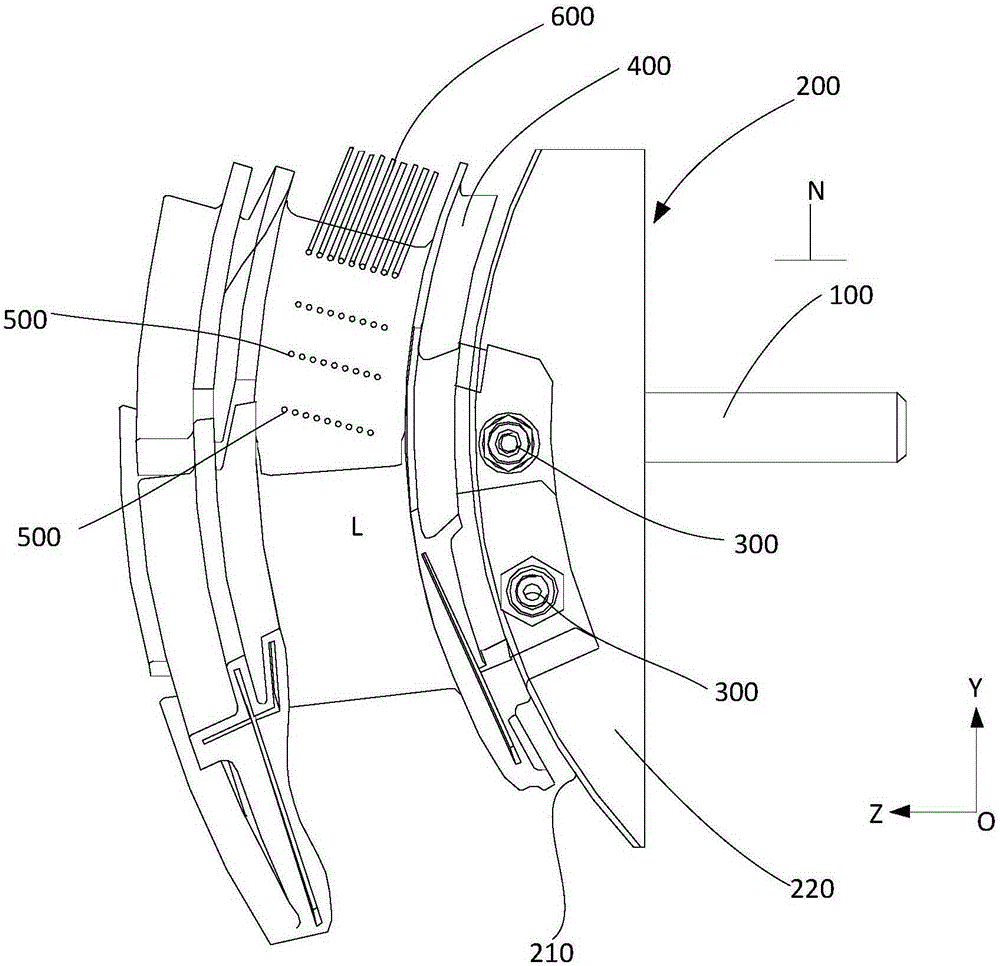

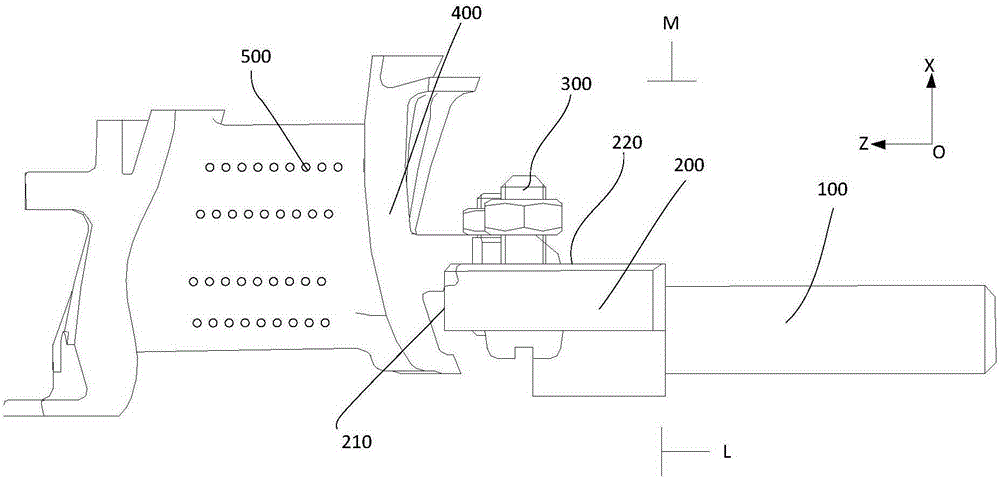

Auxiliary fixture for gas turbine primary guide vanes and film hole measuring method

A technology of guide vanes and gas turbines, applied in the direction of measuring devices, manufacturing tools, workpiece clamping devices, etc., can solve the problems of inconvenient measurement of tiny air film holes and difficulty in determining the measurement coordinate system, so as to facilitate the determination of the coordinate system and the convenience of measurement , The effect of easy positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0038] The shape, position and size of the first-stage guide vanes of the gas turbine are designed based on the stacking axis, including the angle of the gas film hole and the structure of the inner cavity. However, it is difficult to directly determine the center of the stacking axis. The positioning reference is complex, and currently only a compound optical coordinate machine can be used to detect whether the blade size meets the requirements of the drawing. However, the air film hole structure of the gas turbine first-stage guide vane is complex, the hole diameter is small, and there are spatial positions and angles. If the contact probe of the three-coordinate machine is used alone, there will be interference when measuring tiny shapes. Even if...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com