Method for preparing grinding-free drill head and drill head

A technology for grinding drills and drills, which is applied to drilling/drilling equipment, parts of boring machines/drilling machines, twist drills, etc., which can solve the problems of easy deformation of the groove side wall, insufficient life of the drill body, and loose connection, etc. , to achieve the effect of solving manufacturing difficulties, solving regrinding problems, and easy positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

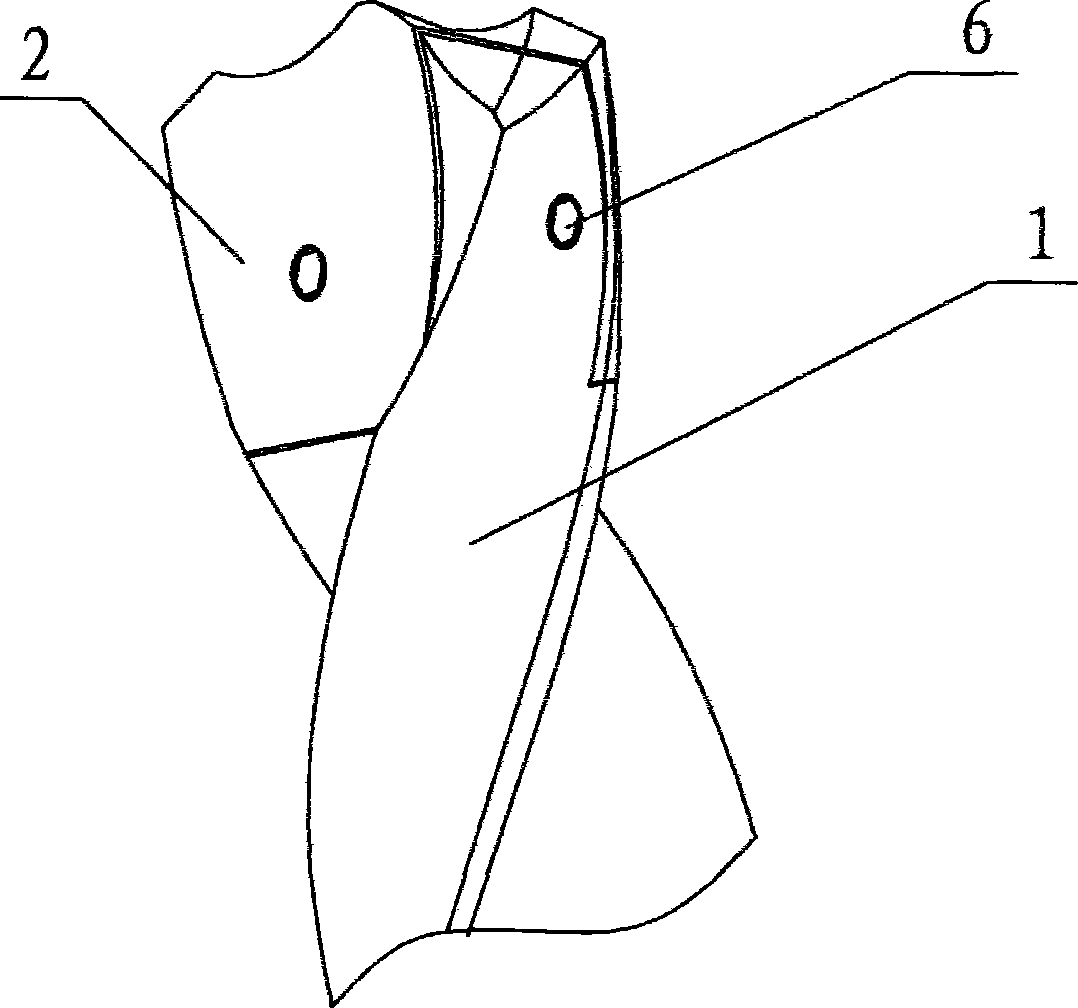

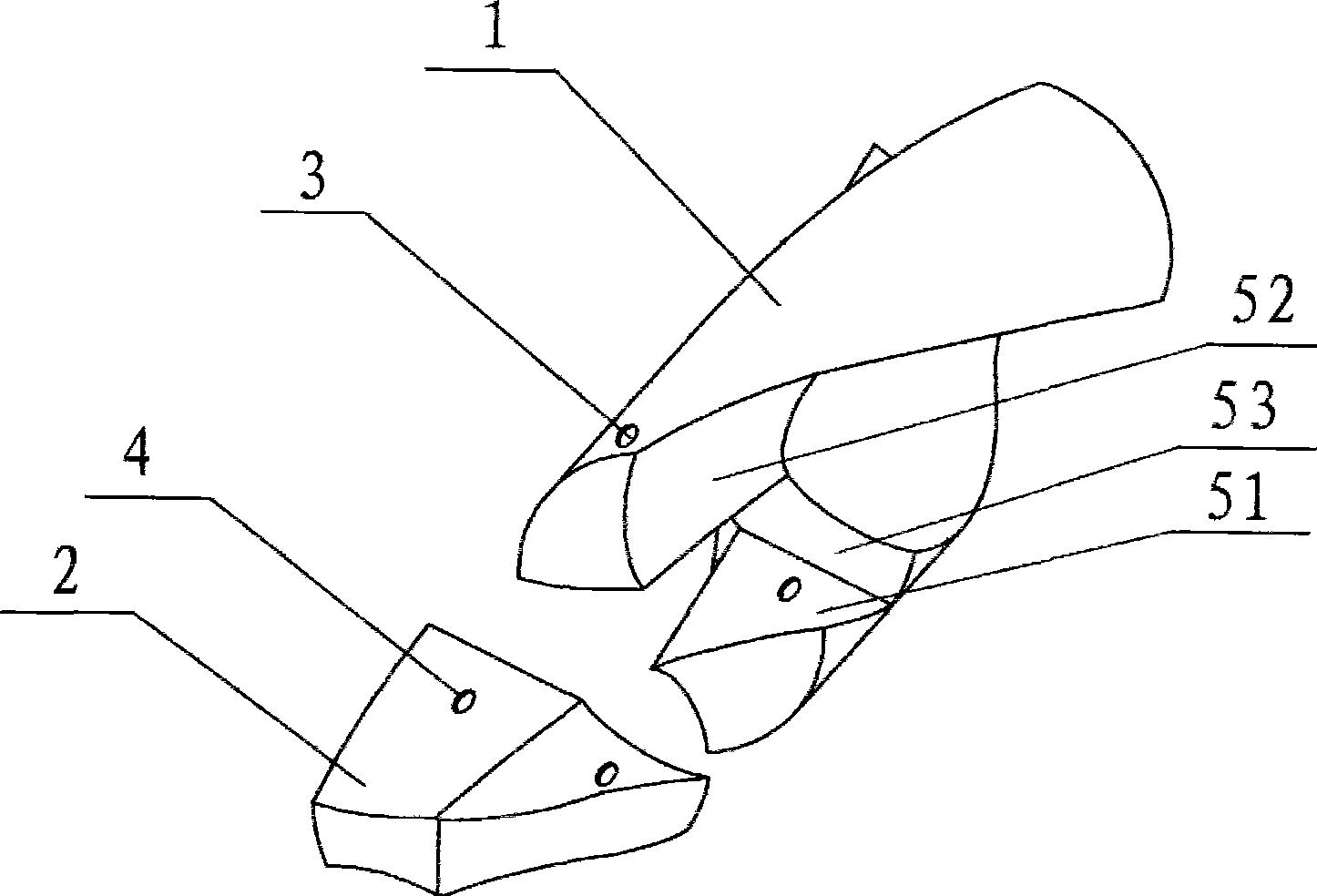

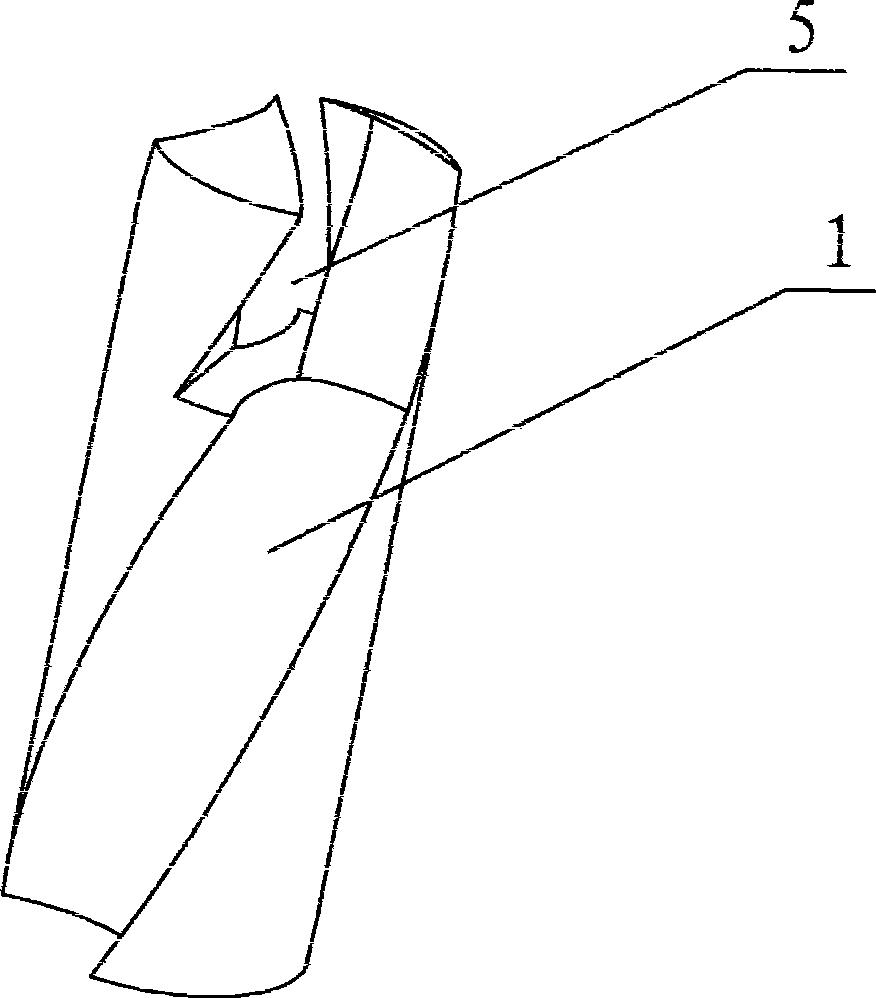

[0033] see Figure 1 to Figure 9 , the preparation method of the wear-free drill bit provided by the present invention, it comprises drill body 1 and the cutting blade 2 that is detachably connected at the front end of this drill body, and it comprises the following steps:

[0034] (1) According to the set depth and width, a helical groove 5 for accommodating the cutting blade 2 is provided at the front end of the drill body 1, and the inner sidewalls 51 and 52 of the helical groove 5 are arc Shaped surface, and the two arc-shaped surfaces are centrally symmetrical, so that the overall profile of the spiral groove 5 is "S"-shaped; each of the described arc-shaped surfaces 51, 52 is a parallelogram after being unfolded;

[0035] (2) Prepare a cutting blade 2 that is compatible with the shape of the inner wall of the spiral groove 5 on the drill body 2 and whose side walls are two symmetrical arc surfaces;

[0036] (3) Put the cutting blade 2 into the drill body helical groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com