Electromagnetic power-supply general switch

An electromagnetic, main switch technology, applied in electrical switches, circuits, electrical components, etc., can solve the problems of poor sealing at the bottom of the switch shell, poor anti-interference ability, and the switch cannot work normally, so as to reduce the working current of the coil. , reliable performance, the effect of avoiding quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

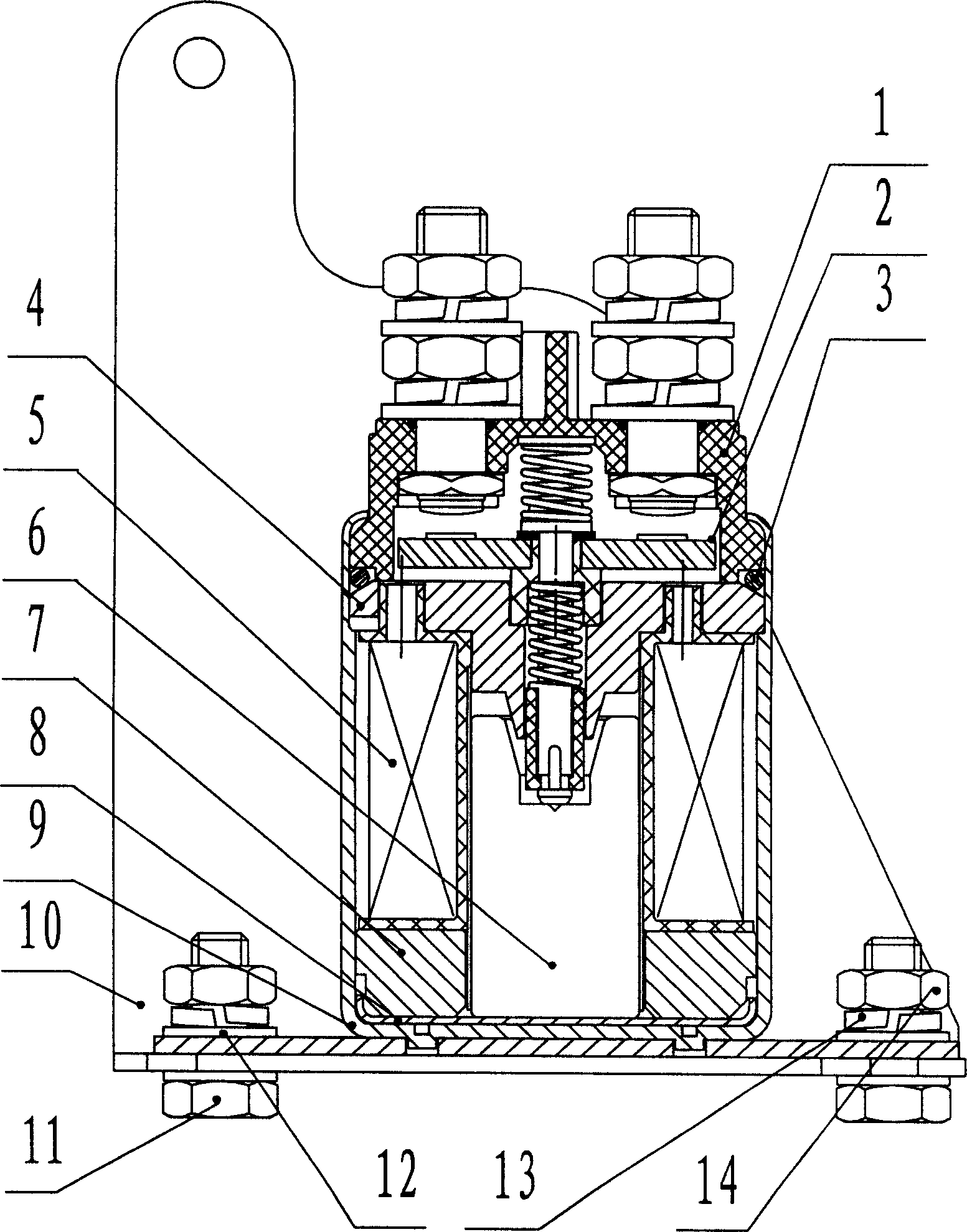

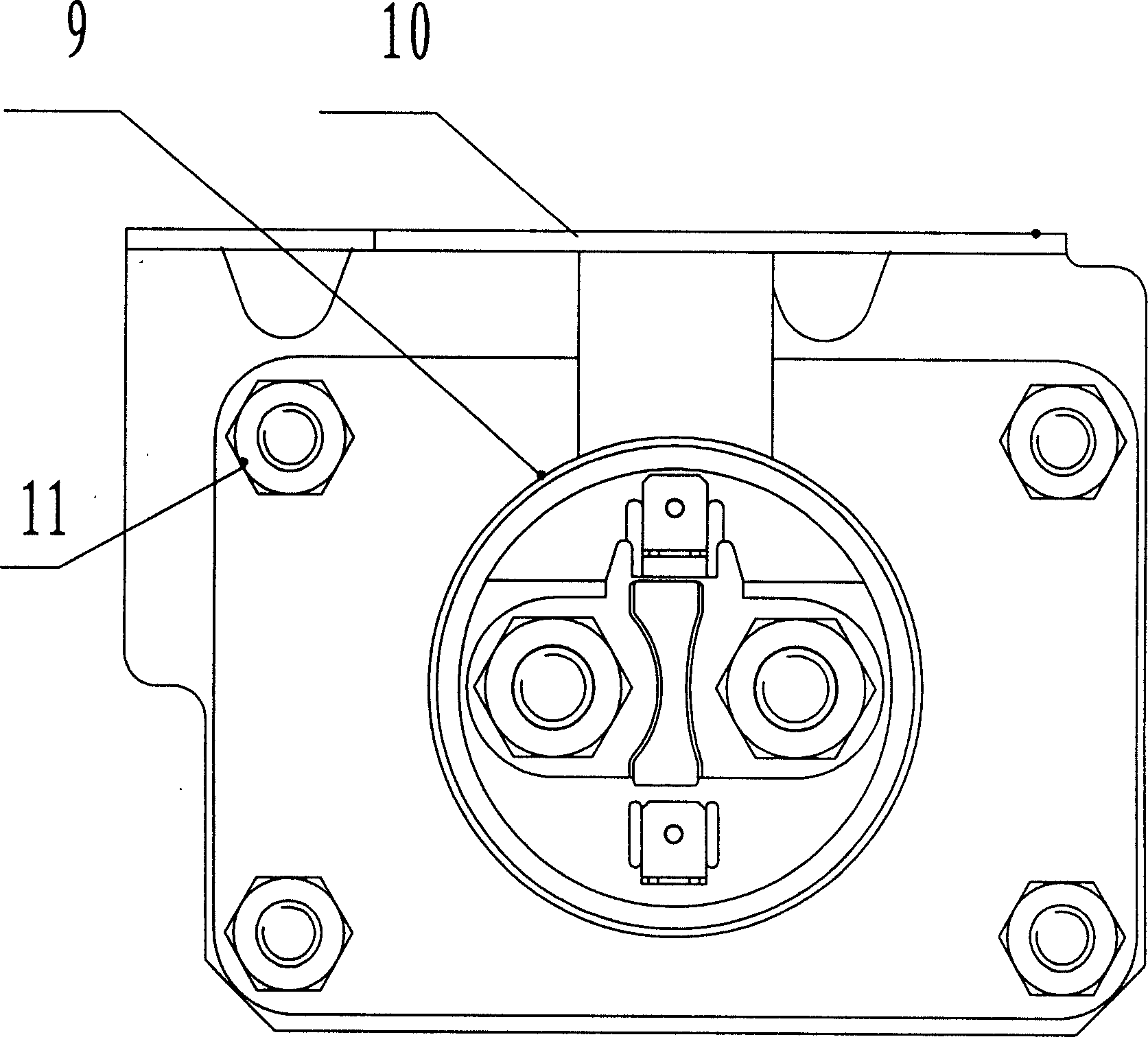

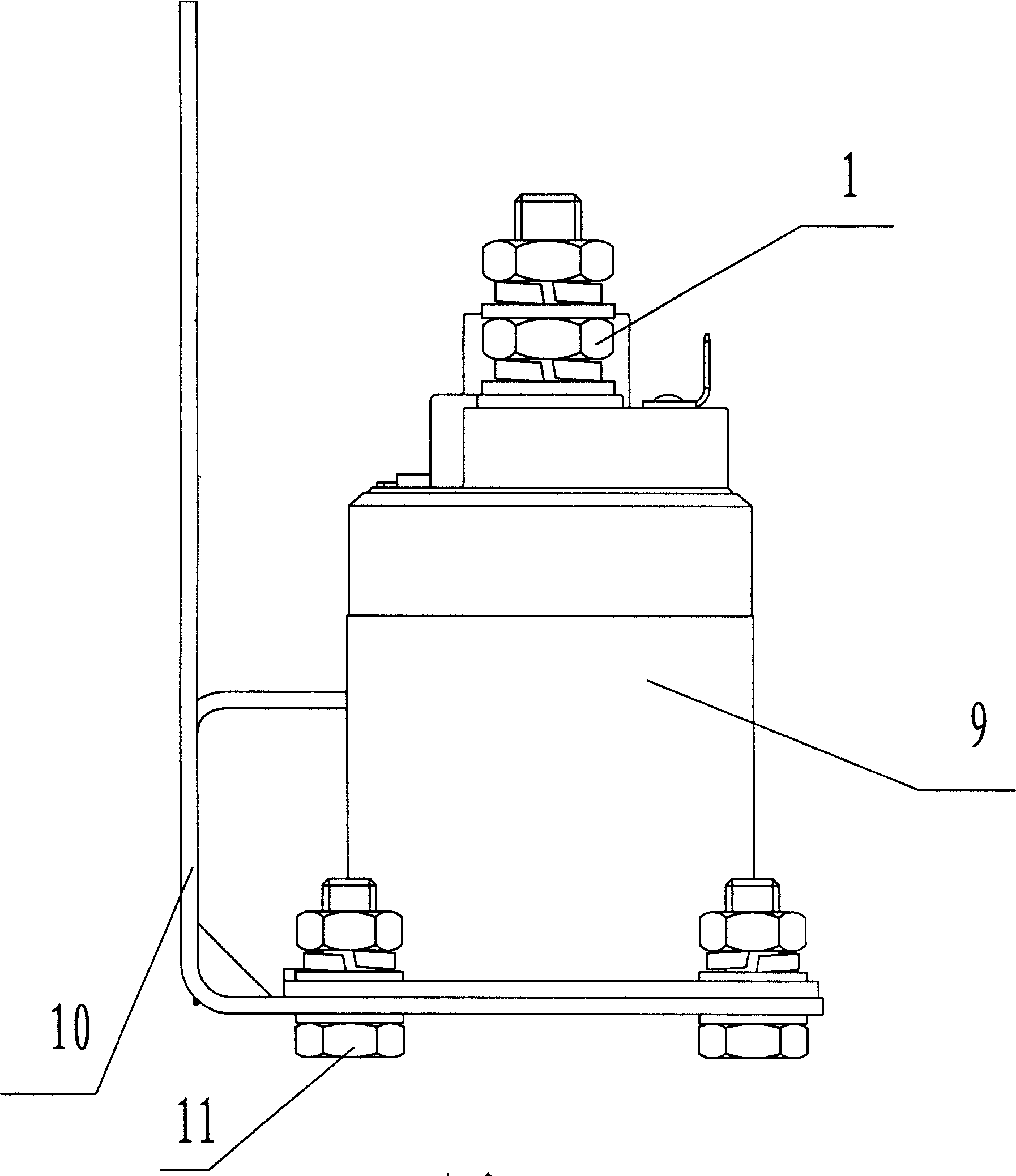

[0021] see figure 1 As shown, this electromagnetic power master switch includes a shell assembly 9, and the shell assembly 9 is fixed on the bracket 10, and the mounting hole on the bracket 10 is 2-Φ7mm. The shell assembly 9 is provided with a base assembly 1, a contact assembly 2, a flange 4, a coil assembly 5, an iron core 6, and a backing plate 7, wherein the flange 4 is arranged on the top of the coil assembly 5, and the contact assembly 2 is set on the flange 4, the base assembly 1 is covered above the contact assembly 2, and its bottom peripheral edge is in contact with the flange 4, and a sealing ring 3 (51.5×2.65) is provided at the junction, The iron core 6 is installed in the copper pipe 5-4 of the coil assembly 5, and the bottom of the coil assembly 5 is provided with a backing plate 7 covering the copper pipe 5-4, and the iron core 6, the backin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com