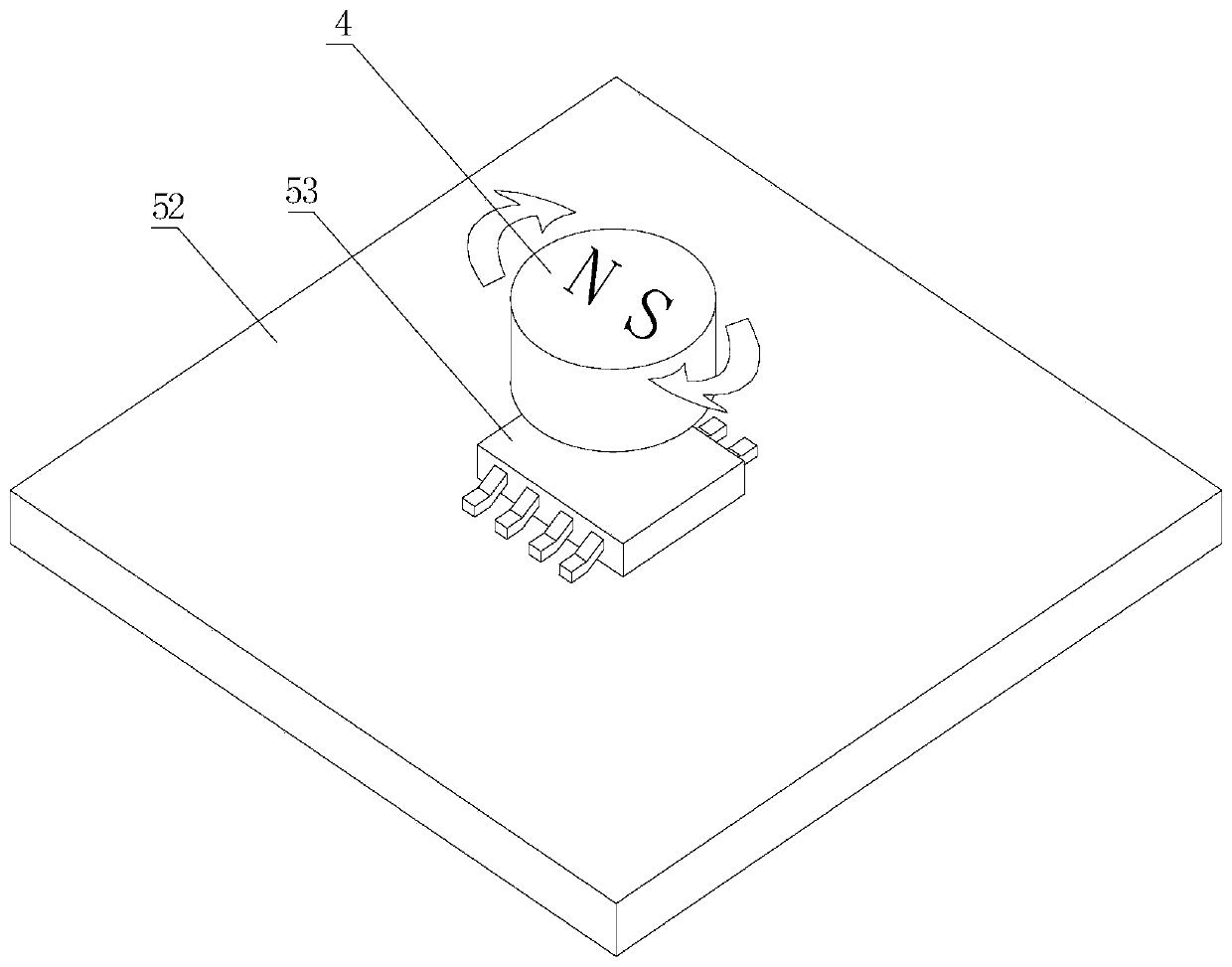

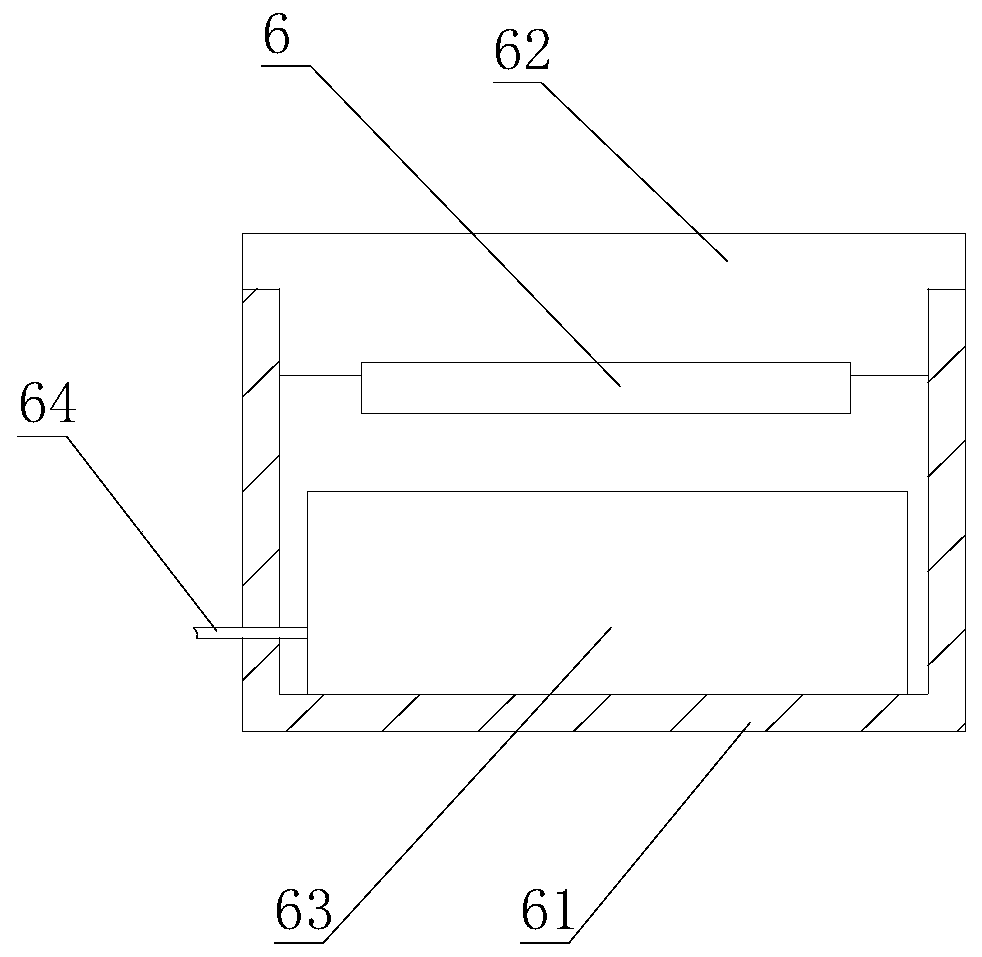

[0026] Such as figure 1 , figure 2 , image 3 As shown, a fastener pre-tightening force control device includes a gear reducer 1. The gear reducer 1 includes a housing 11, an input end 12 and an output end 13, between the input end 12 and the output end 13 A gear transmission mechanism is provided. The input end 12 is connected with a power unit 2. The power unit 2 can select a suitable power unit according to actual operation, such as a motor or a wrench. The output end 13 includes a pre-tightening force The connector 3, and the magnetic column 4 for identifying the rotation angle of the output end 13, the magnetic column 4 includes an N pole and an S pole, and the N pole is arranged at one end of the magnetic column 4, and the S pole is arranged on the other side of the magnetic column 4. At one end, the box 11 is also provided with a sensor 5 for detecting the rotation angle of the magnetic column 4, and a control chip 6 is connected to the sensor 5, and the control chip 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com