High-strength polyethylene pipe for building

A high-strength polyethylene, construction technology, applied in the direction of pipeline protection, pipe/pipe joint/fitting, pipeline damage/wear prevention, etc., can solve the local extrusion of the outer pipe, the damage of the outer pipe, and reduce the The wear resistance of the pipe wall and other issues can be avoided to avoid excessive deformation and damage, improve the service life and reduce the probability of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

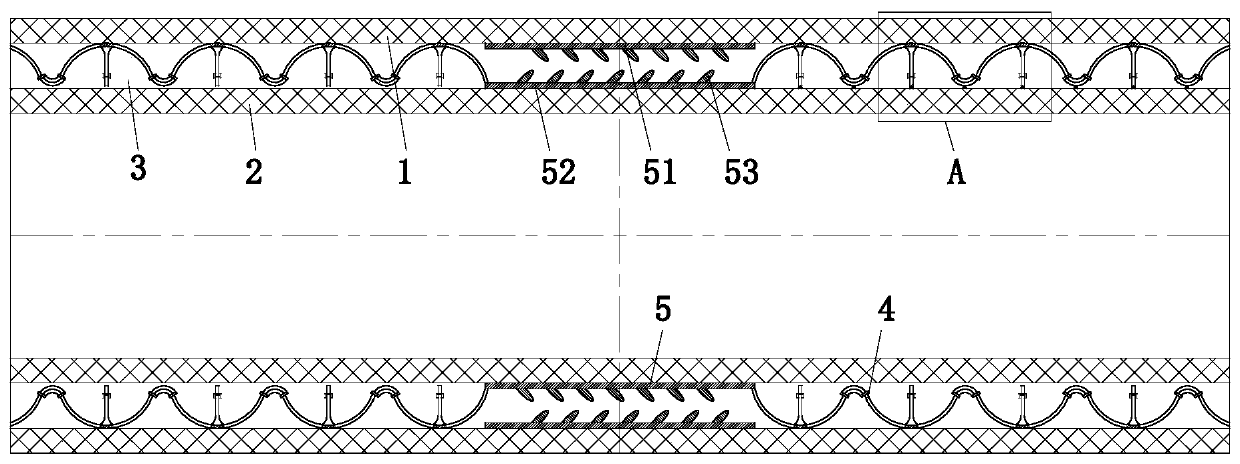

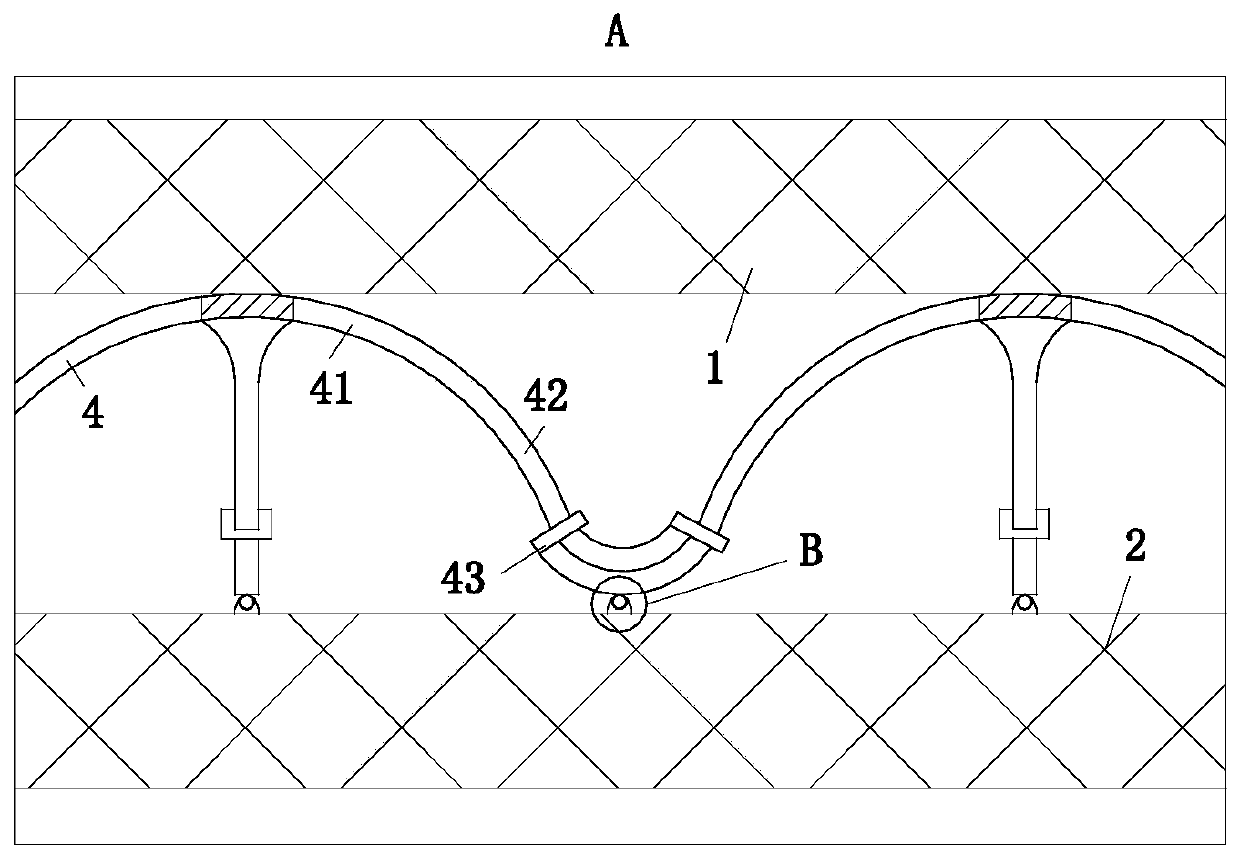

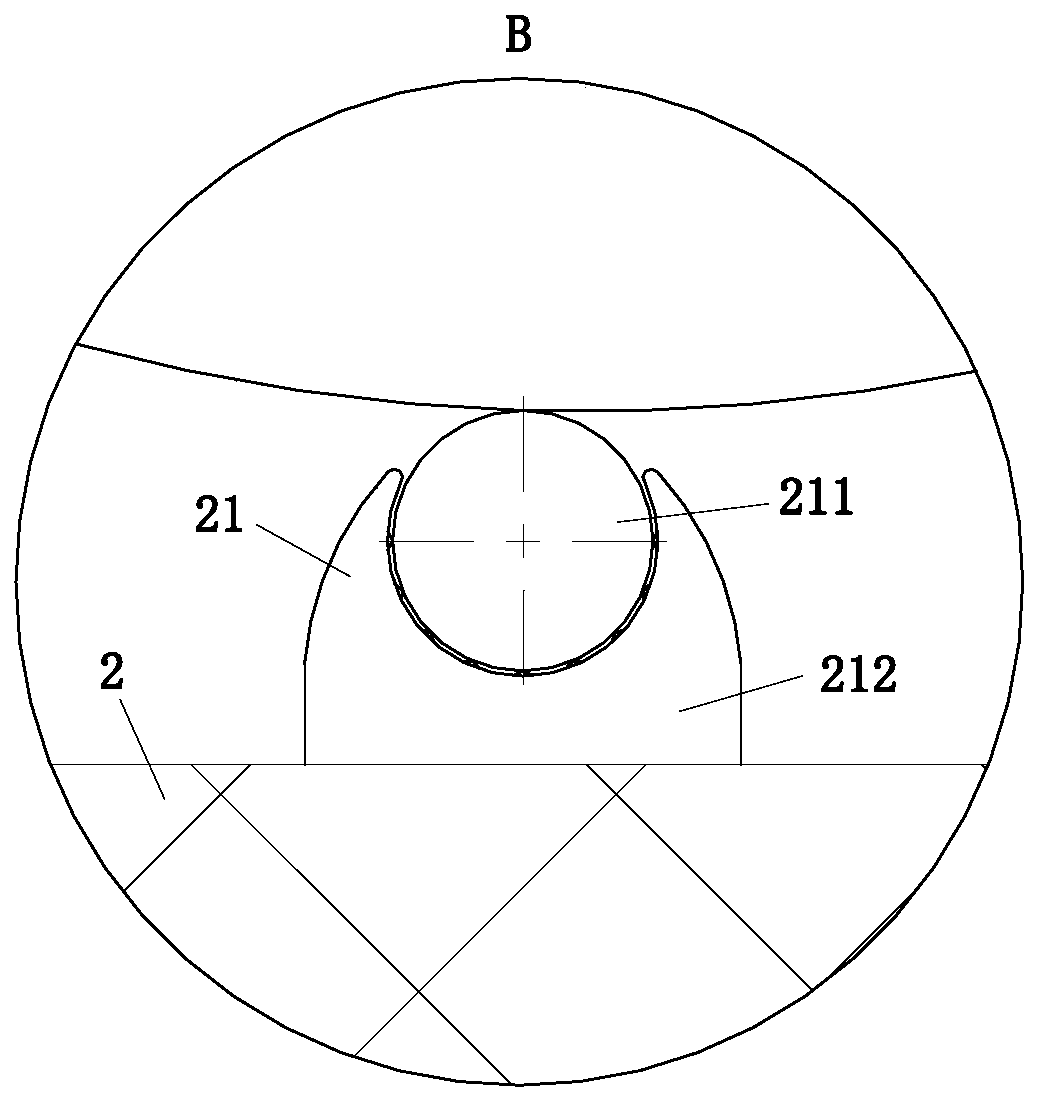

[0025] Such as Figure 1 to Figure 6As shown, a high-strength polyethylene pipe for construction includes an outer pipe body 1, an inner pipe body 2, a buffer module 4 and a support module 5; the outer pipe body 1 is sleeved on the outside of the inner pipe body 2, and the outer pipe body An annular cavity 3 is formed between the inner wall of the body 1 and the outer wall of the inner pipe body 2; a buffer module 4 and a support module 5 are arranged inside the annular cavity 3; the support module 5 includes a No. 1 annular steel sheet 51, No. 2 annular steel sheet 52 and plug-in tooth 53, No. 1 annular steel sheet 51 is arranged on the inner wall of outer pipe body 1 middle part, No. 2 annular steel sheet 52 is arranged on the outer wall of inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com