Joining method and apparatus of binode twisting-pulling mechanism and crust breaking mechanism

A connection method and double anode technology are applied in the field of connection of double anode twist-pulling mechanism and shell-breaking mechanism and their devices, which can solve the problem of not being able to replace double anodes at the same time by twisting and pulling mechanism, and achieve simple structure, enhanced stability, Guaranteed effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

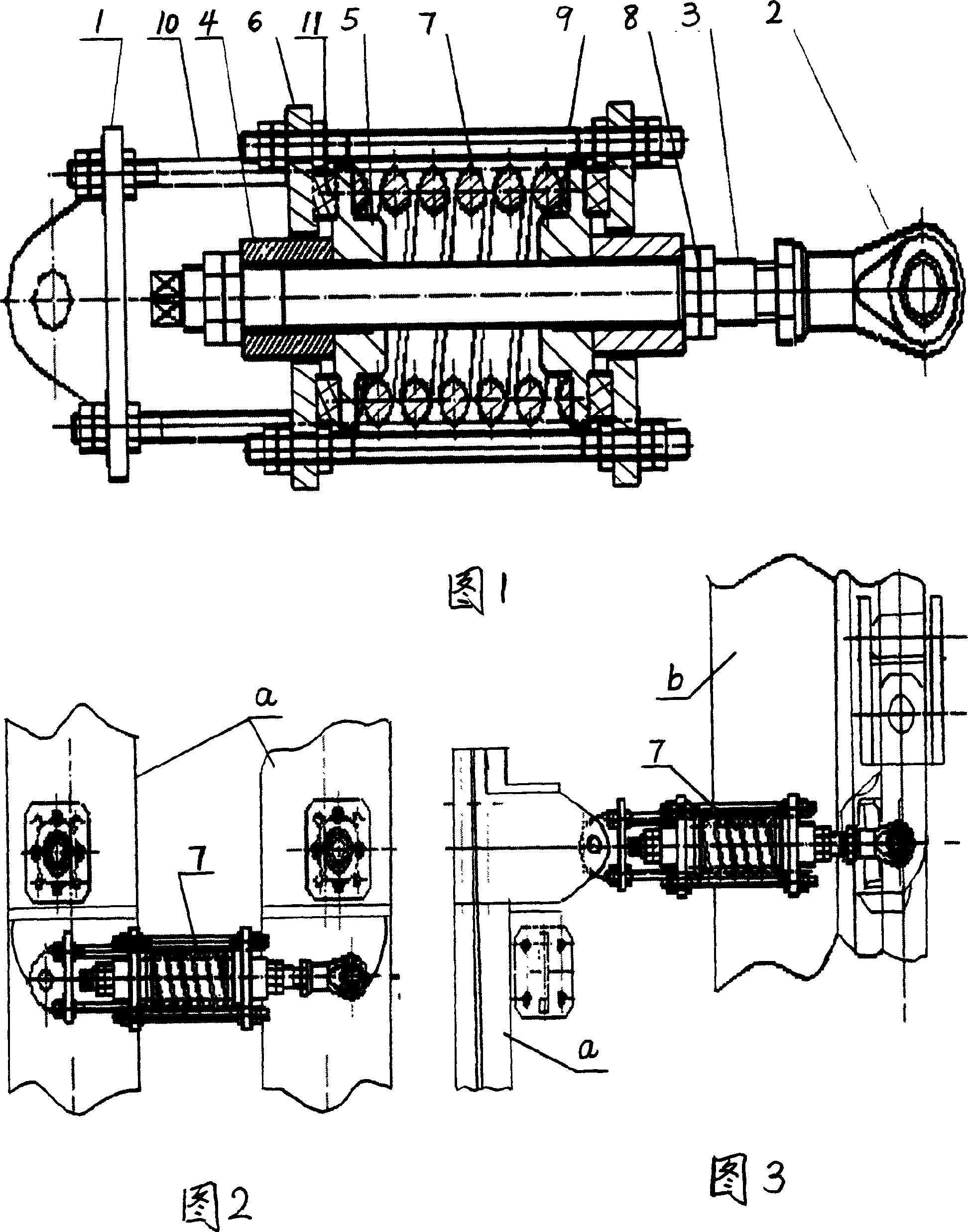

[0010] Embodiment of the present invention: in the production process of adopting dual anodes in an aluminum electrolytic cell, when replacing the dual anodes, between the existing two anode twisting and pulling mechanisms (a) or between the existing anode twisting and pulling mechanisms (a) and shell-beating mechanism (b) all adopt the method of spring-type elastic connection to connect respectively; The specific spring-type elastic connection device is preferably made into the elastic connection device of the following structure by the following method:

[0011] First install the spring seat (5) on both ends of the spring (7), install a nut on each connecting screw (9), and then insert the screw at the end of the nut installed into the hole of the left flange (6) , and then install two nuts and lock them; install a buffer rubber pad (11) between the left end flange (6) and the spring seat (5), and install another on the other end of each connecting screw (9). Screw the nut t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com