High-precision compact integrated joint structure

A joint structure, compact technology, applied in the directions of manipulators, manufacturing tools, joints, etc., can solve the dual requirements of joint lightness and high precision, the external encoder cannot detect the backlash of the reducer transmission process, and the reducer is anti-overturning. The torque has not been enhanced and other problems, to achieve the effect of enhancing the space radiation protection capability, improving the anti-overturning moment and joint output accuracy, and improving the repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

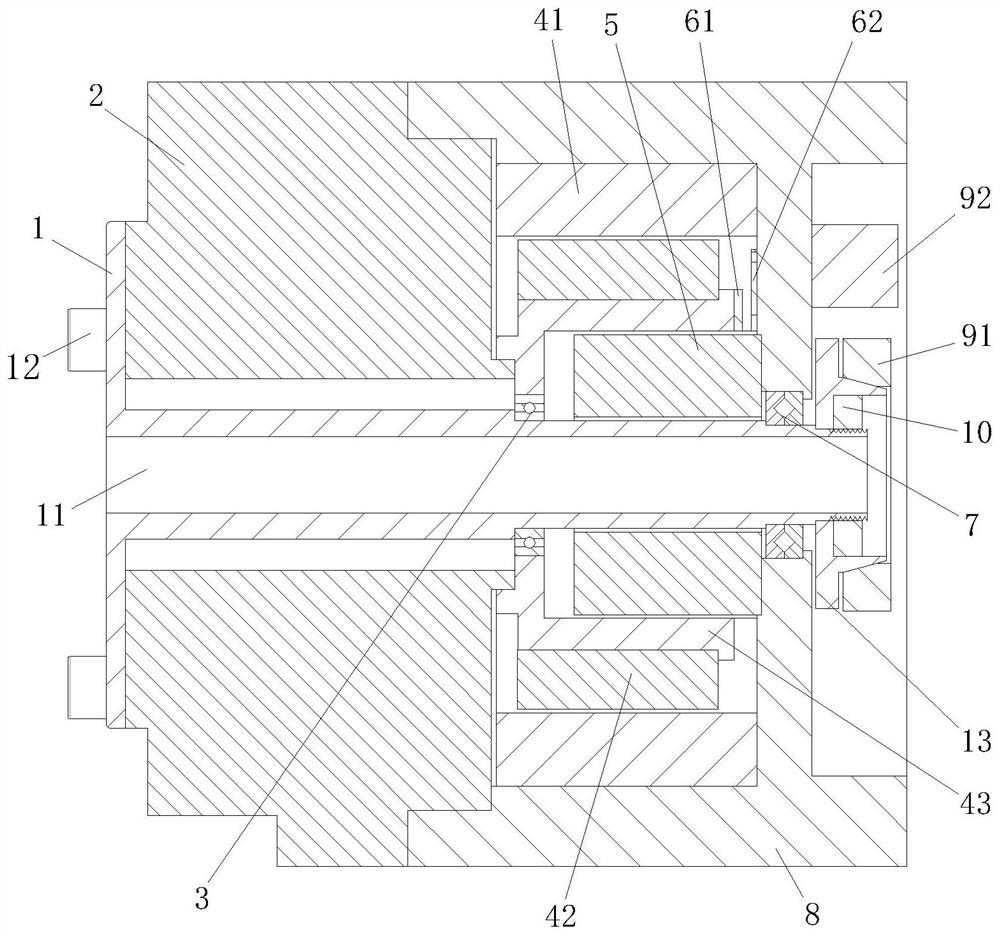

[0026] In this example, refer to figure 1 and figure 2 , the high-precision compact integrated joint structure includes a rotating shaft, a reducer 2, a motor, an integrated brake 5, a relative encoder, an absolute encoder and a joint housing 8, and the input end of the motor and the reducer 2 is assembled and fixed , the rotating shaft is assembled and fixed with the output end of the reducer 2, the joint shell 8 is connected with the reducer 2, and the motor, the integrated brake 5 and the relative encoder are covered inside; the rotating shaft is a hollow feed shaft 1, and its interior has a The middle hole 11 of the cable, the hollow feed shaft 1 runs through the reducer 2 and the joint housing 8, the deep groove ball bearing 3 is arranged between the motor and the hollow feed shaft 1, and the cross roller is arranged between the joint housing 8 and the hollow feed shaft 1 The sub-bearing 7; the absolute encoder is installed on the end of the hollow feed shaft 1 protrudi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com