Torque sensor capable of measuring six-dimensional non-coplanar force

A technology of torque sensor and six-dimensional space, which is applied in the direction of measuring device, measurement of property and force of applied piezoelectric resistance material, instrument, etc., can solve the problems of complex post-processing circuit, complex processing technology, high processing requirements, etc., and achieve improved resistance Effects of interference capability, high measurement accuracy, low machining and assembly requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings.

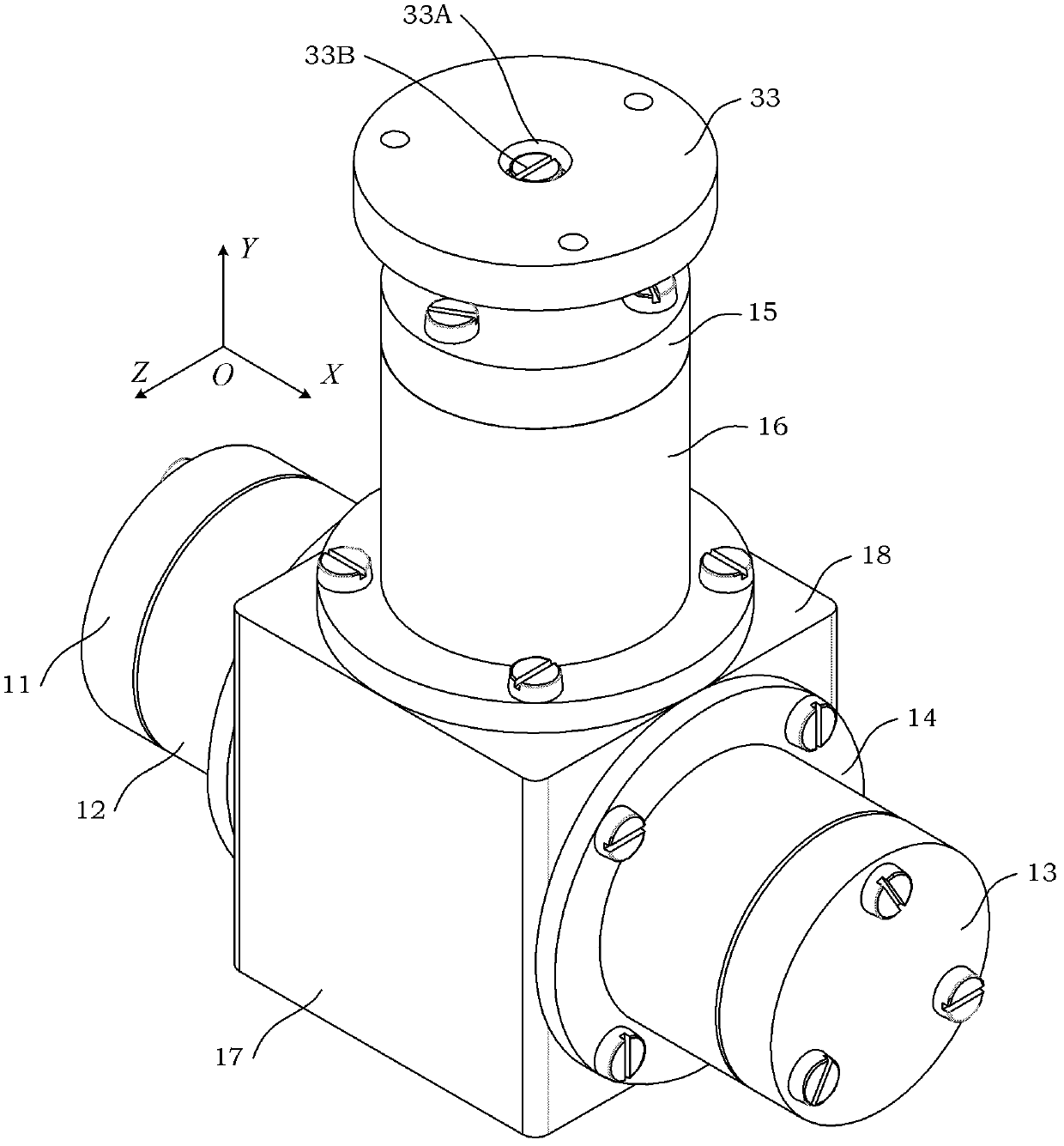

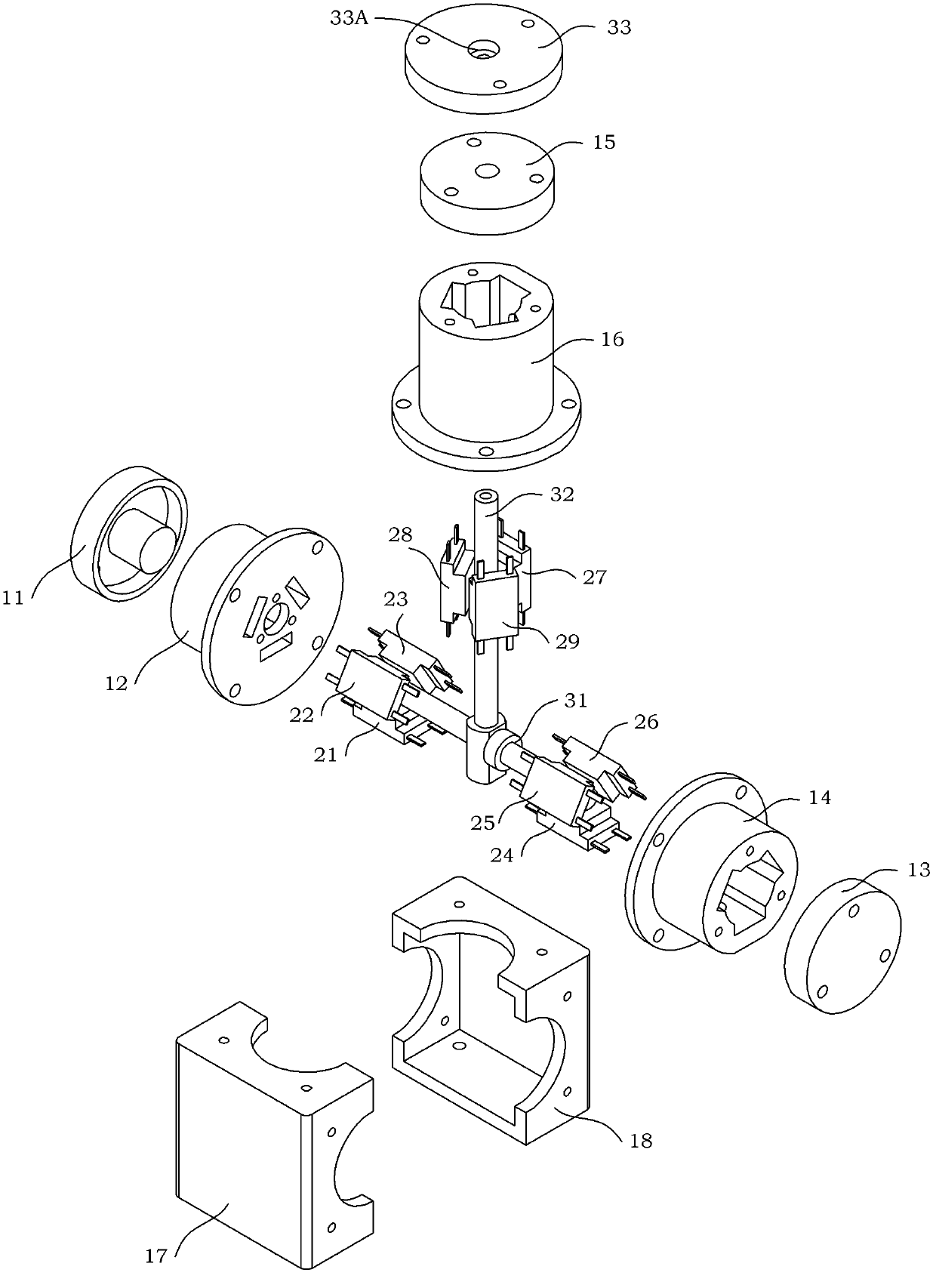

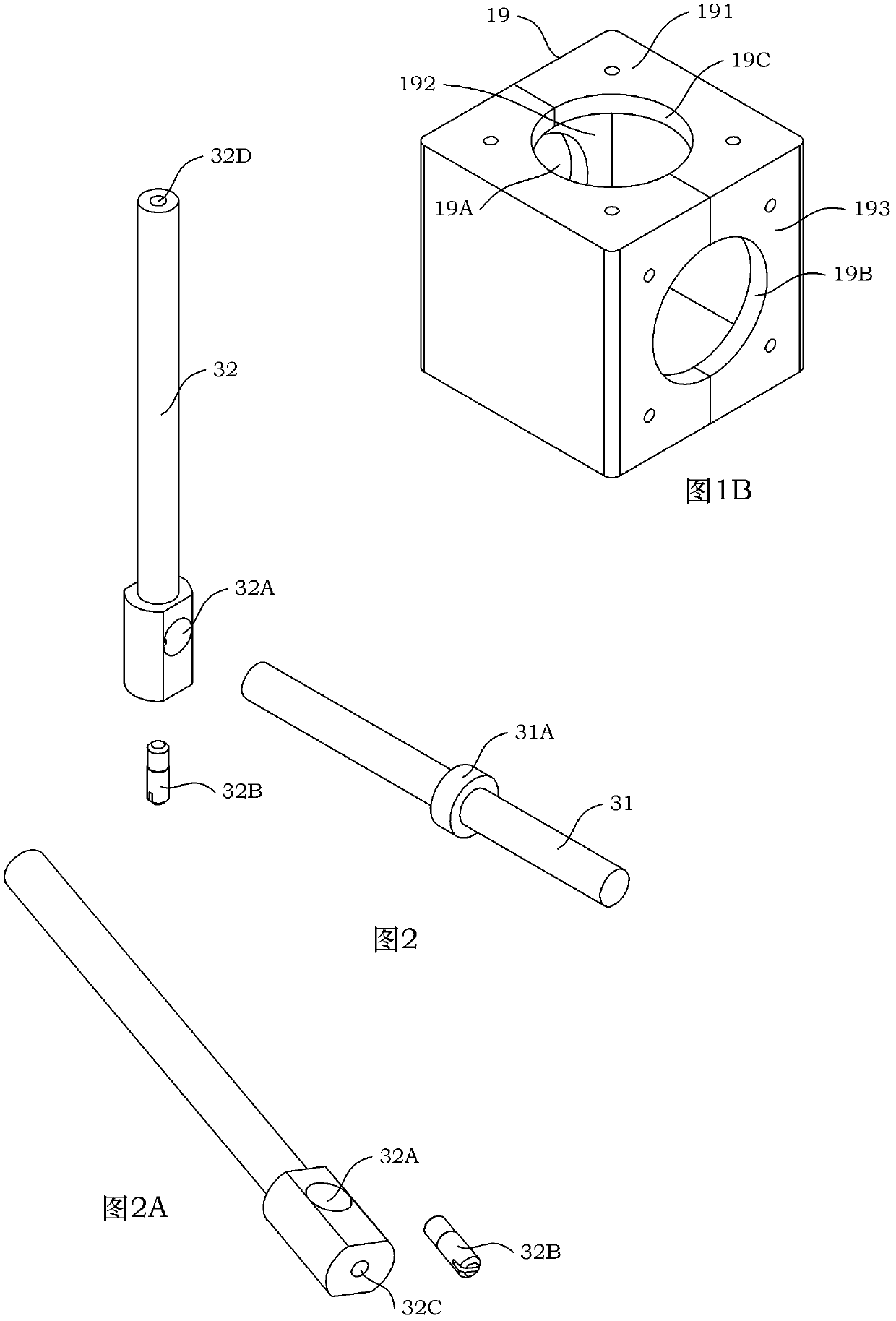

[0045] see figure 1 , Figure 1A Shown, a kind of moment sensor of the present invention that can realize six-dimensional space force measurement, this moment sensor includes nine sensors (the first sensor 21, the second sensor 22, the third sensor 23, the fourth sensor 24, the fifth sensor Sensor 25, the sixth sensor 26, the seventh sensor 27, the eighth sensor 28, the ninth sensor 29), three end caps (first end cap 11, second end cap 13, third end cap 15), three Mounting bases (first mounting base 12 , second mounting base 14 , third mounting base 16 ), an X-axis connecting rod 31 , a Y-axis connecting rod 32 , a loading flange 33 and a support frame 19 . Wherein, the X-axis connecting rod 31 and the Y-axis connecting rod 32 are assembled to form a T-shaped connecting rod.

[0046] In the present invention, the nine sensors are selected from the FSS 1500...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com