Numerical control machine for processing huge conical gear with curved teeth

A technology of CNC machine tools and curved teeth, which is applied in the field of CNC machine tools, can solve problems such as difficulty in improving machining accuracy, difficulty in workpiece installation, clamping, positioning and alignment, insufficient rigidity and stability of machine tools, etc., and achieves convenient positioning and compact layout of machine tools , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

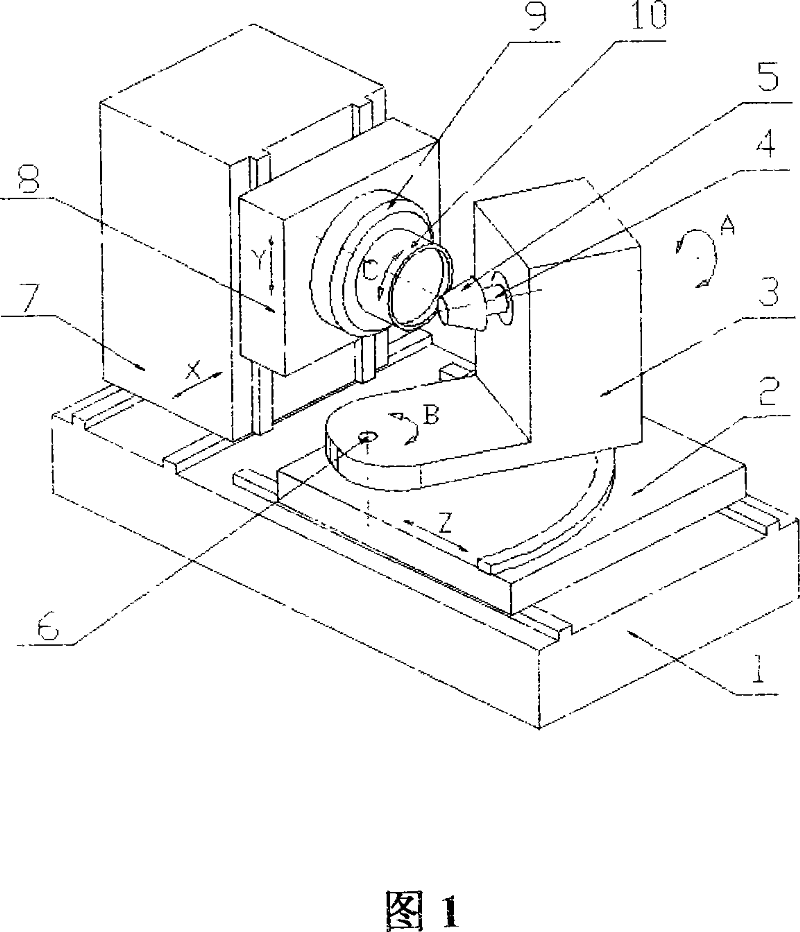

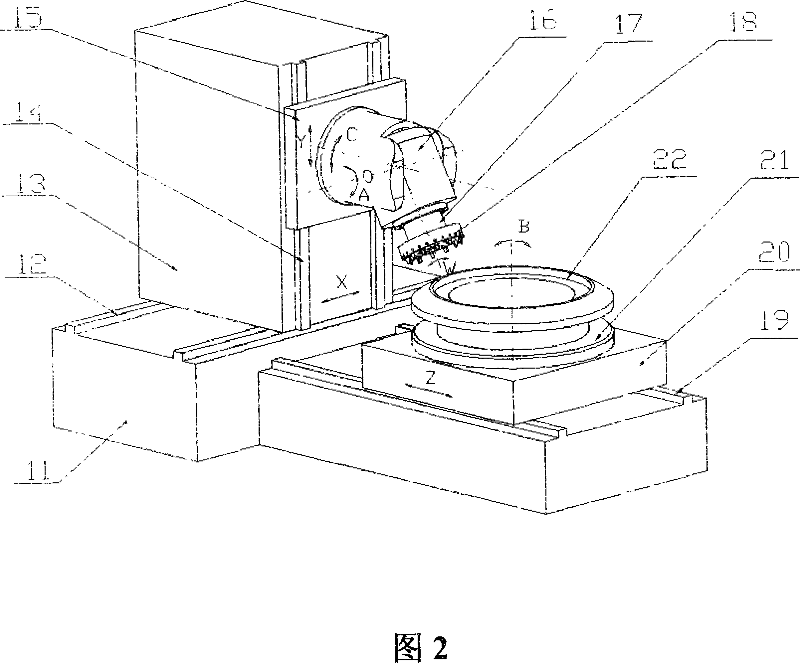

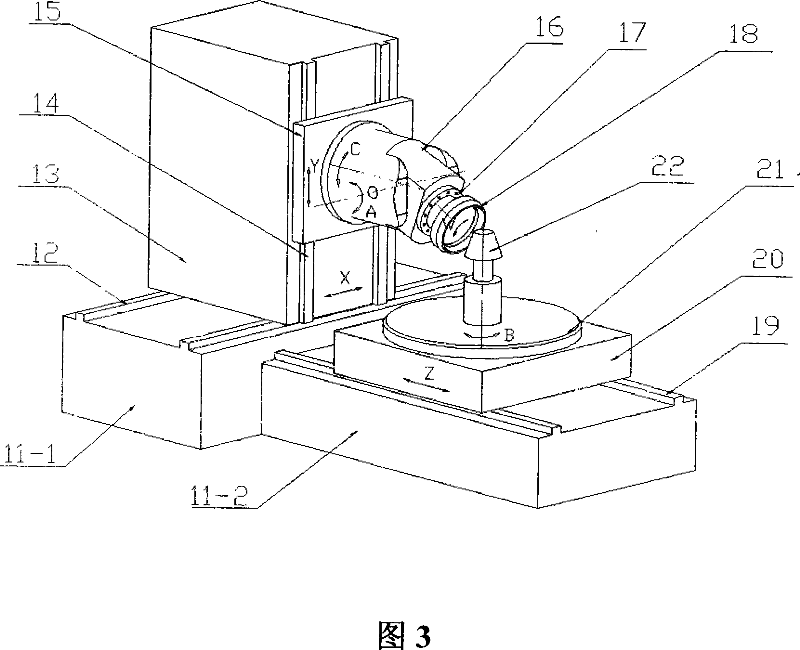

[0023] The embodiments of the present invention are shown in accompanying drawings 2, 3 and 4, and the present invention will be further described below in conjunction with the embodiments. In the attached picture:

[0024] 1-bed; 2-Z-axis sliding table;

[0025] 3-Workpiece box 4-A axis;

[0026] 5-workpiece; 6-axis B;

[0027] 7-X-axis sliding table; 8-Y-axis sliding table;

[0028] 9-C axis; 10-tool;

[0029] 11-machine bed; 12-X-direction linear guide;

[0030] 13-X-axis sliding seat; 14-Y-direction linear guide rail;

[0031] 15-Y-axis sliding seat; 16-tool seat;

[0032] 17-machine tool spindle; 18-tool;

[0033] 19-Z-direction linear guide rail; 20-Z-axis slide seat;

[0034] 21-rotary table; 22-workpiece;

[0035] 11-1-X to the bed; 11-2-Z to the bed;

[0036] 16-1-tool seat fixed body; 16-2-tool seat C-axis swing body;

[0037] 16-3-A-axis swinging body of the tool holder.

[0038] Referring to Fig. 2, the large-scale curved bevel gear processing machine t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com