Five-axis numerical control grinding machine

A technology of CNC grinding machine and sliding block, which is applied to grinding machines, grinding machine parts, grinding workpiece supports, etc. Shake-reducing, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

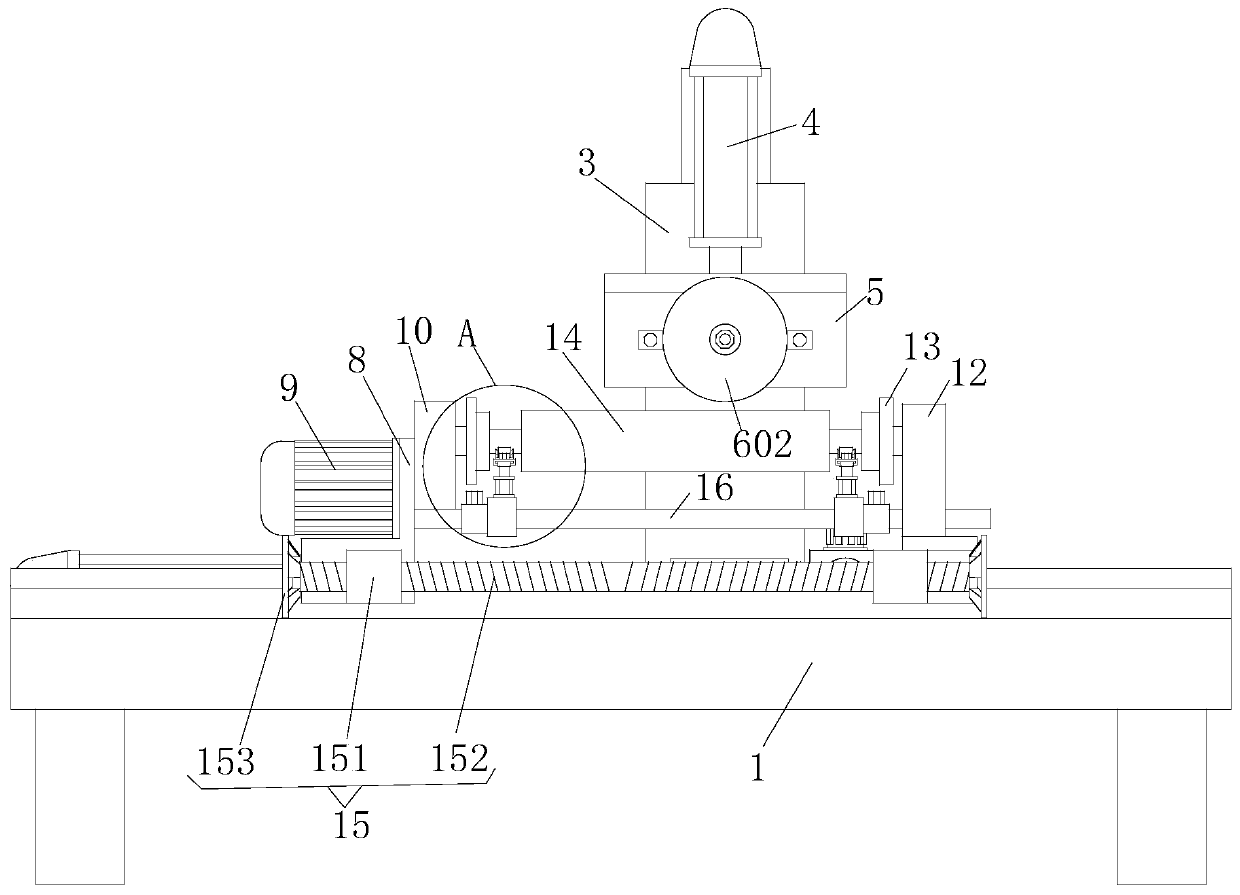

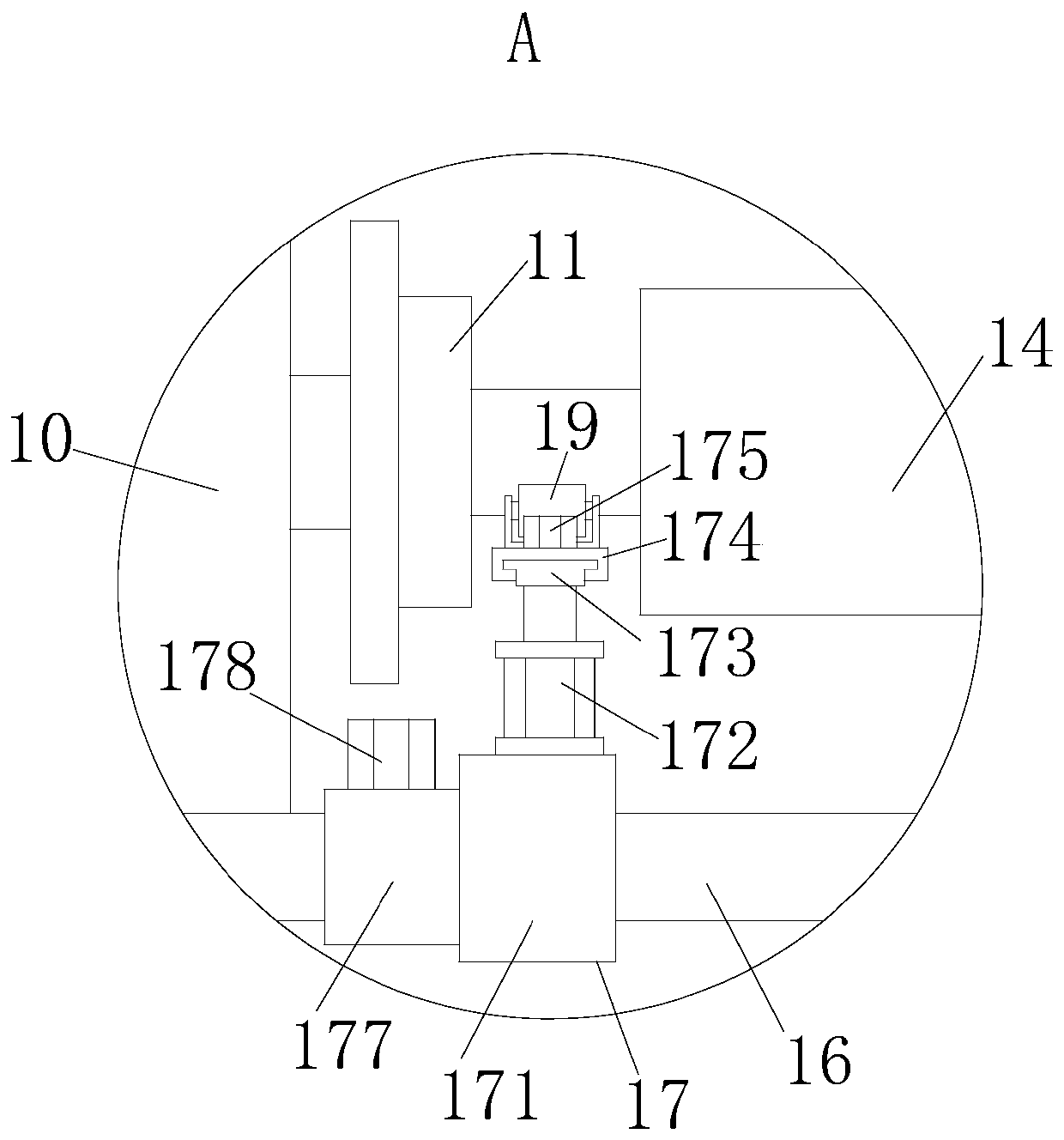

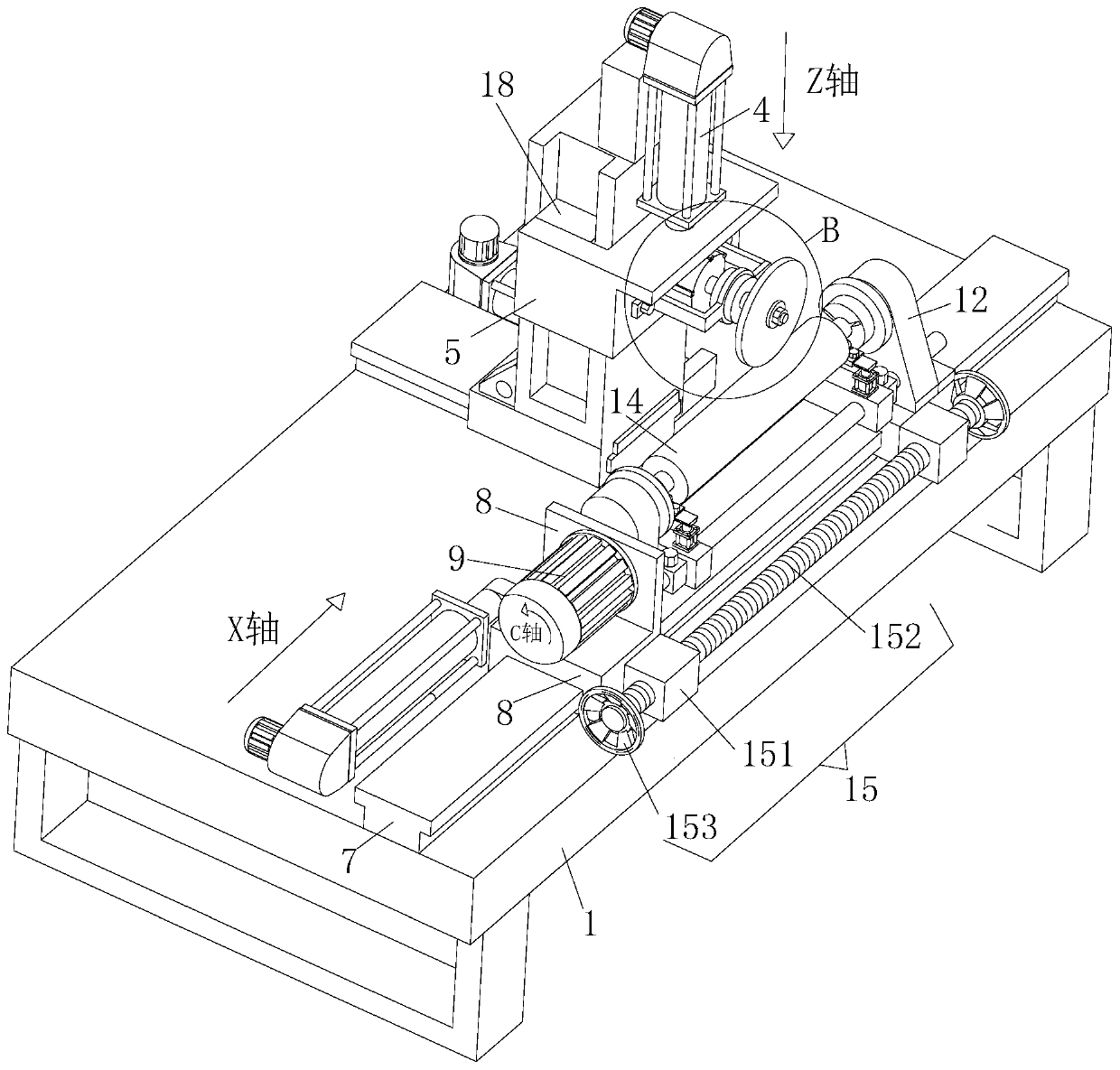

[0027] As an embodiment of the present invention, the track mechanism 2 includes a second slide rail 201; the second slide rail 202 is fixedly connected to the rear side of the top of the console 1; the surface of the second slide rail 201 is slidably connected There is a driving slider 202; the driving slider 202 is fixedly connected to the bottom of the longitudinal support plate 3; the side of the driving slider 203 is fixedly connected to a first electric cylinder 203; the bottom of the first electric cylinder 203 is fixedly connected to At the top of the console 1; during work and processing, the first electric cylinder 203 is controlled by the controller of the peripheral device, the first electric cylinder 203 pushes the driving slider 203, and the driving slider 203 synchronously drives the longitudinal support plate 3 to the processing worker. The position plays the role of adjusting the position of the longitudinal support plate 3, and realizes the driving in the Y-ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com