Pilot valve assembly

A pilot valve and component technology, applied in the field of solenoid valves, can solve the problems of static iron core absorption, high cost, difficult to return, etc., to achieve the effect of smaller wire diameter, lower cost, and avoid complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

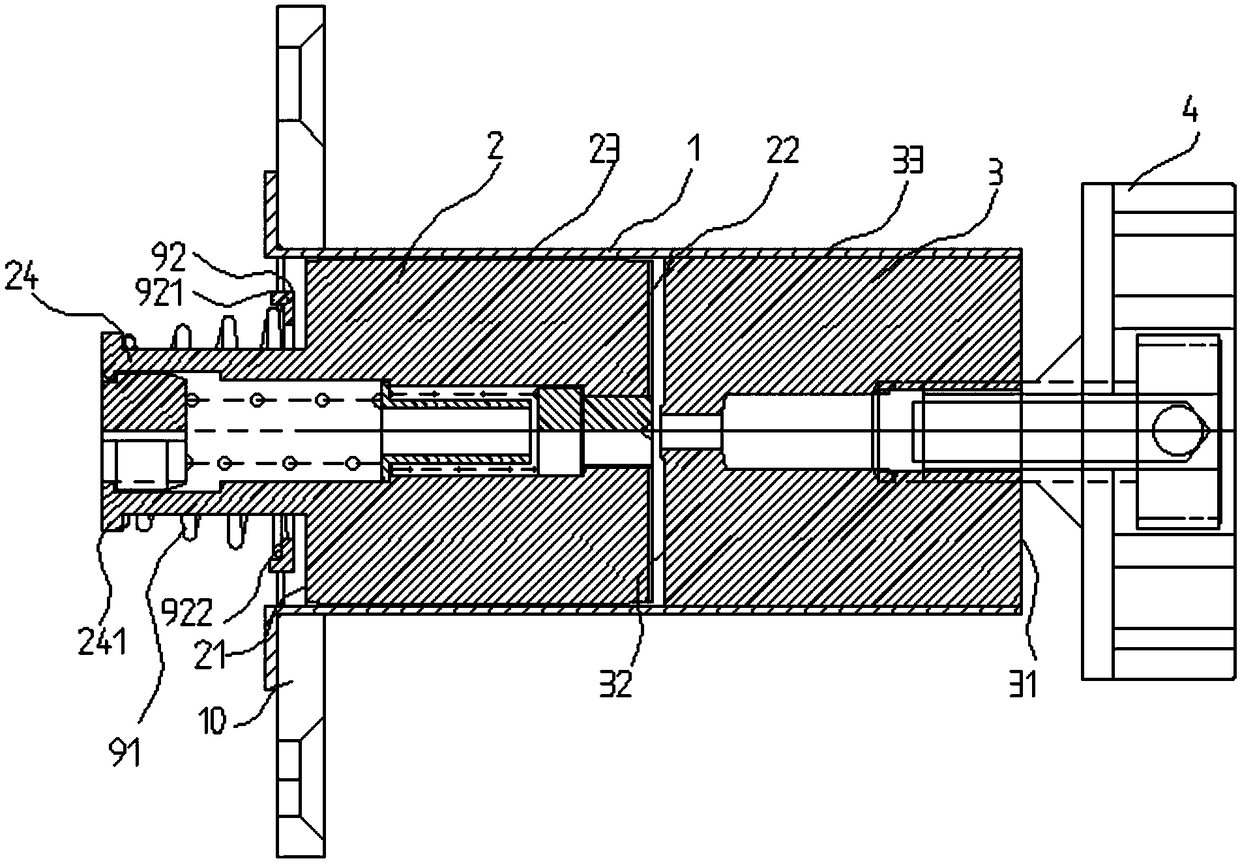

[0046] In this embodiment, the pilot valve assembly includes a sleeve structure 1 , a first moving iron core 2 , an elastic device (not shown), a static iron core 3 and a fixing device 4 . The above-mentioned components are mainly introduced below.

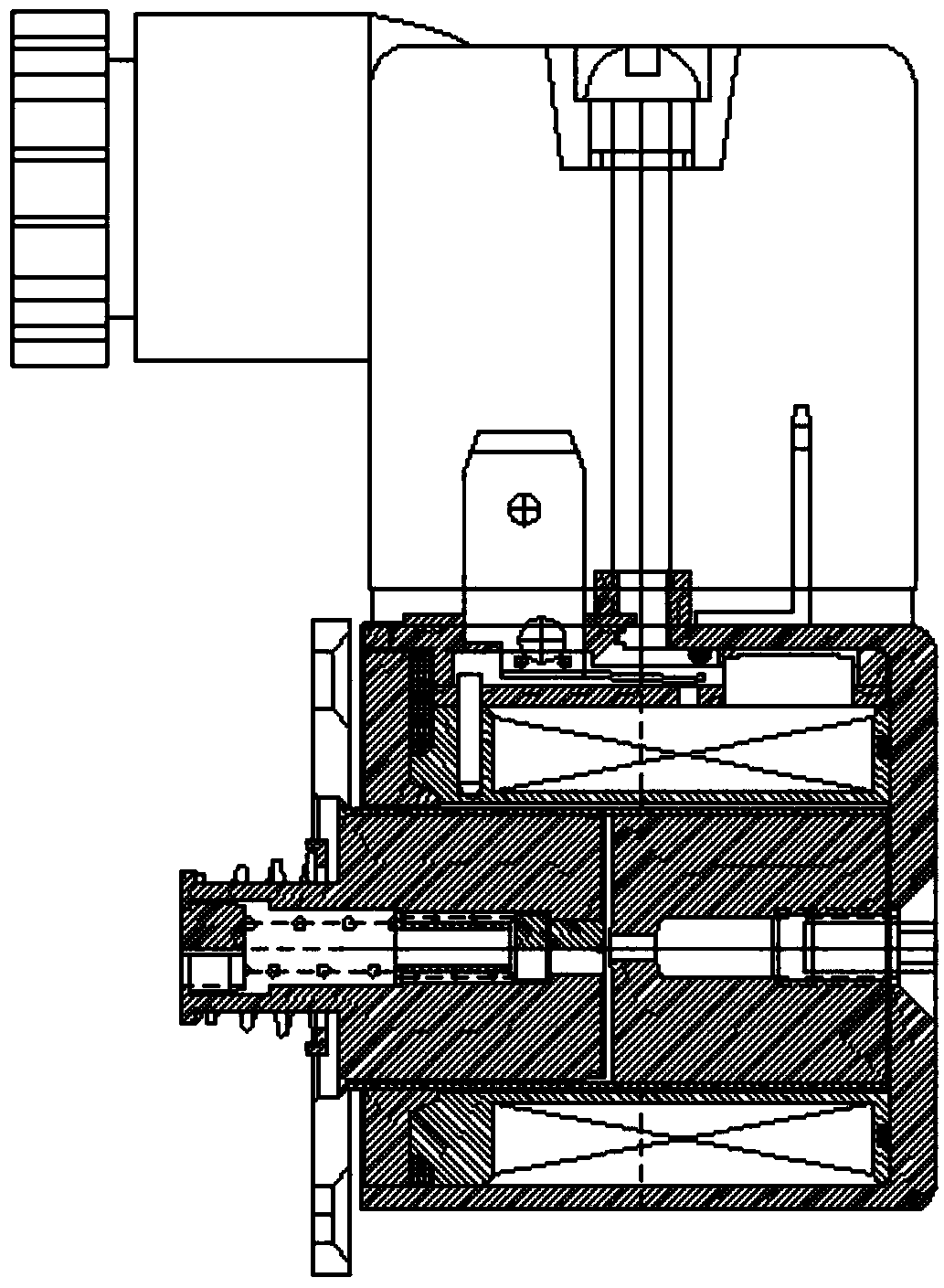

[0047] For details, please refer to Figure 1 to Figure 2 , Figure 12 to Figure 13 , figure 1 It is a schematic cross-sectional structure diagram of a pilot valve assembly in Embodiment 1 of the present invention; figure 2 It is a schematic cross-sectional structure diagram of a solenoid valve composed of a pilot valve assembly in Embodiment 1 of the present invention; Figure 12 It is a schematic diagram of a horizontal cross-sectional structure of the first structure of the sleeve structure of a pilot valve assembly in the present invention; Figure 13 It is a schematic cross-sectional structural schematic diagram of a vertical section of the first structure of a sleeve structure of a pilot valve assembly in the present in...

Embodiment 2

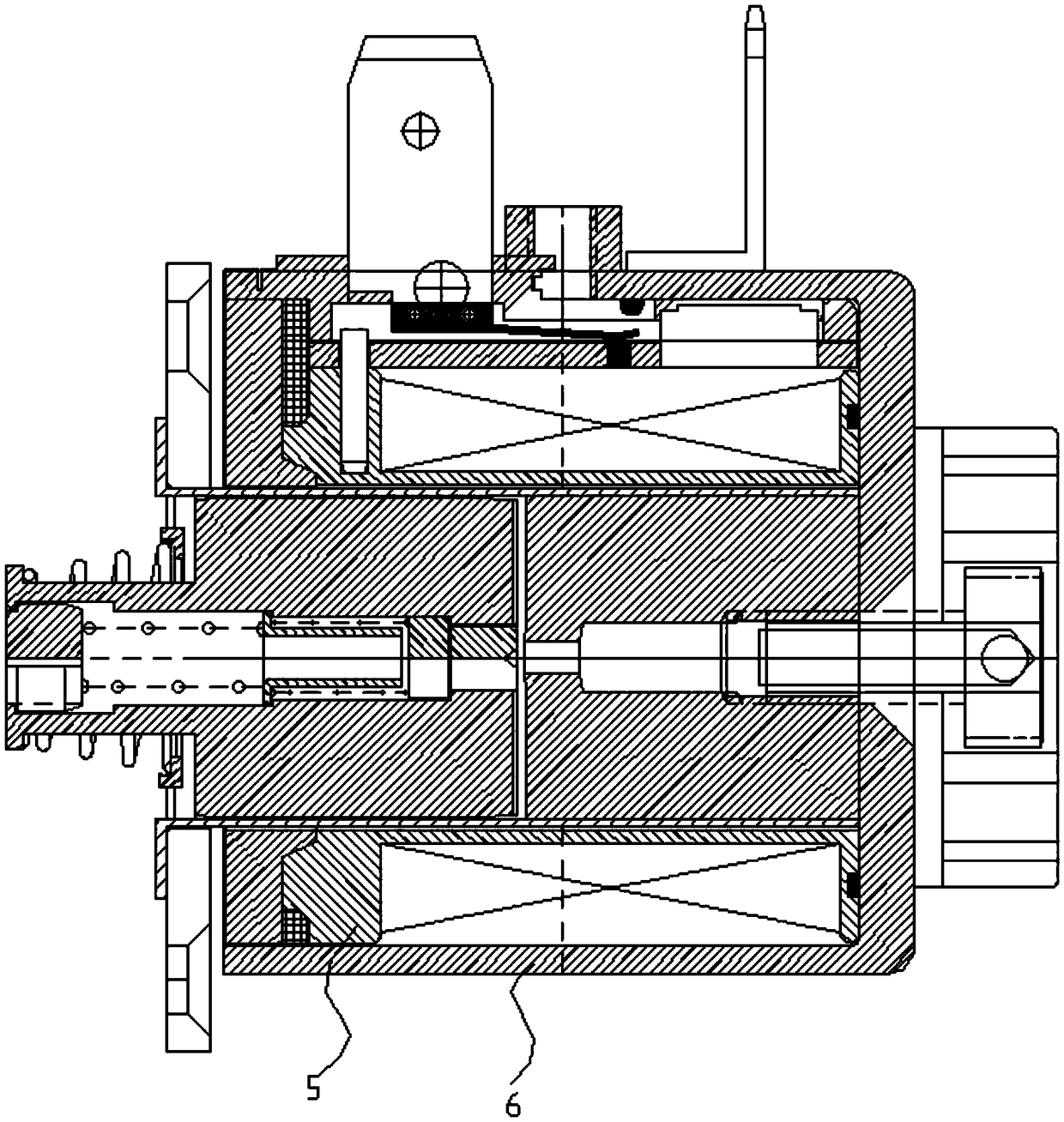

[0053] In this embodiment, the pilot valve assembly includes a sleeve structure 1 , a first moving iron core 2 , an elastic device (not shown), a static iron core 3 , a second moving iron core 7 , a fixing block 74 and a fixing device 4 . The above-mentioned components are mainly introduced below.

[0054] For details, please refer to Figure 10 to Figure 13 , Figure 10 It is a schematic cross-sectional structure diagram of a pilot valve assembly in Embodiment 2 of the present invention; Figure 11 It is a schematic cross-sectional structure diagram of a solenoid valve composed of a pilot valve assembly in Embodiment 2 of the present invention; Figure 12 It is a schematic diagram of a horizontal cross-sectional structure of the first structure of the sleeve structure of a pilot valve assembly in the present invention; Figure 13 It is a schematic cross-sectional structural schematic diagram of a vertical section of the first structure of a sleeve structure of a pilot valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com