Flexible axle boxes and assembling method thereof, and bogie

A flexible shaft and bogie technology, applied in the field of bogies, can solve the problems of limited effect, increase train derailment, reduce the elastic suspension effect of axle boxes, etc., and achieve the effects of easy installation, restraining snaking motion, and increasing the critical speed of instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

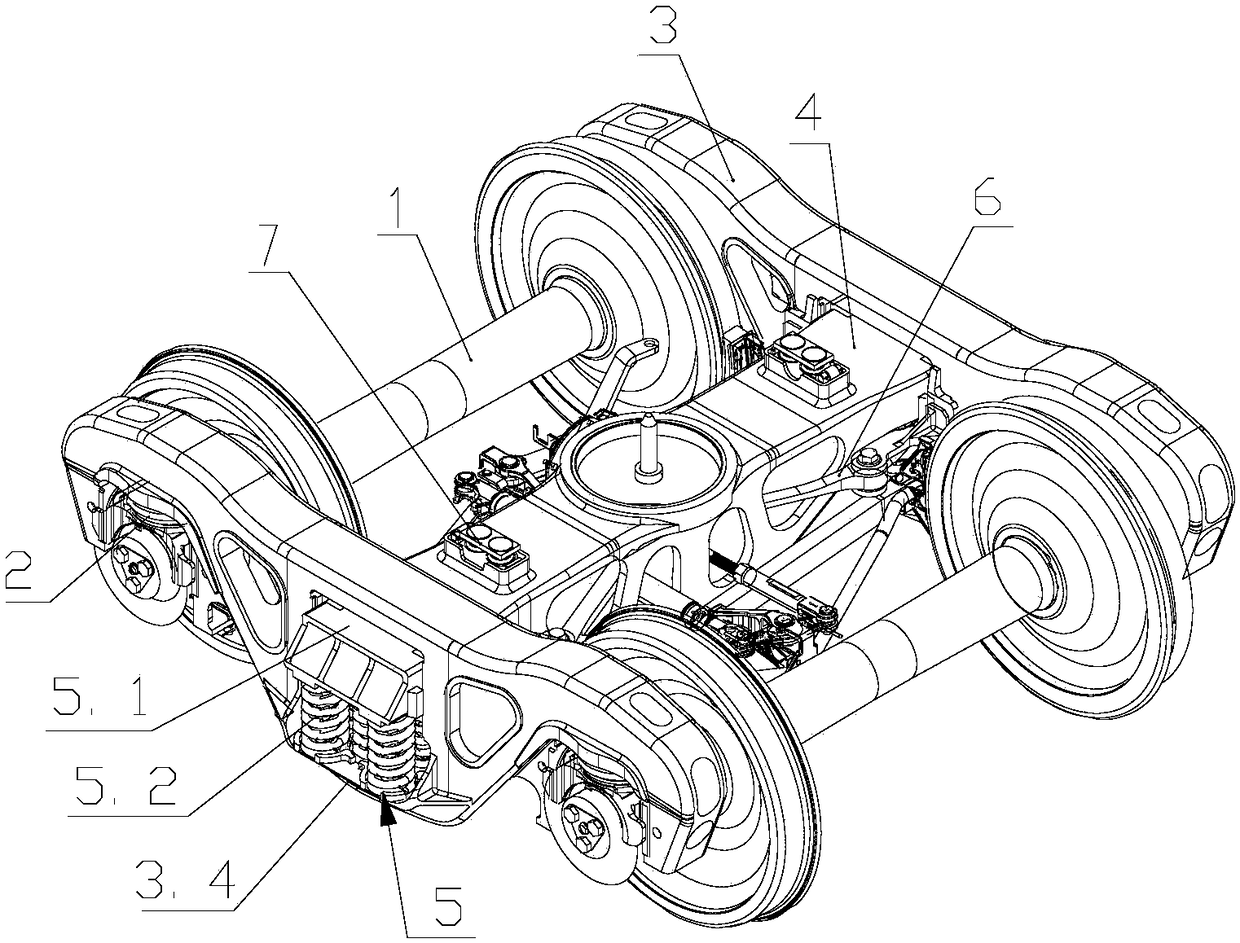

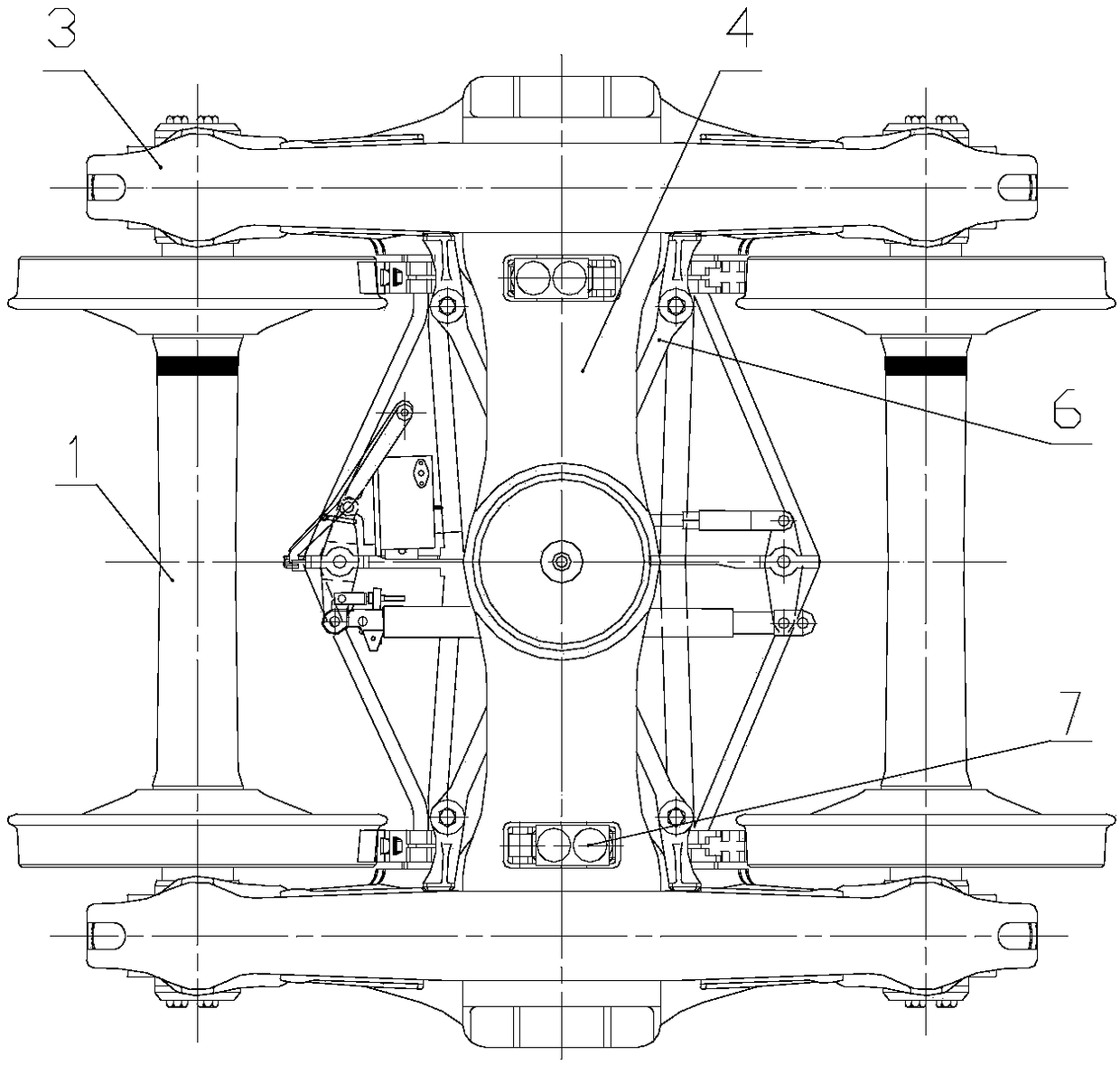

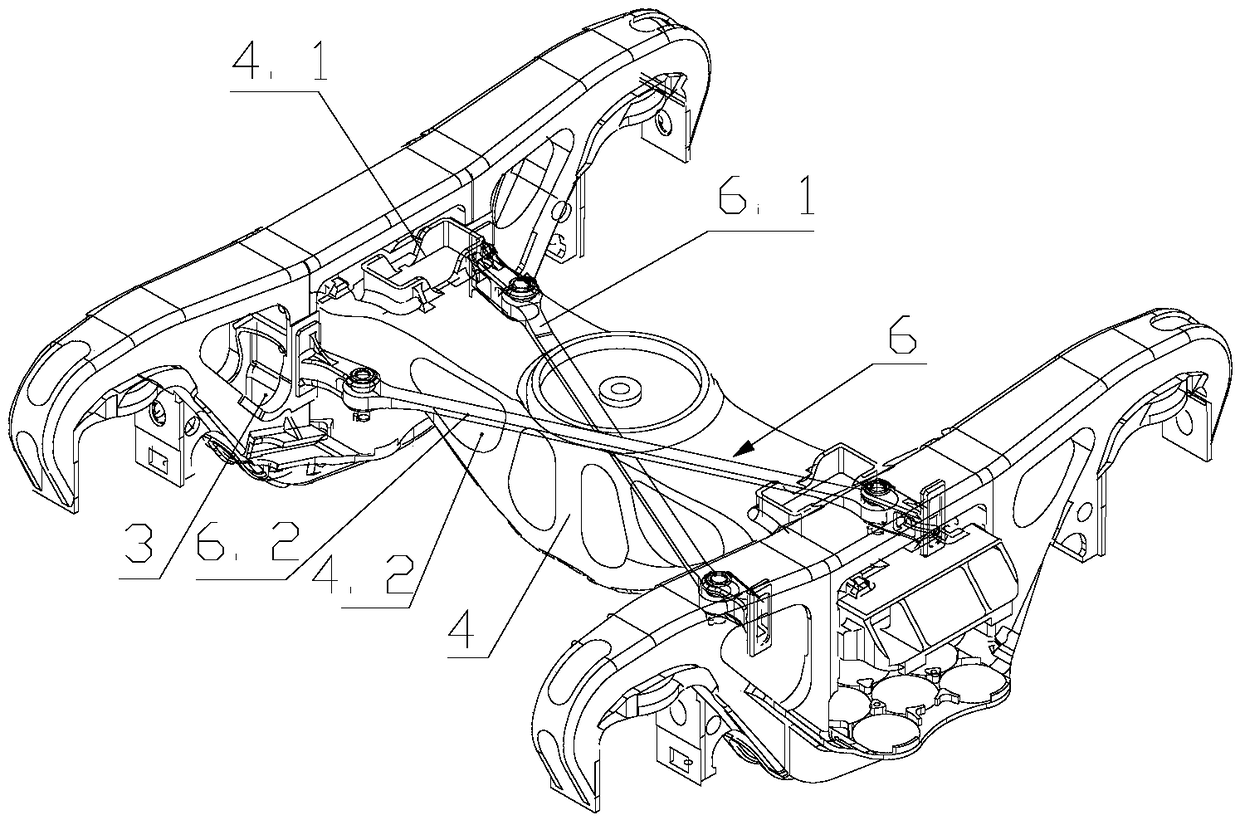

[0035] Such as Figure 1~3Shown in is a truck bogie with flexible axle box suspension, including two sets of wheels 1, and flexible axle boxes are arranged symmetrically on both sides of each wheel set 1, and the flexible axle box includes a flexible axle box body 2, two on the same side The flexible axle box body 2 is provided with a side beam component 3, and a cross beam component 4 arranged perpendicularly to the two side beam components 3 is arranged between the side beam components 3 on both sides; The middle part of the beam composition 3; the X-shaped connecting rod 6 is arranged under the cross-beam composition 4, and the axial ends of the X-shaped connecting rod 6 respectively pass through the webs on both sides of the cross-beam composition 4 and are fixedly connected with the side beam composition 3. The X-shaped connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com