Auxiliary clamping device for disc-hydraulic-type turbine disc tool

A technology for auxiliary clamping and turbine disk, applied in positioning devices, clamping, manufacturing tools, etc., which can solve the problems of poor stability, weak stability, and thin turbine disk tooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention will be further described:

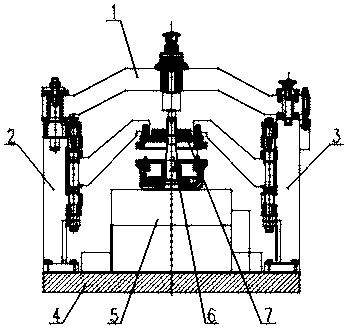

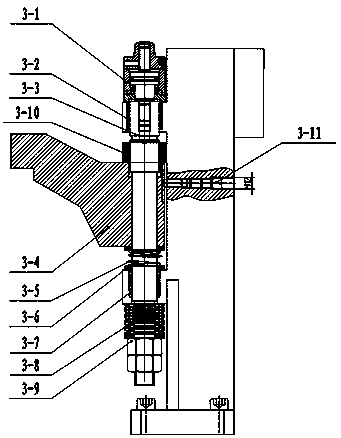

[0019] like figure 1 and figure 2 As shown, this embodiment includes clamp body base 4, crossbeam 1, left column 2, right column 3 and two groups of presser foot adjustment components consisting of oil cylinder 3-1, upper bushing 3-2, pull rod 3-3, adjustment lock nut 3-10, presser foot 3-4, spring 3-5, gasket 3-6, lower bushing 3-7, nut 3-9, disc spring 3-8, positioning device 3-11,

[0020] The lower ends of the left column 2 and the right column 3 are symmetrically arranged on the clamp body base 4 through bolt connection, and an indexing plate 5 is installed at the center position on the upper side of the clamping body base 4, and the tooling 6 is installed on the upper side of the indexing plate 5, and the left column 2 1. The top of the right column 3 is fixedly connected with the left and right ends of the crossbeam 1 through taper sleeves and bolts; the middle p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com