Electromagnetic coil groove of automobile air-conditioning clutch

A technology for electromagnetic coils and automotive air conditioners, applied in clutches, magnetic drive clutches, non-mechanical drive clutches, etc., can solve the problems of high energy consumption, low production efficiency, and large processing allowance, and achieve cost reduction, resource conservation, and The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

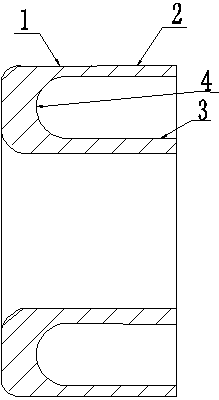

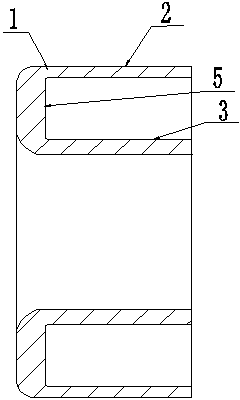

[0012] The present invention as figure 2 shown.

[0013] The electromagnetic coil groove of the automobile air conditioner clutch includes the electromagnetic coil groove 1, the inner wall 3, the outer wall 2 of the electromagnetic coil groove 1 and the plane 4 at the bottom of the electromagnetic coil groove are all formed by one-time cold extrusion.

[0014] Wherein the bottom of the electromagnetic coil slot is a plane.

[0015] In order to ensure the quality of the cold extrusion process, the key control of each process:

[0016] 1. Forging pre-forming should leave a suitable margin for cold pressing, mainly the ring groove (coil) margin, to prepare for the subsequent precision forming;

[0017] 2. The heat treatment (annealing) process adjusts the structure and hardness of the forged billet, and ensuring a good internal structure and appropriate hardness is the key preparation for the cold extrusion process;

[0018] 3. The phosphorus saponification process is the mos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com