Inductance coil and laser-cutting manufacturing method of inductance coil

A technology of inductance coil and laser cutting, which is applied in the direction of transformer/inductor coil/winding/connection, manufacturing tools, welding equipment, etc., and can solve the problems of open circuit failure, influence, and complicated manufacturing process at the lead-out welding place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0096] The present invention will be described below in combination with specific embodiments and with reference to the accompanying drawings.

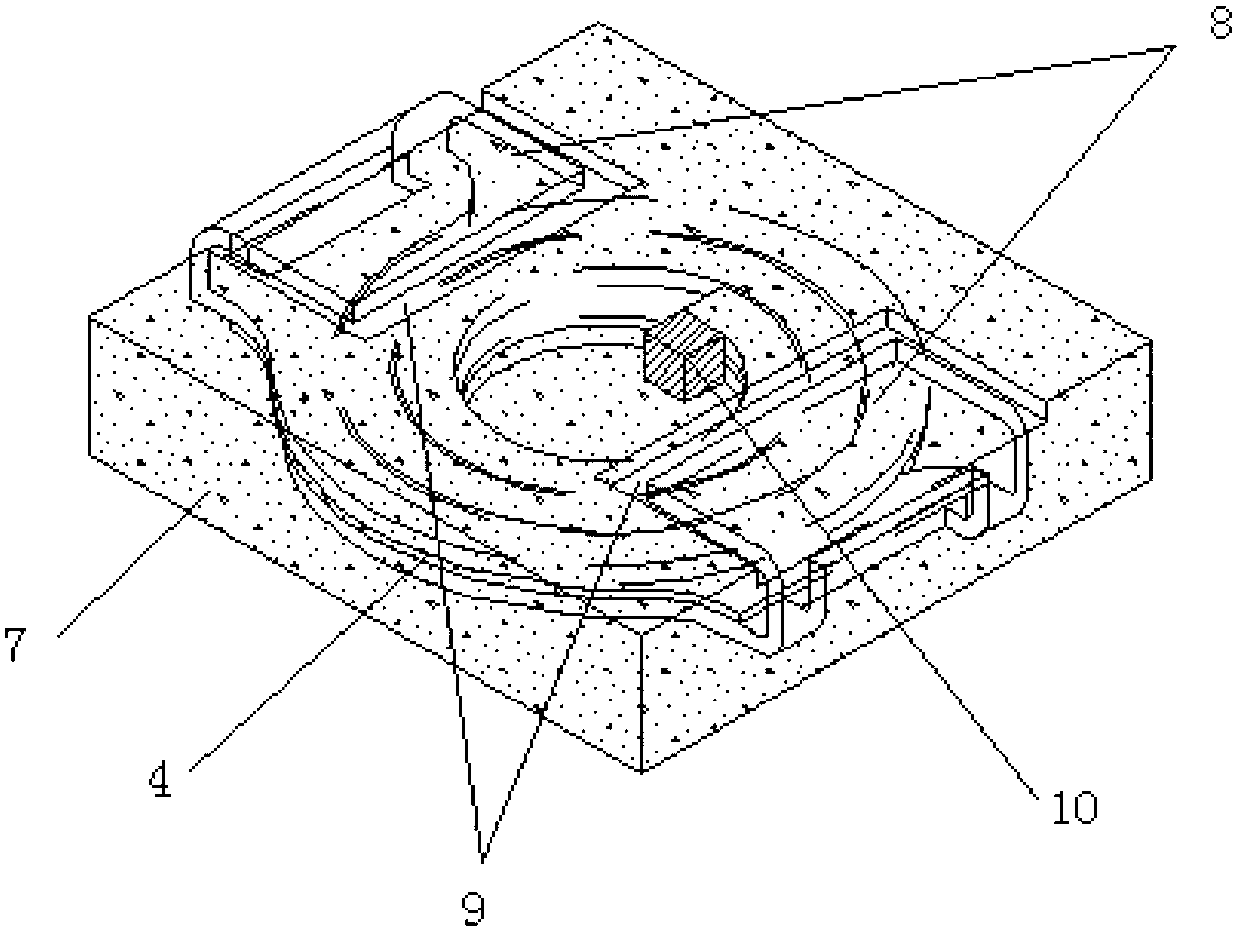

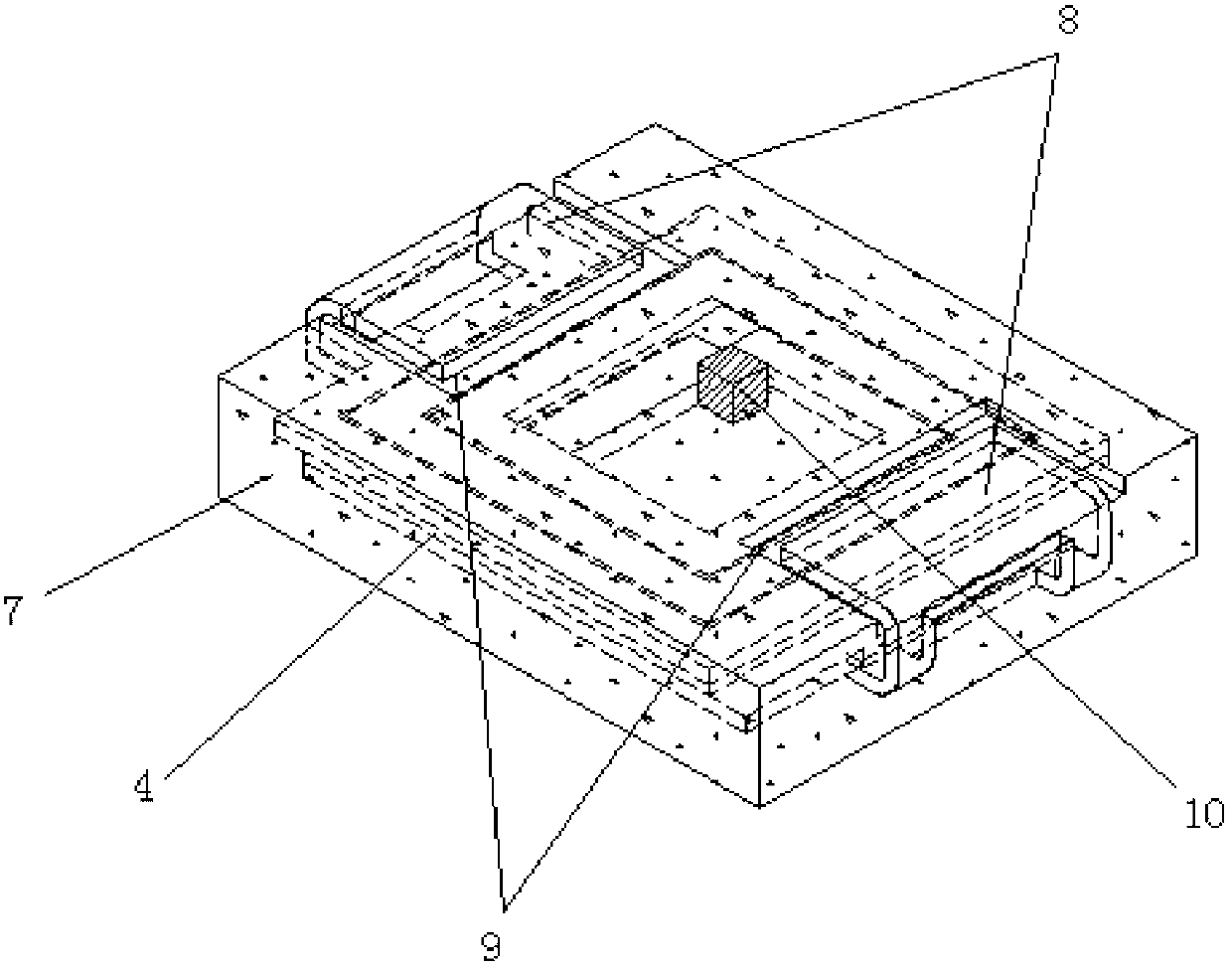

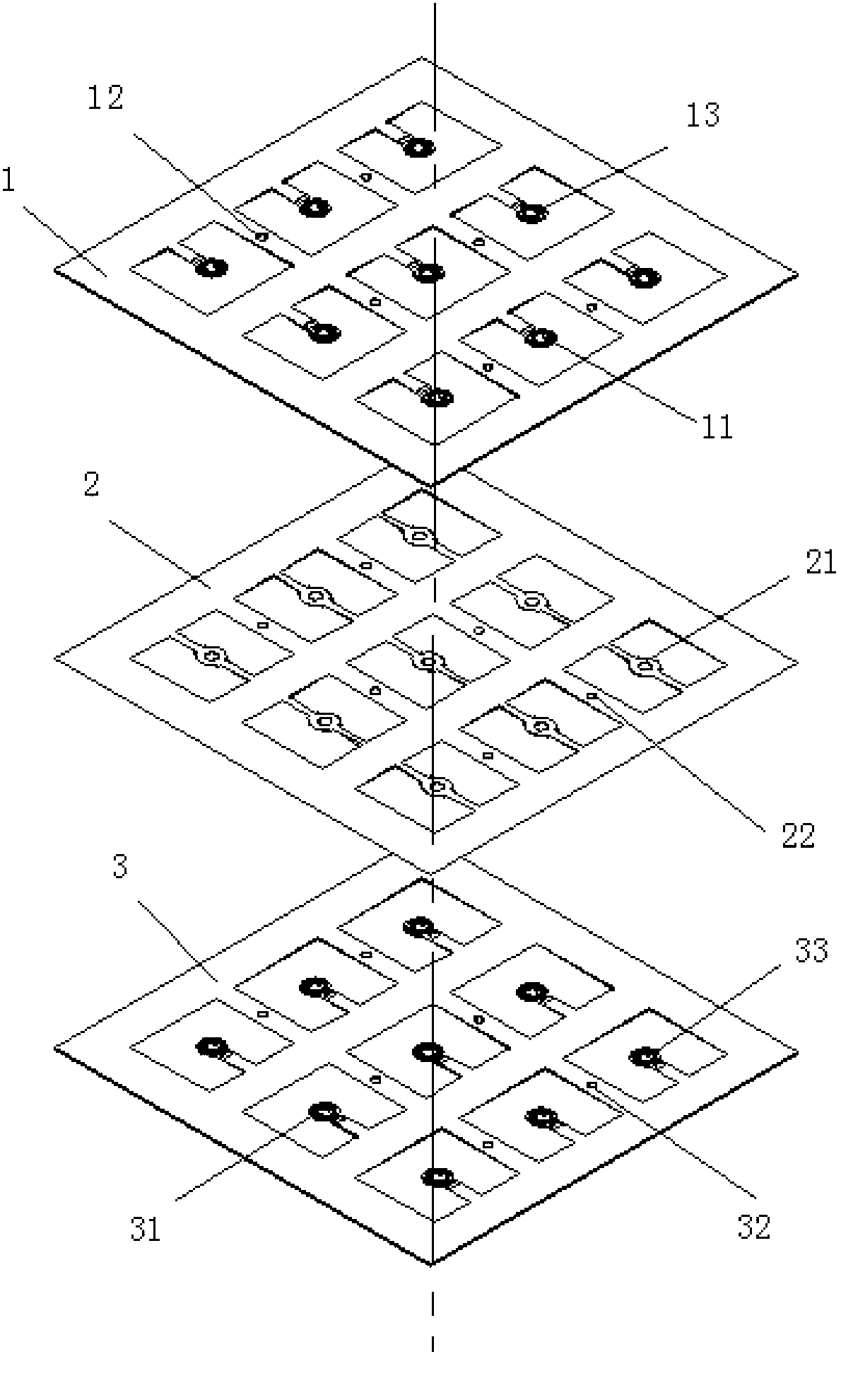

[0097] a kind of like Figure 1-12 The shown inductance coil includes an upper copper foil coil 11 and a lower copper foil coil 31 with an insulating coating on the outer surface for insulation treatment, and a high temperature resistant organic film arranged between the layers of the upper copper foil coil 11 and the lower copper foil coil 31 2, and the magnetic material layer 7 wrapped around the upper copper foil coil 11 and the lower copper foil coil 31, the passing area of the upper copper foil coil 11 and the lower copper foil coil 31 is 0.0010mm 2 The upper coil welding preset connection point 13 and the lower coil welding preset connection point 33 are connected by ultrasonic welding to ensure the reliability of welding. figure 1 , 2 The welding area 10 in is the connection point of the upper copper foil coil 11 and the lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com