Overcurrent electromagnetic release

An electromagnetic release and overcurrent technology, which is applied in the direction of circuits, electrical components, and parts of protective switches, can solve the problems of large volume of releases, expand the application range, reduce operating time, and improve operating efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

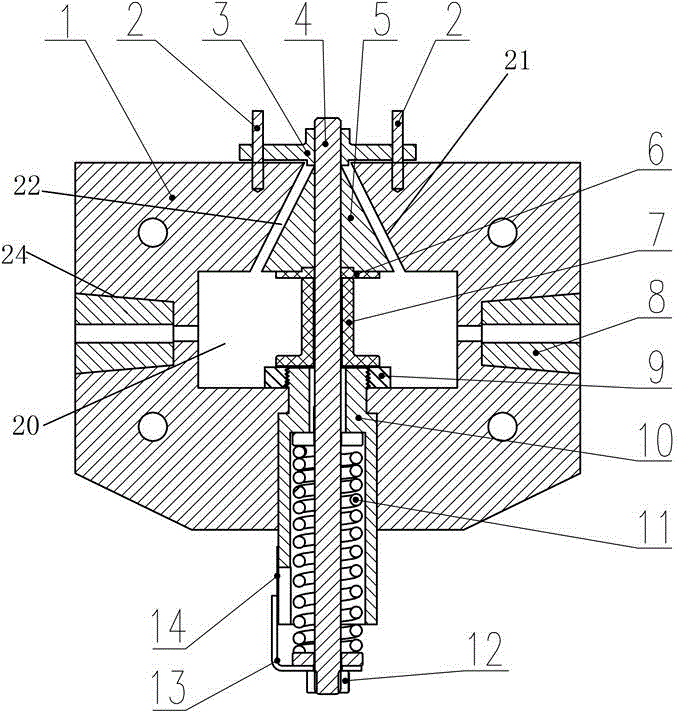

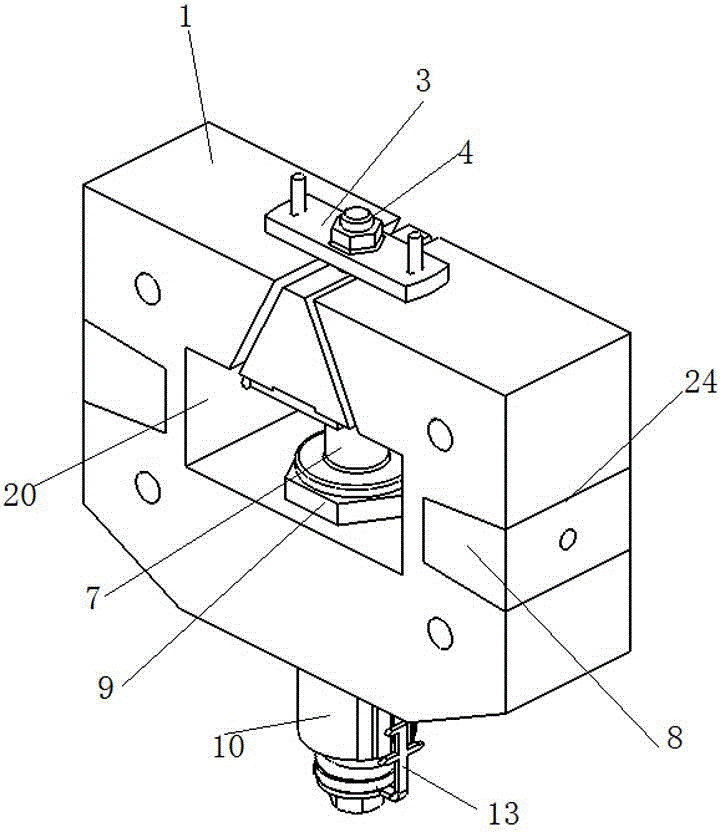

[0026] Such as figure 1 , figure 2 As shown, an embodiment of an overcurrent electromagnetic release, the release in this embodiment includes an annular yoke frame 1, the yoke frame 1 has a circumferential ring wall and a wall surrounded by the circumferential ring wall extending along the front and rear direction The central hole 20 for the system line to pass through, and an upper notch 21 is provided on the inner wall surface of the top ring wall of the yoke frame, and the upper notch 21 extends from the inner wall surface of the top ring wall of the yoke frame 1 to the yoke On the outer wall surface of the ring wall at the top of the iron frame 1, an armature 5 is reciprocatingly moved up and down in the upper gap 21, and the armature 5 moves upward to control tripping and opening when the system line is overcurrent or short-circuited. , the armature 5 is a triangle with a small upper part and a larger lower part, and the upper notch 21 is an angular notch with a smaller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com