A cutting machine for glass products

A technology for glass products and slitting machines, which is applied to glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of horizontal positioning of glass that cannot be loaded, sensors are prone to failure, and cutting efficiency is affected. Reliable, unobstructed, smooth motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

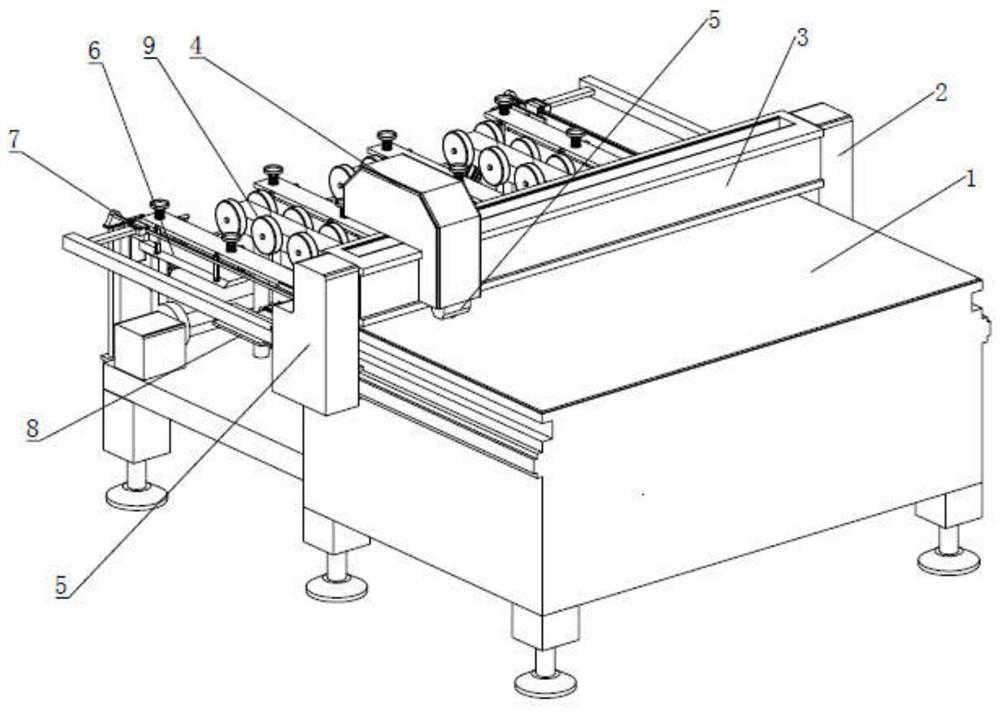

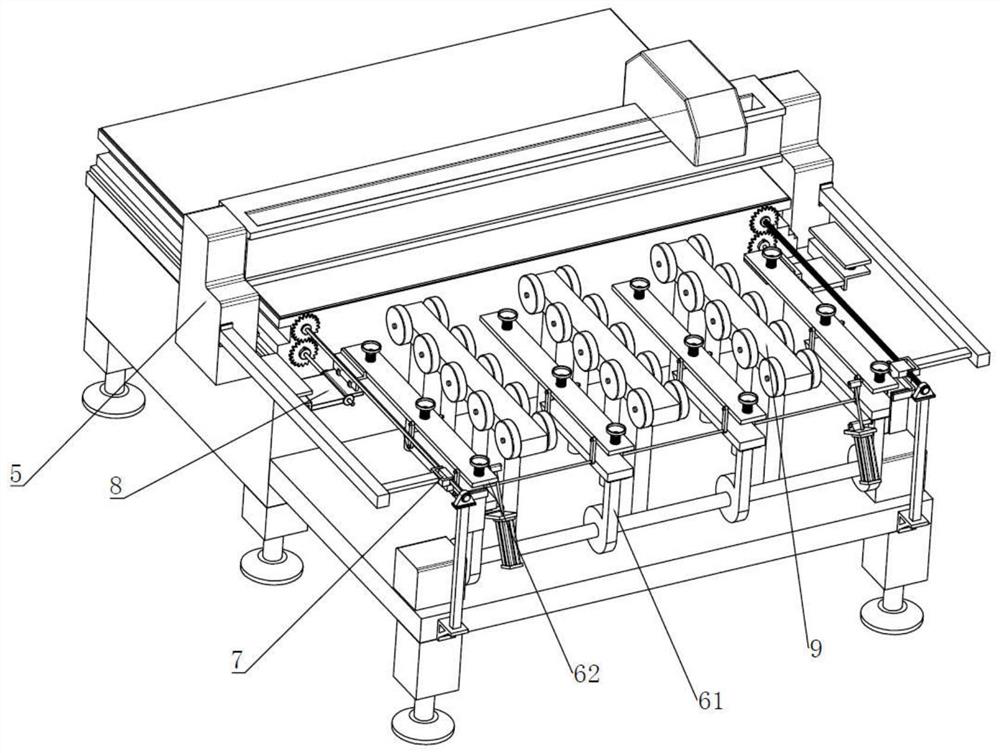

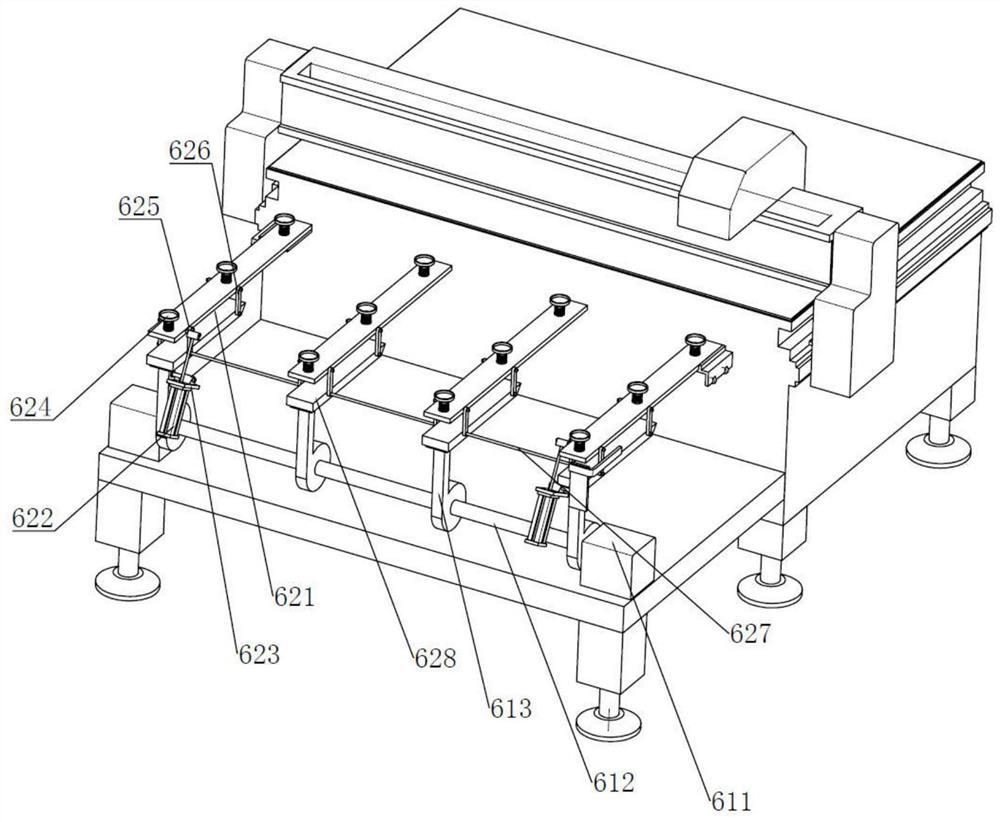

[0027] Such as Figure 1-6As shown, in this embodiment, the present invention provides a slitting machine for glass products, which includes a machine platform 1, longitudinal guide rails arranged on both sides of the machine platform 1, and sliding rails slidably installed on the longitudinal guide rails. Seat 2, cutting bridge 3, knife rest 4 slidably mounted on the cutting bridge 3, cutting knife 5 installed on the lower part of the knife rest 4, and automatic loading mechanism 6, and the cutting bridge 3 is laterally connected on both sides between the sliding seats 2, the cutting knife 5 is located on the machine table 1, and the automatic loading mechanism 6 includes an overturning loading mechanism 61 and a sucker moving mechanism 62, which is characterized in that: the automatic loading mechanism The mechanism 6 is arranged on the rear side of the machine table 1, the cutting bridge 3 is located above the rear side of the machine table 1 in the initial state, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com